^^^^^ totally awesome.....i love the paint job and then how neat and tidy it is inside the panel. Great job

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show us your panel

- Thread starter Jps101

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

rockinmarty

Big Member

Nice paint job, looks realisticJust finished wiring and painting this.

Just finished wiring and painting this.

Very nice, how did you paint it?

bellinmi88

Well-Known Member

looks good, I like the box, you could mount that to the rig

curious how the inside looks though, what were you able to cram into there?

That's another story, it will be real tight!!! I plan on starting that next week, i add some updated photos. Here is the rig it will mount too.

Here is my humble panel.

120V 2000W, I have to give a big thanks to stlbeer for helping me get it done right. And, it works!

120V 2000W, I have to give a big thanks to stlbeer for helping me get it done right. And, it works!

ryane

Well-Known Member

just finished up a couple weeks ago myself, I did a couple things differently than most Ive seen

1 - the timer kills power to boil element if that is set on one of the switches

2 - the gfci breaker is in the control box

1 - the timer kills power to boil element if that is set on one of the switches

2 - the gfci breaker is in the control box

What kind of PIDs are those?just finished up a couple weeks ago myself, I did a couple things differently than most Ive seen

1 - the timer kills power to boil element if that is set on one of the switches

2 - the gfci breaker is in the control box

slakwhere

Well-Known Member

spare fuses taped to the inside of the control panel door. you, sir, are my hero

bellinmi88

Well-Known Member

johnp said:I'm going to need to know where you got that case.

Www.automationdirect.com

It is called a Control consolet

http://www.automationdirect.com/adc...onsoles_-a-_Consolets/WC-C_Operator_Consolets

ryane

Well-Known Member

What kind of PIDs are those?

Yah kinda tough to see in the pic, for whatever reason it uploaded kinda lousy

Anyway, the PID's are Watlows

kal

Well-Known Member

Interesting to see how control panels have changed over the last 4-5 years.

I started the same thread back in 2008 right here:

https://www.homebrewtalk.com/f11/show-us-your-control-panel-95301/

If you want a blast from the past, took a look at some of those panels.

Kal

I started the same thread back in 2008 right here:

https://www.homebrewtalk.com/f11/show-us-your-control-panel-95301/

If you want a blast from the past, took a look at some of those panels.

Kal

slakwhere

Well-Known Member

in that thread, kal thanked everyone for their inspiration in his "new" panel. now he's the defacto standard for panels. funny!

ryane

Well-Known Member

spare fuses taped to the inside of the control panel door. you, sir, are my hero

Ha, I thought it never hurts to be prepared, eventually Id like to have a small pocket for them, but haven't really looked hard enough for something yet

naamanf

Active Member

My less than exciting panel.

