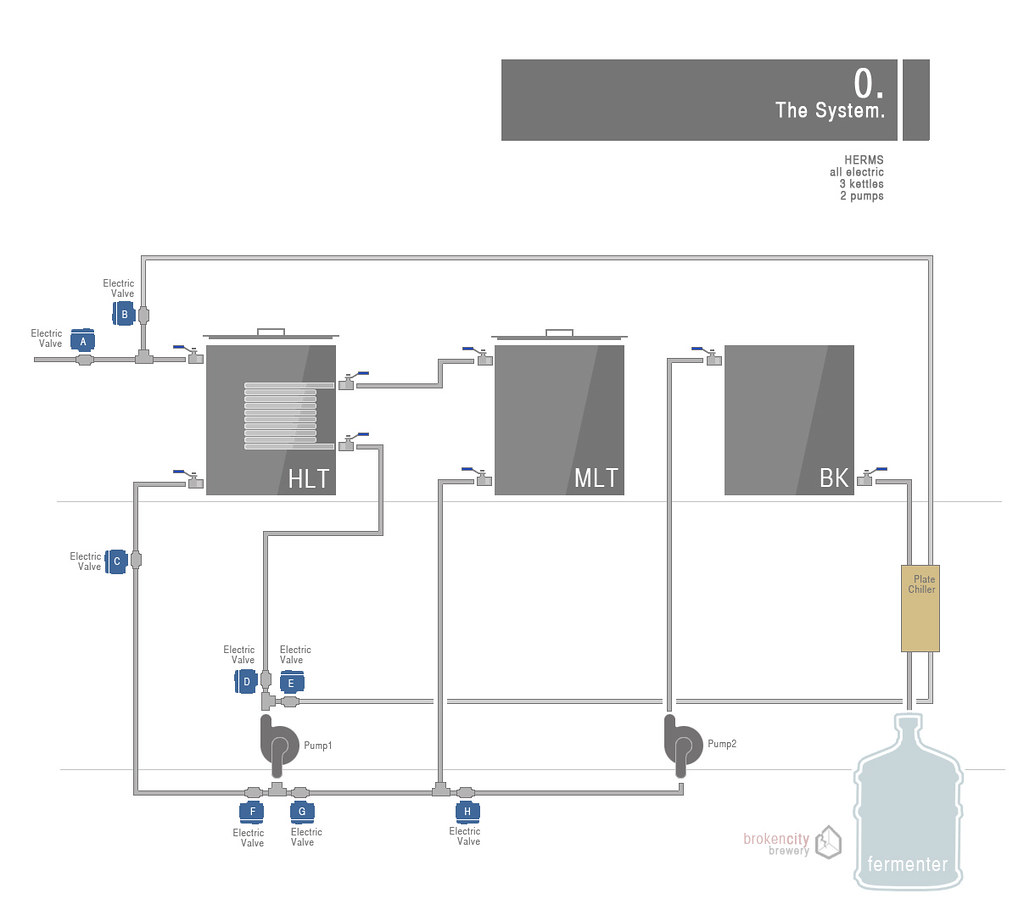

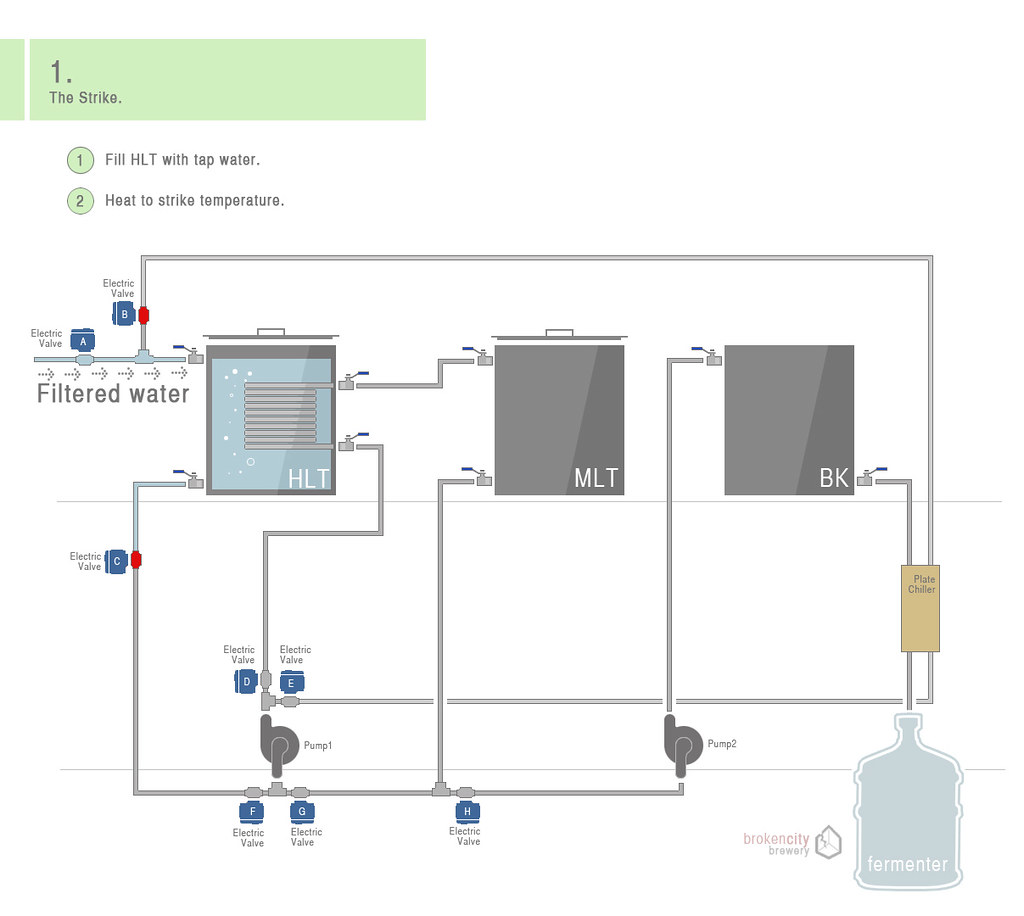

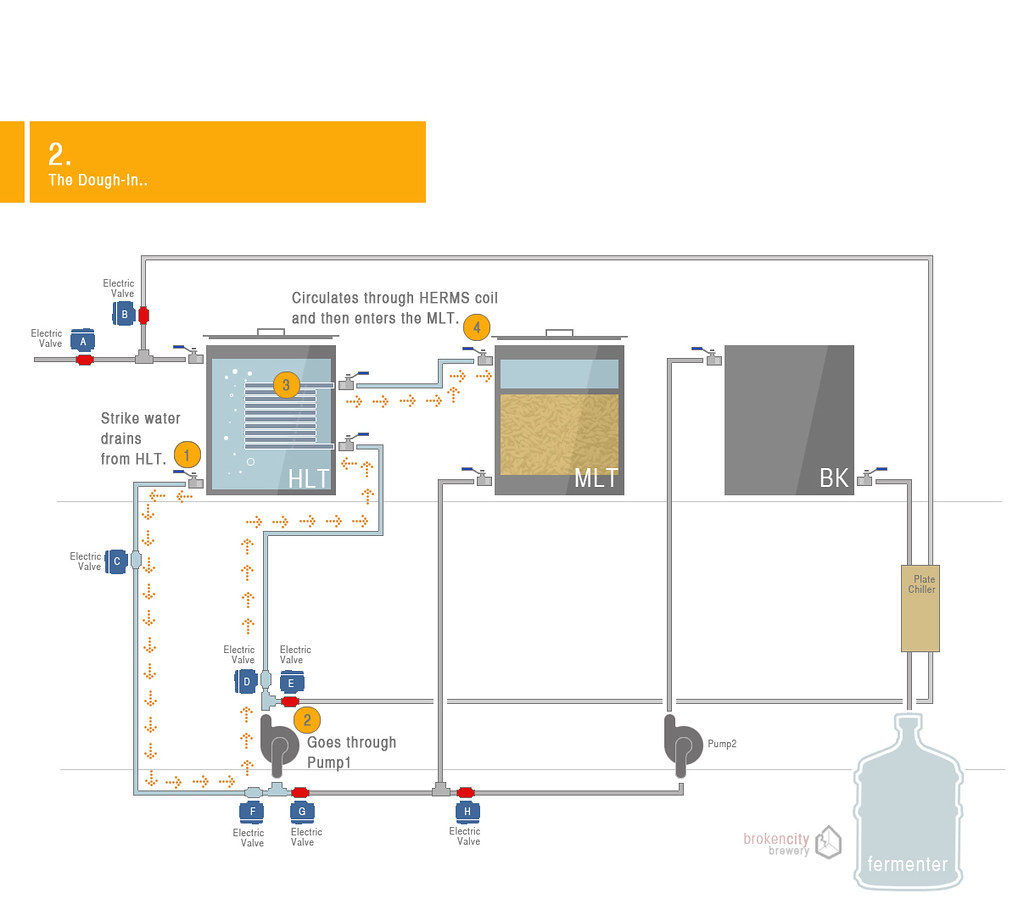

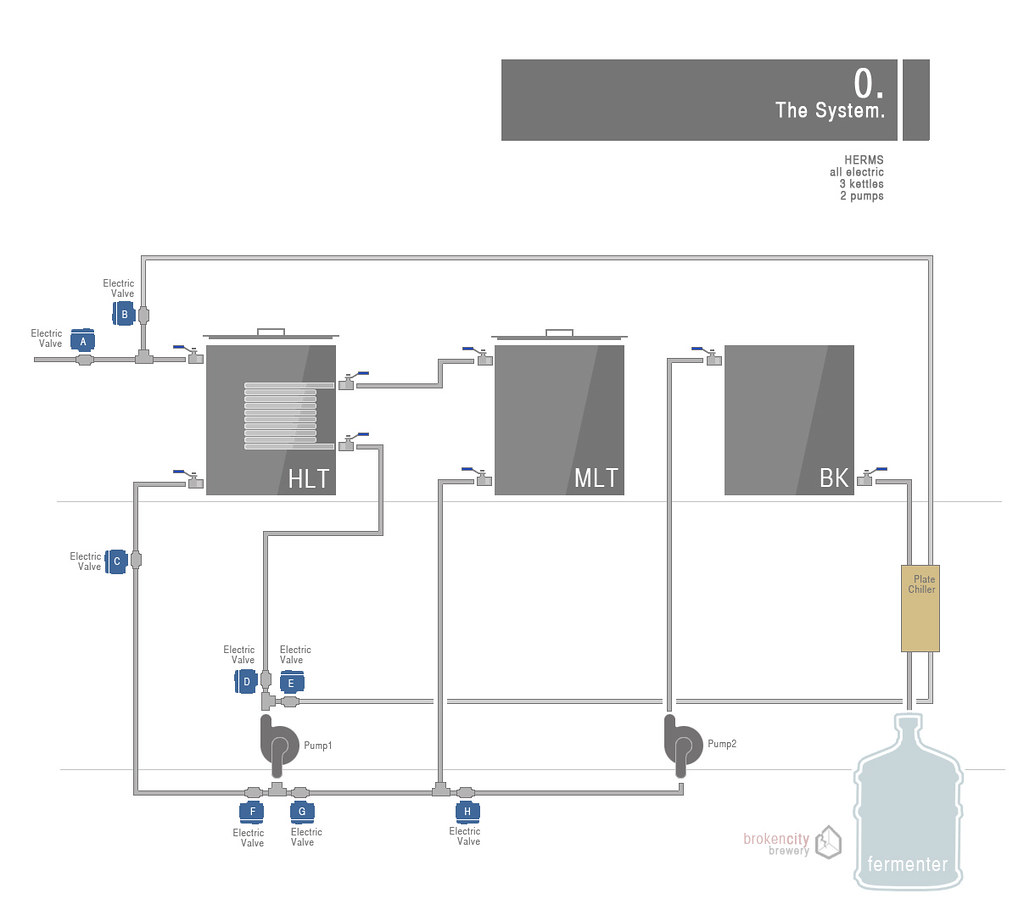

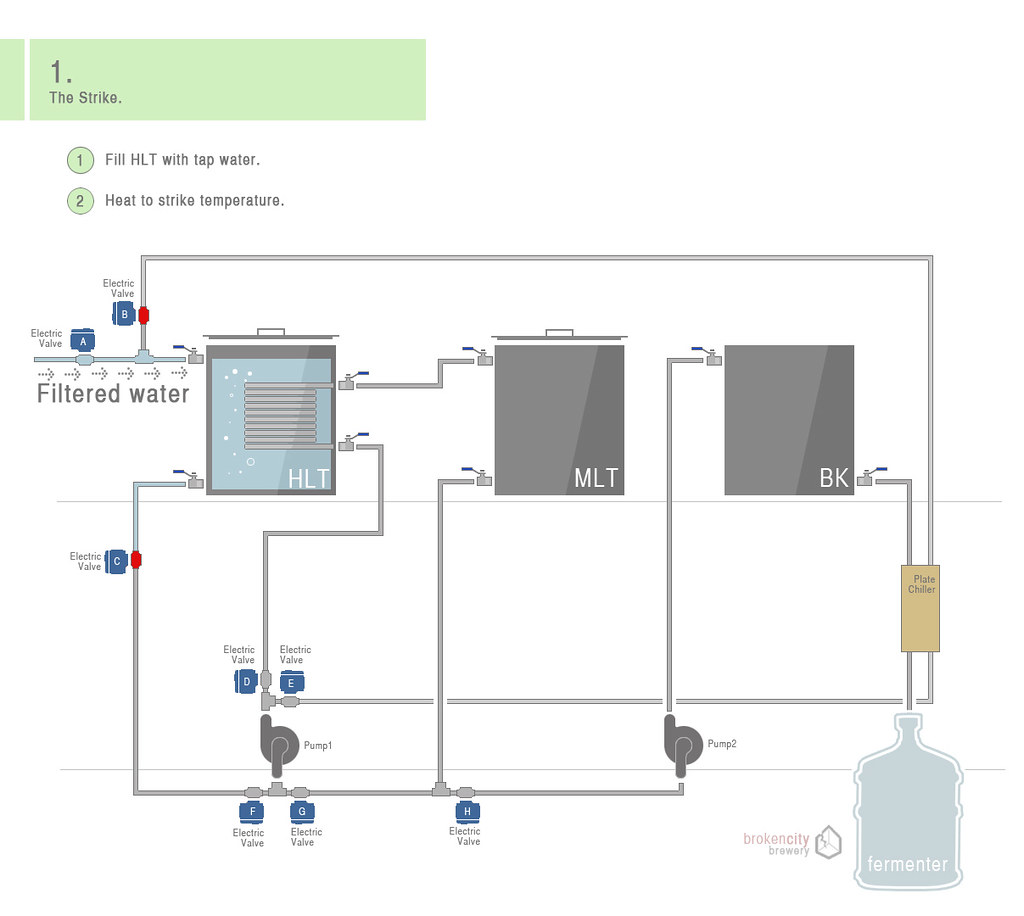

