killsurfcity

Well-Known Member

- Joined

- Feb 11, 2009

- Messages

- 170

- Reaction score

- 18

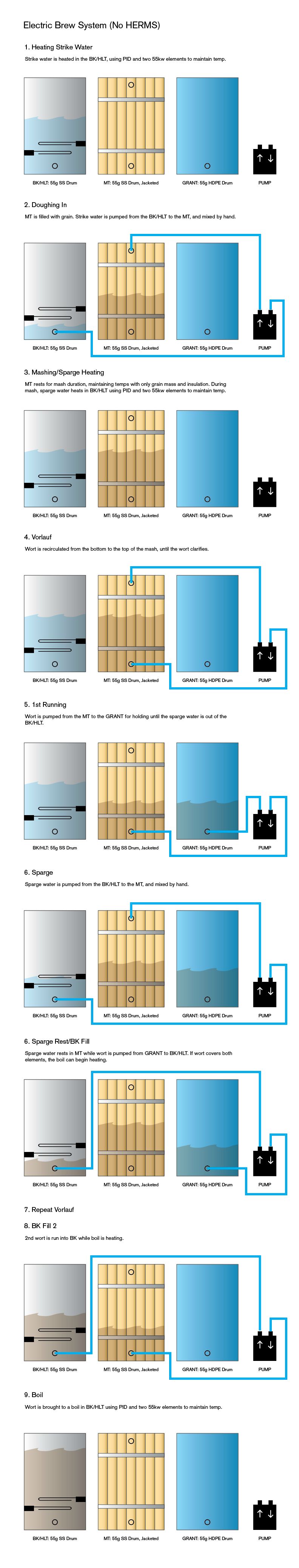

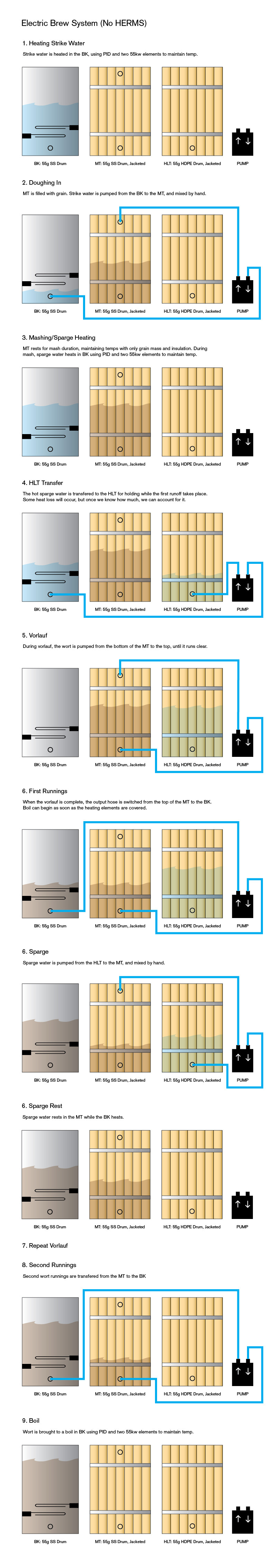

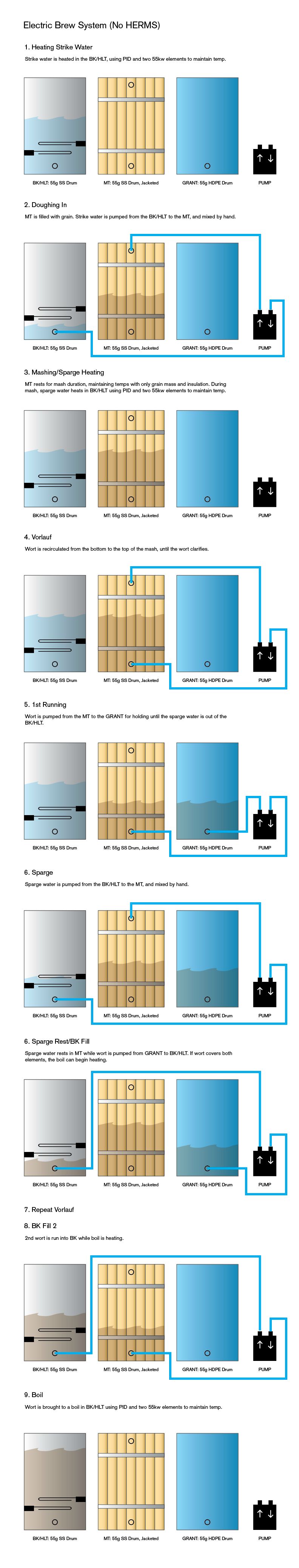

Some friends of mine and I are partnering together on a 1-1.5bbl system. The budget is not huge, but I think we can pull it off if we make some smart choices.

One thing I read a lot is that jacketing the mash nearly eliminates the need for HERMS to keep temp in a single infusion mash. So I decided to design my system without RIMS or HERMS, and with only a single pump. This helps us to start on the cheaper end, but we can always add the HERMS coil and control later.

Thus far I have not seen anyone doing this, so I have a couple questions about the control panel setup.

With the configuration below, only the BK/HLT will have elements/probe(s). The mash will just use a standard dial thermometer. Or is there a way to incorporate some kind of temp readout for the mash into the panel?

With two elements, I've heard it's better if one fires full on, and the other is controlled. This way only one will be switching on and off, and you only need one probe. If this is true, how do you set the "full on" element up? Switch + pot? Naturally, I'd want a switch for my pump in the panel as well.

Other than that, what do you think of this method? Sorry for the really long image. I wanted to draw it all out just to make sure I wasn't missing anything. Thanks!

One thing I read a lot is that jacketing the mash nearly eliminates the need for HERMS to keep temp in a single infusion mash. So I decided to design my system without RIMS or HERMS, and with only a single pump. This helps us to start on the cheaper end, but we can always add the HERMS coil and control later.

Thus far I have not seen anyone doing this, so I have a couple questions about the control panel setup.

With the configuration below, only the BK/HLT will have elements/probe(s). The mash will just use a standard dial thermometer. Or is there a way to incorporate some kind of temp readout for the mash into the panel?

With two elements, I've heard it's better if one fires full on, and the other is controlled. This way only one will be switching on and off, and you only need one probe. If this is true, how do you set the "full on" element up? Switch + pot? Naturally, I'd want a switch for my pump in the panel as well.

Other than that, what do you think of this method? Sorry for the really long image. I wanted to draw it all out just to make sure I wasn't missing anything. Thanks!