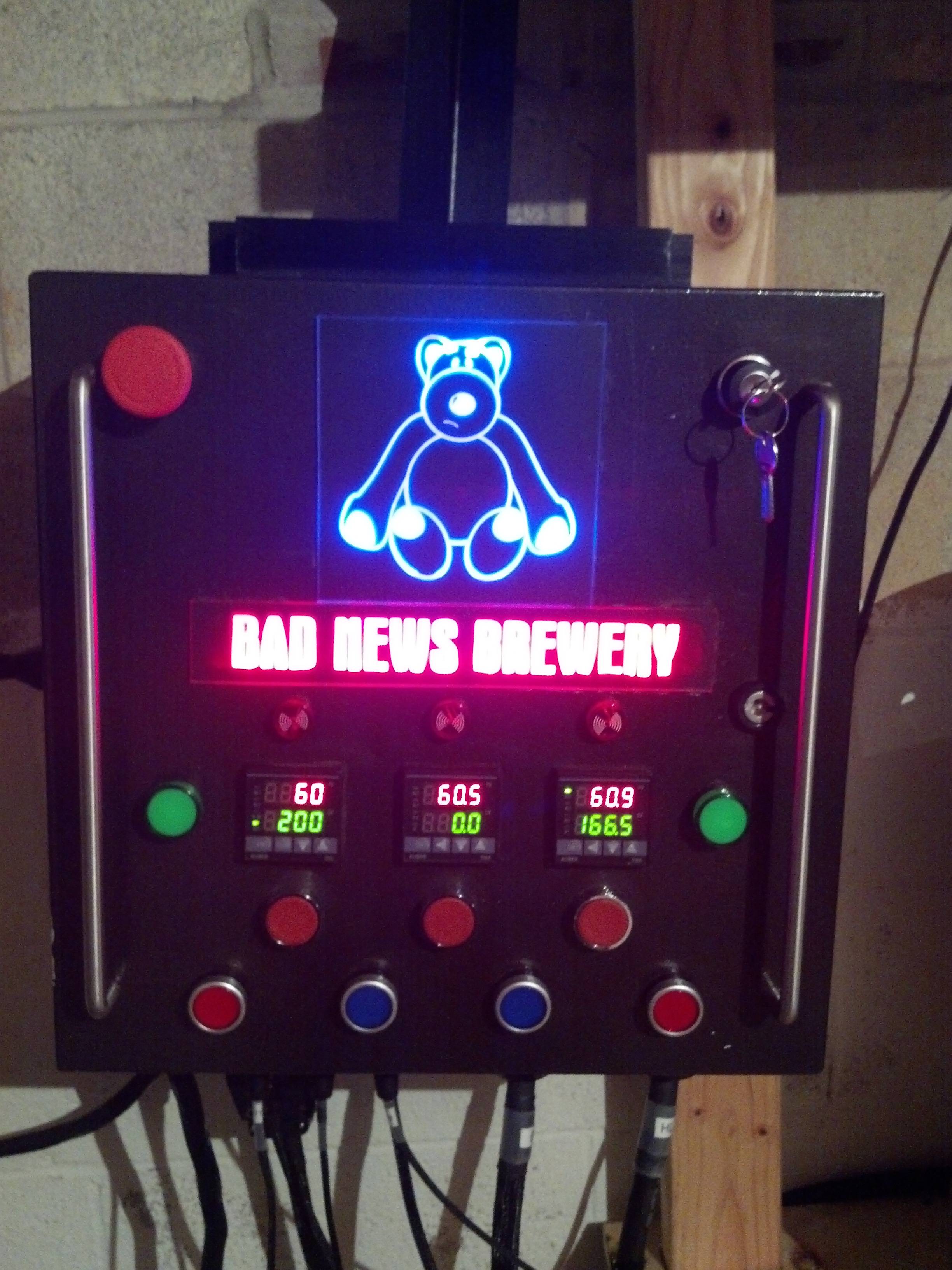

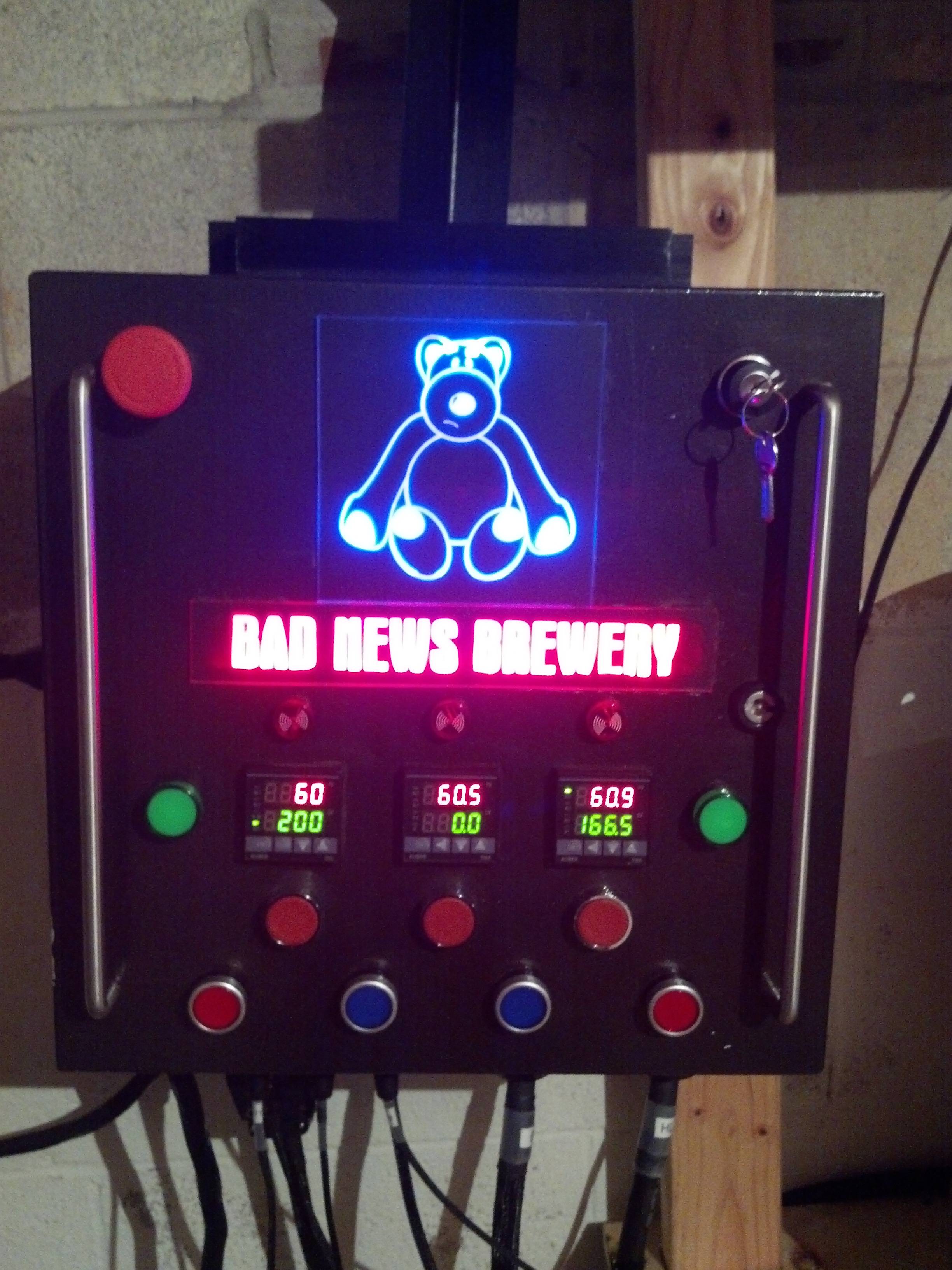

BadNewsBrewery

Well-Known Member

Here's mine. Everything is tuned up and running!

Bad news

your lit up logo on the control panel is way cool looking. What technology is that and where did you get it made?

your lit up logo on the control panel is way cool looking. What technology is that and where did you get it made?

BadNewsBrewery

Well-Known Member

It uses a combination of lasers, holographic panels, and virtual reality.

Wait. No. It was actually much easier than that, and I made it all myself. Here's the basic write-up.

I can answer any questions you have on that thread, to keep from stalling this one.

Wait. No. It was actually much easier than that, and I made it all myself. Here's the basic write-up.

I can answer any questions you have on that thread, to keep from stalling this one.

BadNewsBrewery

Well-Known Member

Yes indeed - a few coats of black BBQ paint. Didn't have the patience for polishing. PM me for some lessons learned.

TheFlyingBeer

Well-Known Member

Here is my panel, I am better at engineering than I am at taking pictures:

And the inside, some wires need to be straightened out once development is done:

Details and build progress are here.

Hardware build is 95% complete, just software remaining.

And the inside, some wires need to be straightened out once development is done:

Details and build progress are here.

Hardware build is 95% complete, just software remaining.

movet22

Well-Known Member

Here is my panel, I am better at engineering than I am at taking pictures:

And the inside, some wires need to be straightened out once development is done:

Details and build progress are here.

Hardware build is 95% complete, just software remaining.

I may never see anything more amazing in my entire life...

You, sir, are impressive! :rockin:

at3brew9

Member

Newly revamped panel for indoor brewing. PLC based using a Siemens S7-200 controller with DC input/output, 4-channel t/c, and 2-channel RTD modules, along with OP7 HMI. Also features Omega water meter for accurate filling and two 240VAC and two 120VAC receptacles controlled by SSRs for heating elements & heatsticks.

alien

Well-Known Member

Very cool builds on this thread.

