blackheart

Well-Known Member

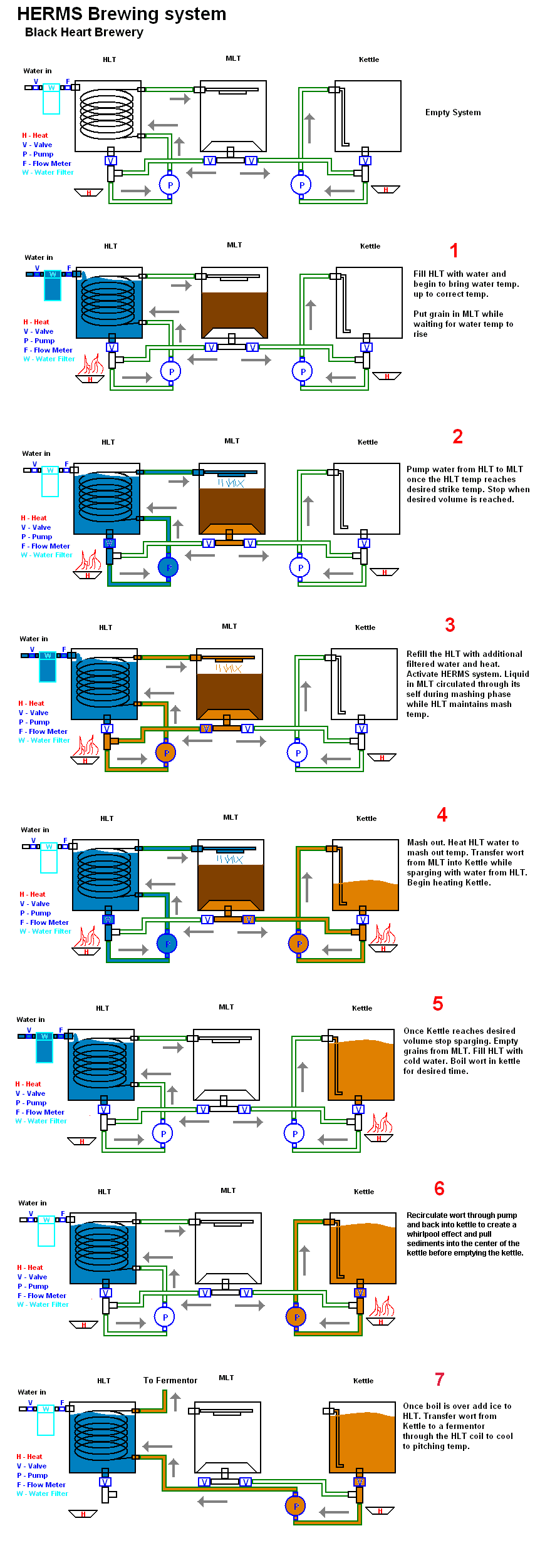

We are attempting to construct a new brewing system now that our small home brewery is nearly complete. I started a new thread for this HERMS system but it is a continuation of this older thread when we were considering RIMS.

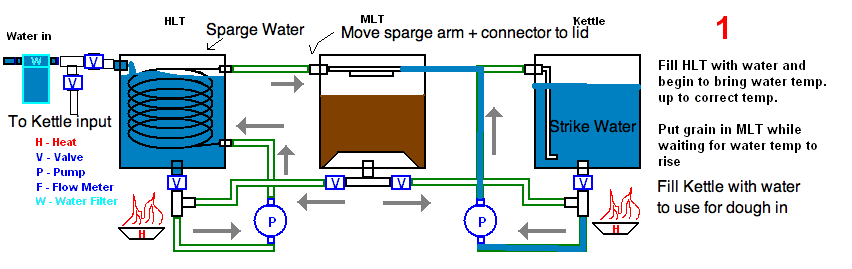

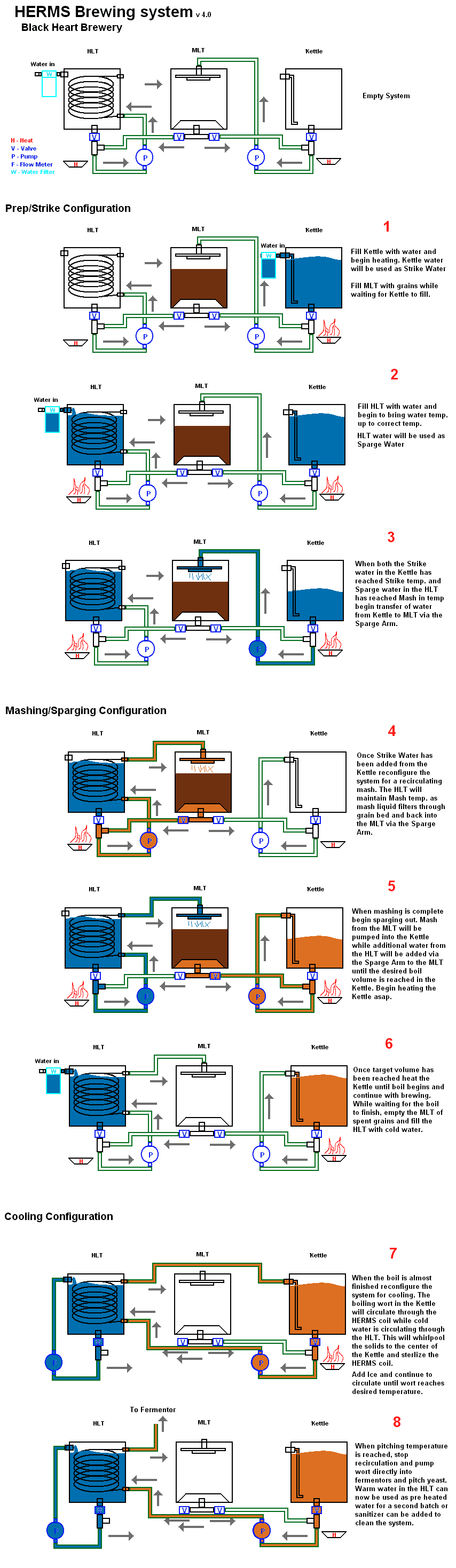

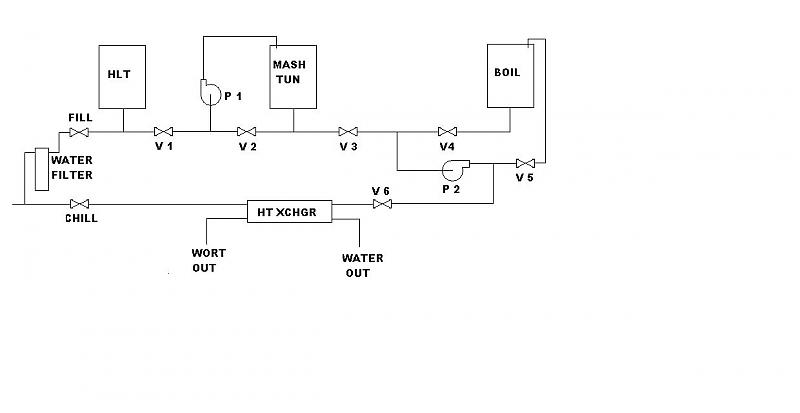

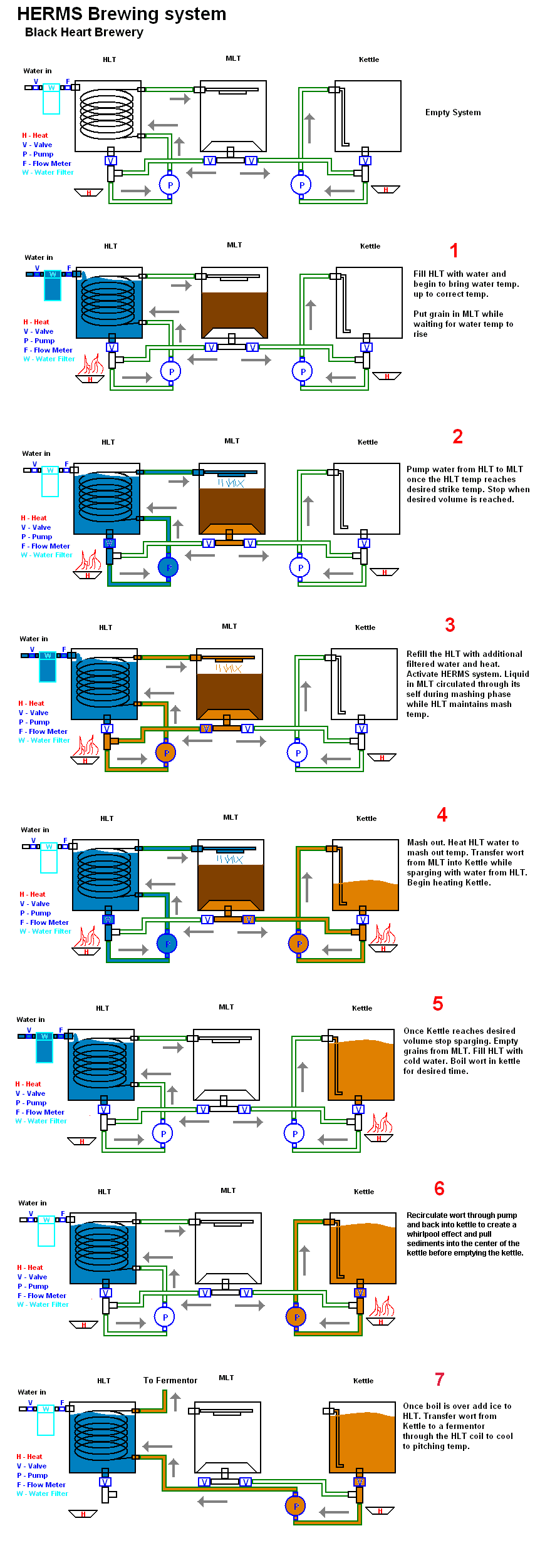

Anyway here is the outline of how the system will operate.

We are working on figuring out each and every part we will need to order. Here is an example of one of the parts assembly pictures we are working on. This would be the bottom valve on the HLT and Kettle from the image above. Everything is 1/2" MPT

Kind of guessing on build our own bulk heads there. Compression fitting inside let us connect to SS tubing to make a dip tube or to connect to a coil etc. The threaded pipe is a 1" piece of 1/2" MPT I assume it needs a washer and O-ring on either side with a nut on the outside and a compression fitting on the inside. Hopefully there is enough thredding left over to thread it onto the valve. This would be a 12v 1/2" SS electronic valve that can handle 200+F

We are looking for some feedback/suggestions/comments on this system so we can make any final revisions before placing orders. Thanks!

Anyway here is the outline of how the system will operate.

We are working on figuring out each and every part we will need to order. Here is an example of one of the parts assembly pictures we are working on. This would be the bottom valve on the HLT and Kettle from the image above. Everything is 1/2" MPT

Kind of guessing on build our own bulk heads there. Compression fitting inside let us connect to SS tubing to make a dip tube or to connect to a coil etc. The threaded pipe is a 1" piece of 1/2" MPT I assume it needs a washer and O-ring on either side with a nut on the outside and a compression fitting on the inside. Hopefully there is enough thredding left over to thread it onto the valve. This would be a 12v 1/2" SS electronic valve that can handle 200+F

We are looking for some feedback/suggestions/comments on this system so we can make any final revisions before placing orders. Thanks!