Mista_Sparkle

Well-Known Member

Reading the forums, I noticed that a lot of people were feeling somewhat guilty about all the water that they go through chilling their beer. As a good engineer interested in thermodynamics, I decided that I would take a shot at tackling this problem. Since many of the people with the water issues were in warm climates with fairly warm water temperatures tended to be in the southwest, I decided that an evaporative chiller would be the easiest and most effective way to go.

My cooling system consists of the following parts connected in this order

1: High head pump (115' head, 650GPH))

2: Wort chiller (I used an immersion chiller but a counterflow or other isolated chiller would work as well)

3: Spray head (constructed out of PVC, 1/8" hole with flat surface to disperse water, I used a 14 Ga. copper wire)

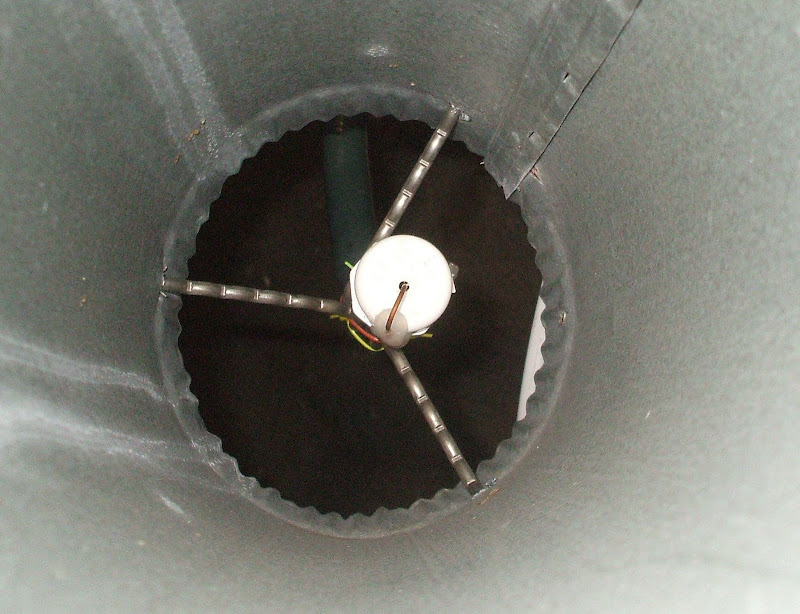

4: Spray Column (used some circular duct from an old furnace install)

5: Reservoir (An old trash can in my case, I cleaned it, but it doesn't really matter)

The idea is to pump the water through the chiller and disperse it into a fine mist while moving massive amounts of air to evaporate as much water as possible. Each pond of water evaporated removes about 1000 BTU from the environment in the form of a temperature drop. With evaporative cooling, it is possible to cool the working fluid down to the dew point so that means you can cool below the outside temperature which can be very significant in dry climates.

I have some pics of the rig following

(if you don't see the facebook pics ill load them up somewhere else)

The rig worked very well, however it should be noted that we were working in 20 degree weather. We were able to cool 5 gallons of beer from 180 to 80 in about 6 minutes which is on par with what I was able to achieve with straight well water. We did have a failure in the system as one of the hoses obtained from the trash essentially burst in use but lasted long enough for some results.

Some other relevant info:

With the mist nozzle on, flow rates of 4GPM were obtained. this was using a 1/8" orifice.

Estimated airflow would be between 400 and 600CFM without any fans etc...

One of my friends recorded a video which follows, we do have a better one that someone else took, but its not available to me at the moment.

My cooling system consists of the following parts connected in this order

1: High head pump (115' head, 650GPH))

2: Wort chiller (I used an immersion chiller but a counterflow or other isolated chiller would work as well)

3: Spray head (constructed out of PVC, 1/8" hole with flat surface to disperse water, I used a 14 Ga. copper wire)

4: Spray Column (used some circular duct from an old furnace install)

5: Reservoir (An old trash can in my case, I cleaned it, but it doesn't really matter)

The idea is to pump the water through the chiller and disperse it into a fine mist while moving massive amounts of air to evaporate as much water as possible. Each pond of water evaporated removes about 1000 BTU from the environment in the form of a temperature drop. With evaporative cooling, it is possible to cool the working fluid down to the dew point so that means you can cool below the outside temperature which can be very significant in dry climates.

I have some pics of the rig following

(if you don't see the facebook pics ill load them up somewhere else)

The rig worked very well, however it should be noted that we were working in 20 degree weather. We were able to cool 5 gallons of beer from 180 to 80 in about 6 minutes which is on par with what I was able to achieve with straight well water. We did have a failure in the system as one of the hoses obtained from the trash essentially burst in use but lasted long enough for some results.

Some other relevant info:

With the mist nozzle on, flow rates of 4GPM were obtained. this was using a 1/8" orifice.

Estimated airflow would be between 400 and 600CFM without any fans etc...

One of my friends recorded a video which follows, we do have a better one that someone else took, but its not available to me at the moment.

Last edited by a moderator: