bstacy1974

Well-Known Member

is driving me crazy. I'm only two brews in to homebrewing. First brew turned out great, IMO. It was a Mild partial mash. 4.5lbs of grain with 1.5lbs of extract added late in the boil. I was aiming for a mash temp of 155F , but underestimated how much the temp would drop with the 50F grain. Ended up mashing at 150F. No big deal, right.

So, Saturday night, I brewed an Amber recipe I created with Brewtarget, using some other amber recipes as a guide. 8lbs of grain, 1.8lbs of extract, late addition in boil.

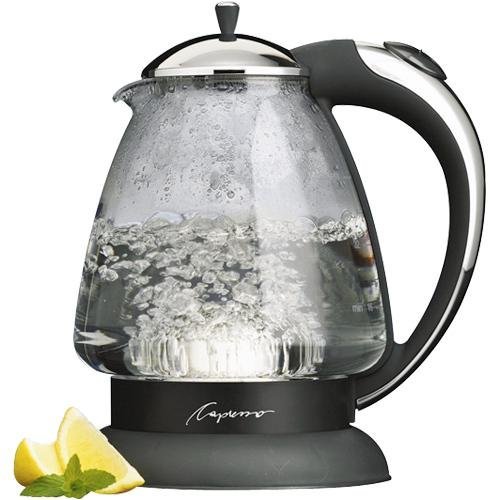

This time, I actually looked up strike water estimated temp, 168.9F. Strike water was right between 168 and 170 on my thermometer. I poured the water into the mash tun, checked the temp....162F!!! I rolled with it.

Now, I'm worried that my beer is ruined. I do have fermentation (S-05), but is my beer going to be too sweet because of the high temp?

So, Saturday night, I brewed an Amber recipe I created with Brewtarget, using some other amber recipes as a guide. 8lbs of grain, 1.8lbs of extract, late addition in boil.

This time, I actually looked up strike water estimated temp, 168.9F. Strike water was right between 168 and 170 on my thermometer. I poured the water into the mash tun, checked the temp....162F!!! I rolled with it.

Now, I'm worried that my beer is ruined. I do have fermentation (S-05), but is my beer going to be too sweet because of the high temp?