Has anyone built one of these? I have a PWM on the boil kettle and am looking to try something new for giggles.

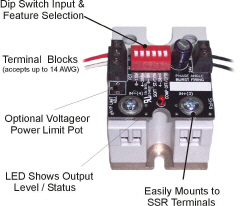

I found this unit online. http://www.nuwaveproducts.com/ssrman-1p.htm

I was thinking of wiring that into a box with a random SSR and see how that compares to the PWM that I have.

If no one has done it no big deal, but was wondering if anyone had any experience?

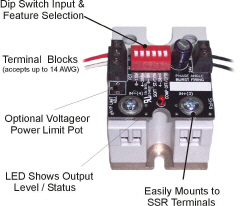

I found this unit online. http://www.nuwaveproducts.com/ssrman-1p.htm

I was thinking of wiring that into a box with a random SSR and see how that compares to the PWM that I have.

If no one has done it no big deal, but was wondering if anyone had any experience?