OatStraw

Well-Known Member

OK I think I'm getting confused with 10/4 and 10/3 wire. Everything I've seen calls for 10/4 cabling from the source. Looking at what lowes sells as 10/3 comes with 4 wires including the ground.

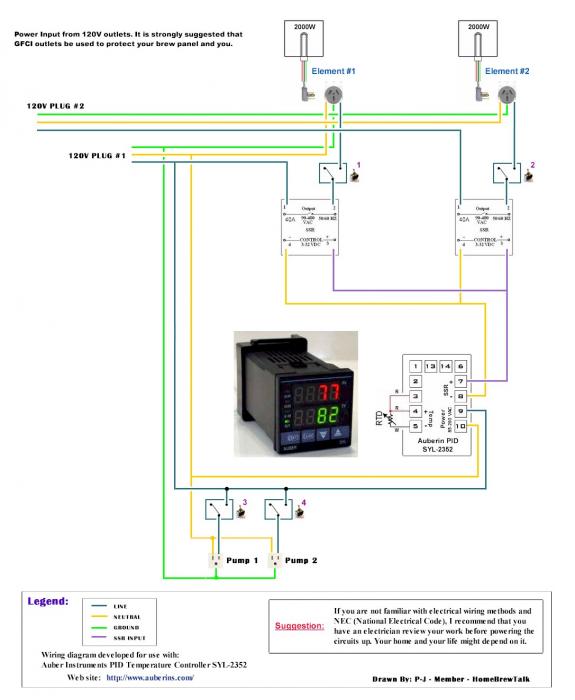

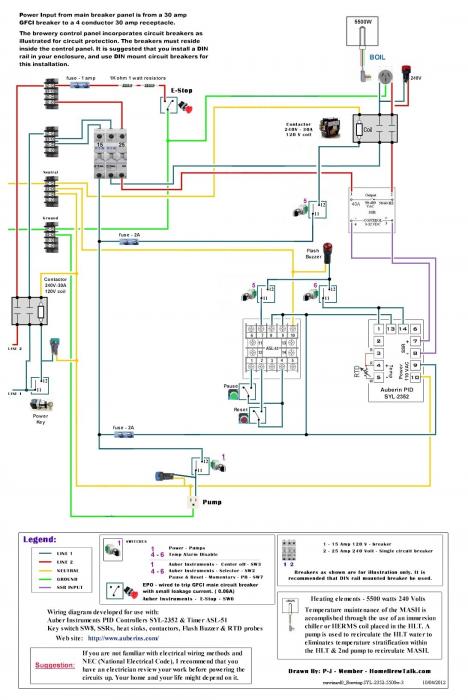

This diagram from ebrew supply shows only 3 wires, not sure where the ground is supposed to go.

http://www.ebrewsupply.com/designs/PID/30a-PID-1-2-1PID-Electric-BIAB.pdf

To be able to put a 120v outlet in for a pump will that lowes 10/3 wire work, and is the ebrewsupply.com diagram correct?

This diagram from ebrew supply shows only 3 wires, not sure where the ground is supposed to go.

http://www.ebrewsupply.com/designs/PID/30a-PID-1-2-1PID-Electric-BIAB.pdf

To be able to put a 120v outlet in for a pump will that lowes 10/3 wire work, and is the ebrewsupply.com diagram correct?