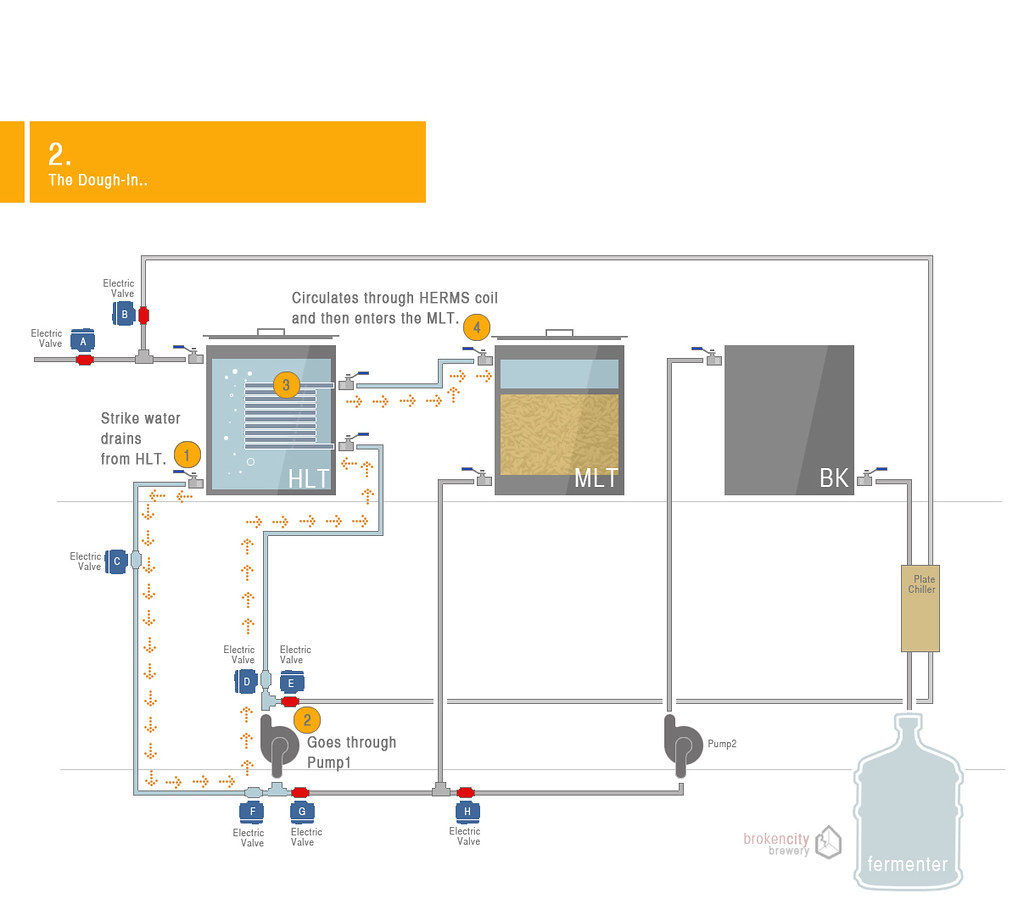

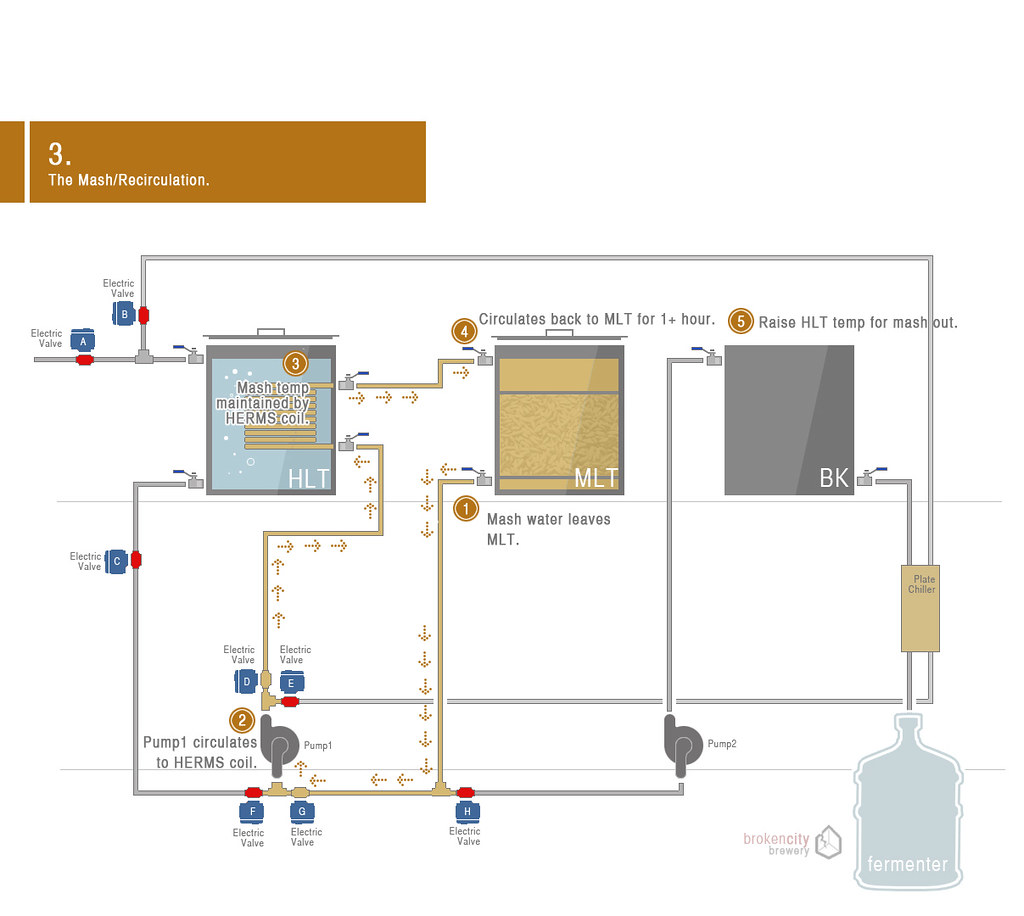

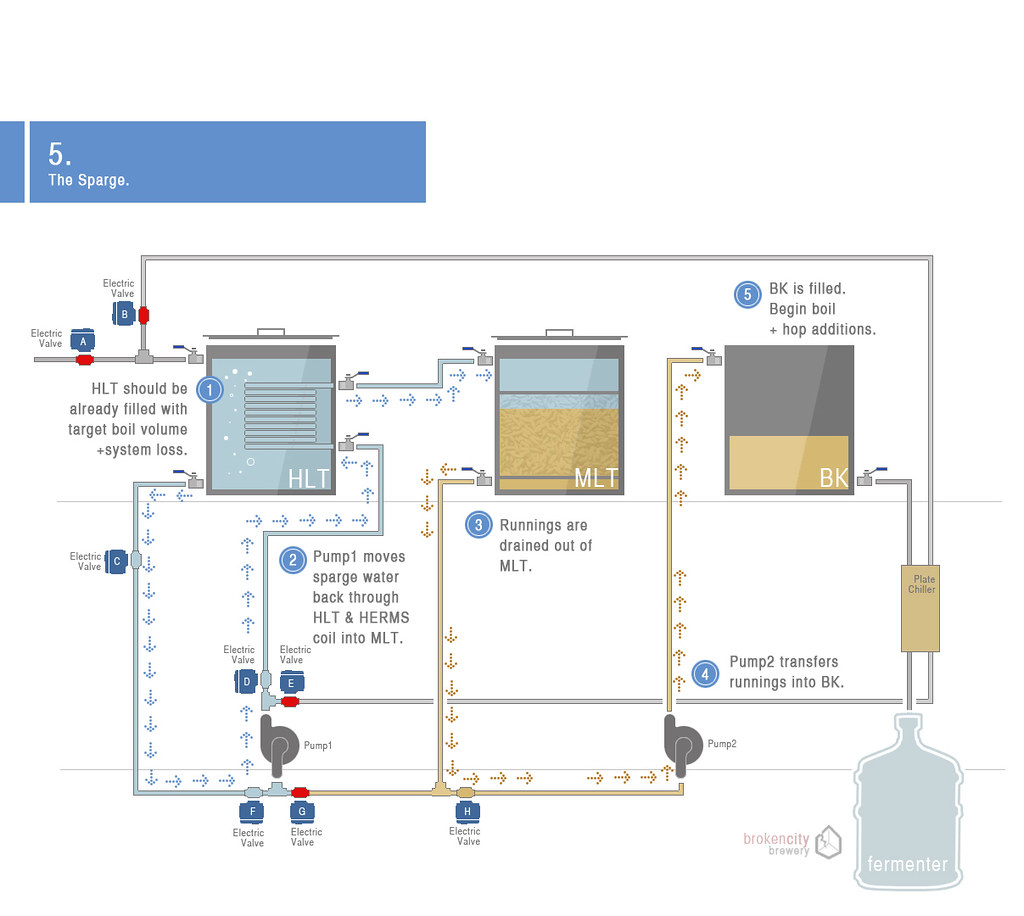

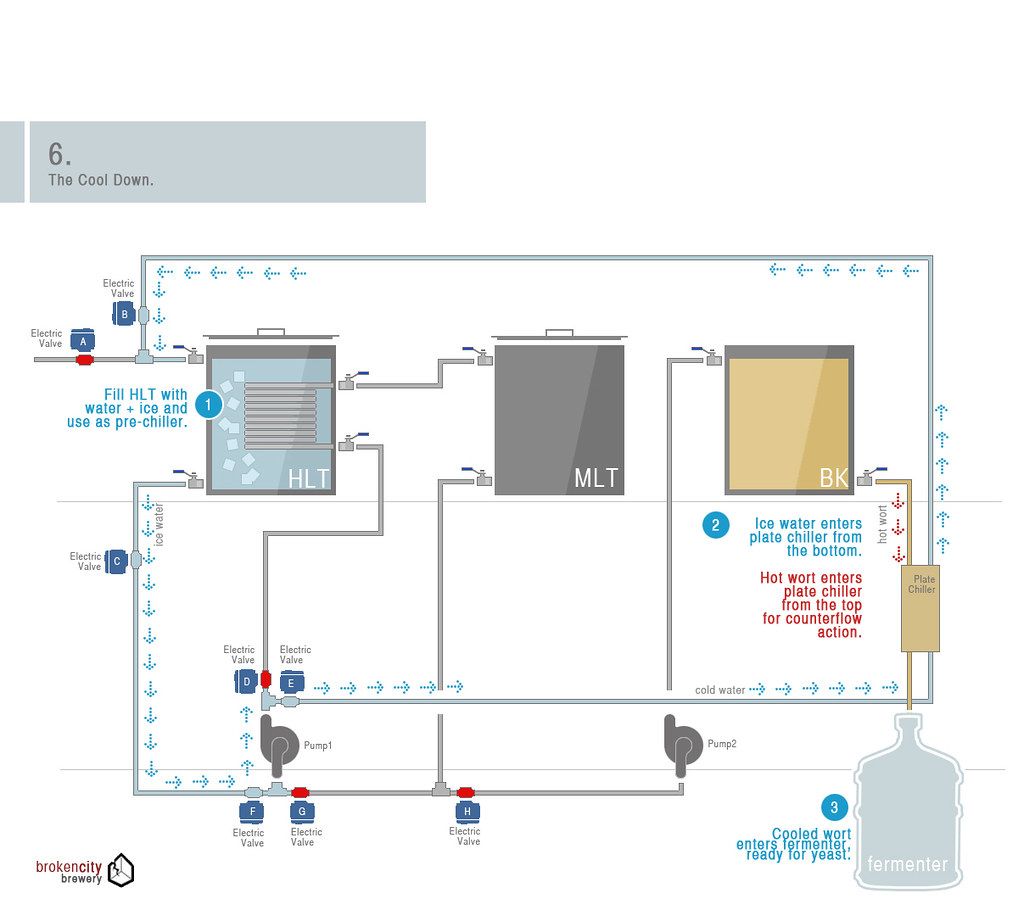

@BigJay13 Hey Jay, thanks for the reply. I am slow responding back (holidays). Yeah...you sort of nailed it on the head "Surprised you dont know what you want your process to be".... The quick back ground is i did several extract brews, enjoyed the process and wanted to go to the next stage. I was living just North of Seattle and had great access to a guy who, for a lack of a better term, stock piles home brew stuff and resells it (as well as customizes it) so I had access to (compared to retail) very inexpensive equipment. I was able to find a brew stand for cheaper than the cost of the steel let alone the time and welding, so it seemed "economical" to go into a single tier system. I read up a fair amount here on HBT and decided I wanted to try and make it a HERMS, but eliminate the complication that came with electronics (electric propane switches....didnt have 220V to do electric elements).

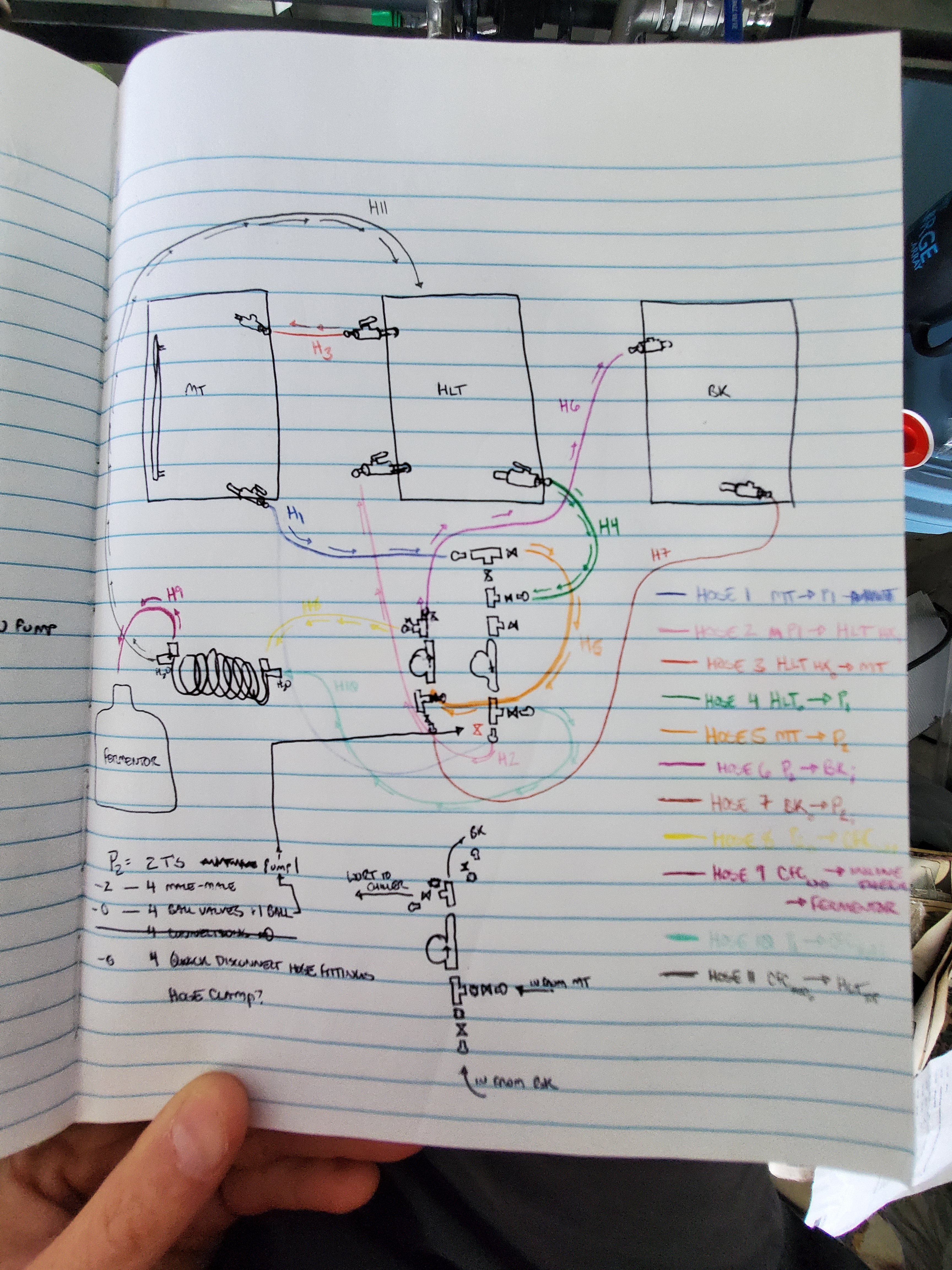

Saw this thread, liked how it was laid out, and thought "I can replicate this with what i have" and thats what i aimed to do. Then after acquiring everything and getting ready to assemble, my wife and I decided we should move back to the east coast closer to family and the brewing effort halted and we focused on prepping the house to put on the market and logistics for a cross country move.

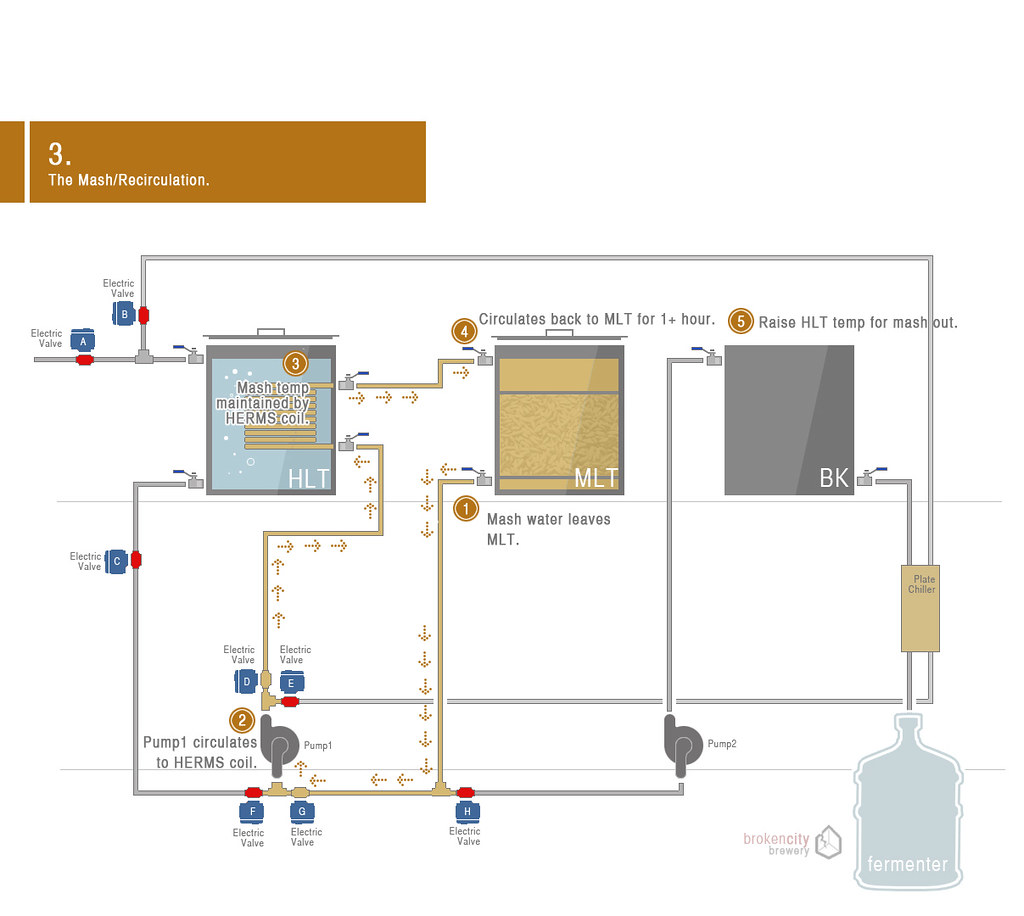

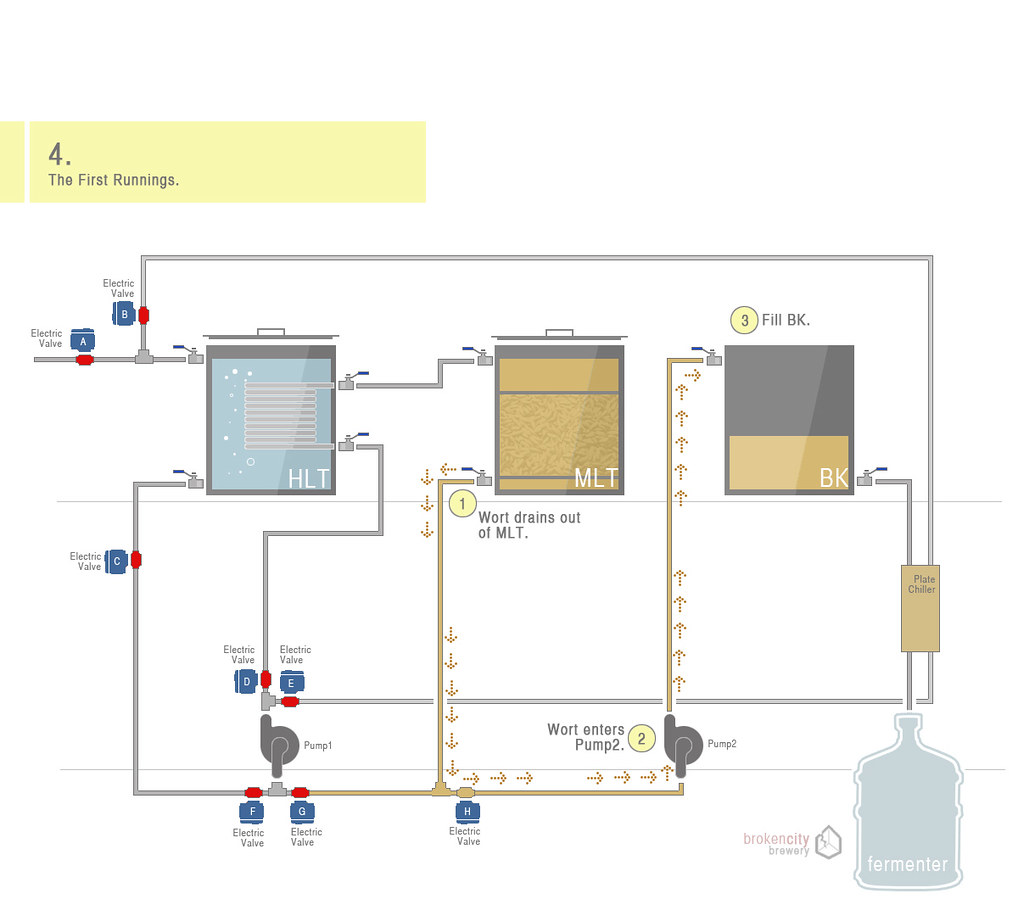

Now I am in the Charlottesville VA area, and I havent connected to the brewing community here yet, but I want to get a brew on this rig! Like I said in the post you replied to, I thought I knew what i was going to do for sparging, but I did some more reading and got myself to the spot where I said "crap, what do I do for sparging - my plan has been to spray/trickle water from above onto the grain as I pumped it out, but that certainly wont take an hour (I dont think)"

so thats where I am at, still havent brewed on it (decided the MT I have shown (far left) only could hold 11 gallons and I didnt think that would be large enough for the grain bill I have, so I got a local brewers keggle and just got it set up the way i wanted. So last step (before brewing) is to mark off my sight glasses and reclean the keggles.

So does fly sparging have to take 45 mins - hour? Cheers and Happy New Years y'all