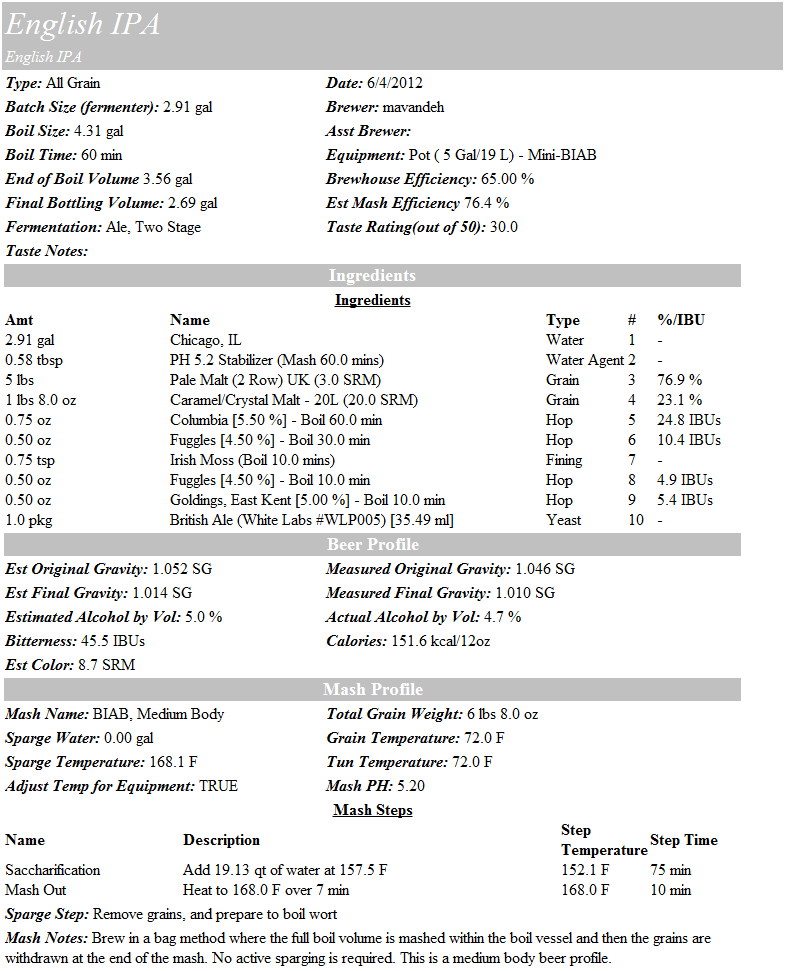

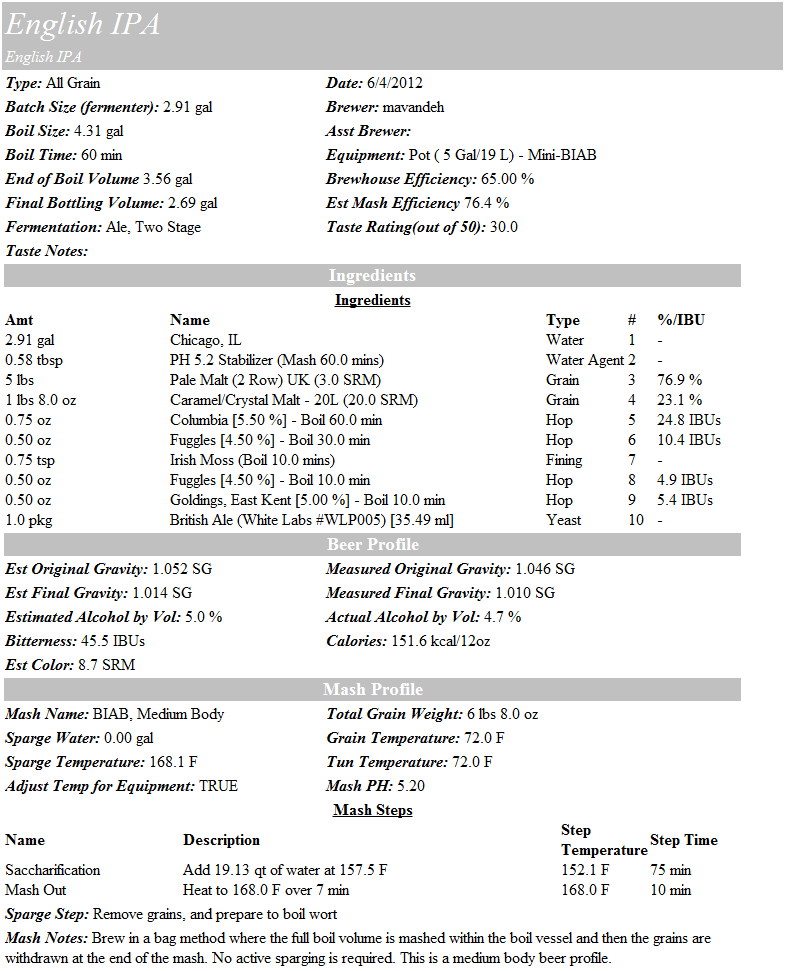

Yes, my advice still applies. See the strike temp of 157.5°? BS is calculating that based on water volume, grain volume and temp, and tun temp. For both grain and tun temp, your settings show 72, and BS is using this info to come up with the 157.5 strike temp in order to end up at 152 after dough-in. However, your tun will not be 72 at dough-in, it'll be whatever the water temp is, which should be about 155.

If you go into the mash settings in BS and change the tun temp from 72 to 155, you will see the strike temp drop a degree or two. Then, change your tun temp again to match the new strike temp exactly so the two temps are same-same. My experience with similar size grain bills is that the strike temp should be about 155.0-156. Overshooting by 2 degrees may not seem like much, but it will make a difference in the amount of fermentable/unfermentable sugars that get converted, and therefore FG, so it pays to try to get as close as possible to your intended mash temp. Making this easy to overlook setting correct will help with that.

Also, I see in your brew steps that there is a step for mash out at 168. Lot's of BIAB'ers skip this, but I would suggest that you do it. I firmly believe that it helps improve efficiency. For most recipes, there's no reason why you shouldn't be able to hit 80% mash efficiency every time if you do the mash out.

One more thing: prior to dough-in, as you approach strike temp, make sure you stir the mash water well while it's heating to keep the temps even throughout. It's easy to be several degrees warmer near the bottom of the BK than what your thermo is reading near the top. Stirring well will help to minimize temp stratification so you get accurate temp readings. I usually dial the flame back a little when I get within a few degrees of strike temp so I have better control of how fast the temp is rising.