BadNewsBrewery

Well-Known Member

Also features Omega water meter for accurate filling...

Do you have a link to more information on this and how you tied it all in?

-TH-

Well-Known Member

Here's my simple PWM control panel:

TheFlyingBeer

Well-Known Member

Here's my simple PWM control panel:

Very clean, looks awesome with the custom decals!

jeffmeh

Well-Known Member

- Joined

- Feb 26, 2009

- Messages

- 2,145

- Reaction score

- 216

Here's my simple PWM control panel:

Looks great, although I would have gone with a PWM that went up to 11.

Jps101

Well-Known Member

Very cool...ditto on "going to 11"

at3brew9

Member

Do you have a link to more information on this and how you tied it all in?

Bought the 1/2" pulse meter several years ago from Omega (they've gone up a lot since then):

http://www.omega.com/pptst/FTB4600.html

Paired it with a 1/2" solenoid valve from ebay. Wired the signal input to the PLC and used it to drive a counter. The meter gives 151.4 pulses/gallon--just enter the # of gallons desired, calculate how many pulses that is, set the counter and turn on the solenoid valve. Turns off automatically when count is reached. I usually have it do a 1/2 gallon priming fill or so when the filter is dry. After that, it's pretty accurate--just hook up a hose with a U-shaped wand that I can hang over the side of the HLT or MLT and filling is a breeze.

Really any counter would work (Omega sells one)--you'd just have to do the math yourself to set the counter preset. I used to use an Allen-Bradley smart relay (Pico) for that purpose and other controls on my previous system.

-TH-

Well-Known Member

Looks great, although I would have gone with a PWM that went up to 11.

Brilliant! How did I not think of that.

Newly revamped panel for indoor brewing. PLC based using a Siemens S7-200 controller with DC input/output, 4-channel t/c, and 2-channel RTD modules, along with OP7 HMI. Also features Omega water meter for accurate filling and two 240VAC and two 120VAC receptacles controlled by SSRs for heating elements & heatsticks.

I have no idea what you just said, but looks impressive.

Huaco

Well-Known Member

I'm sure most of you have seen Kal's design... I built the 50 Amp Back to Back panel. Waterjet cut the panel door openings. Spent about two weeks in the evenings after work wiring it all up... one circuit at a time! Built in a 16x20 enclosure.

ReuFroman

Well-Known Member

Just finished wiring and painting this.

That is amazing.

I was thinking about wrapping my panel with a vinyl but pain is great!

I think my next panel will look very steampunk. Have analog meters to measure power output and temp with a bcs brain. I have a single project I keep thinking about that it might work perfect for.

OatStraw

Well-Known Member

This is my plan for my eHLT/BIAB setup, taken from Auber's website. Has the layout I want, except I'll be adding an e-stop. I'm expecting to make control panel purchases over the next two paydays.

WOW this looks exactly like what I want to build. Are there plans and part list anywhere? I tried to search Aubers site for a description of this build but didn't find anything.

SookeBrewing

Well-Known Member

rgauthier20420

Well-Known Member

- Joined

- Sep 20, 2012

- Messages

- 771

- Reaction score

- 70

Is there anyone out there that has used a large microwaveable Tupperware container as an enclosure? I've got those lying around and could shave $40 on my build costs with it. My thought is it could handle the heat seeing as it's microwaveable and holds food being heated to temps quite high.

Let me know your thoughts.

BTW, these builds are pretty amazing!

Let me know your thoughts.

BTW, these builds are pretty amazing!

kal

Well-Known Member

I wouldn't use Tupperware. It's not as rigid, melts easier, etc.

Kal

Kal

ReuFroman

Well-Known Member

kal said:i wouldn't use tupperware. It's not as rigid, melts easier, etc. Kal

+1

ReuFroman

Well-Known Member

Holy cow how did I miss the see thru box. Awesome!

Similar threads

- Replies

- 10

- Views

- 668

- Replies

- 2

- Views

- 669

- Replies

- 4

- Views

- 171