kal

Well-Known Member

I don't know if this sort of switch exists, it may be just me not using the right terminology when searching.

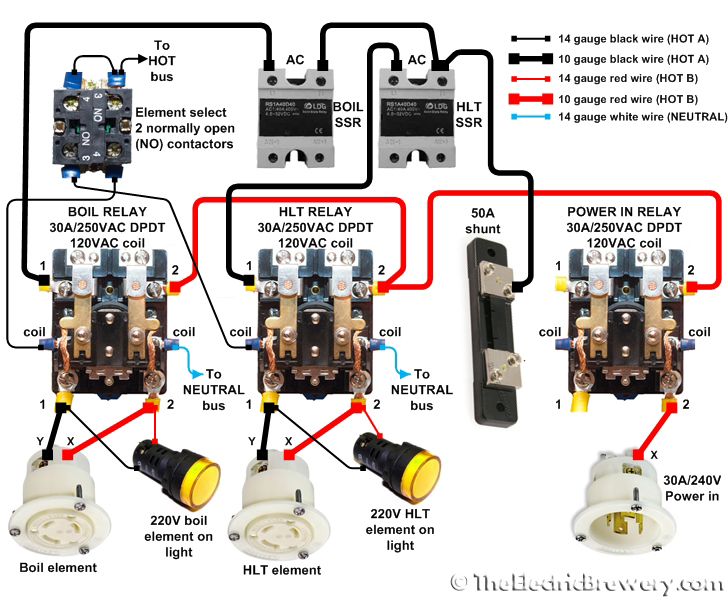

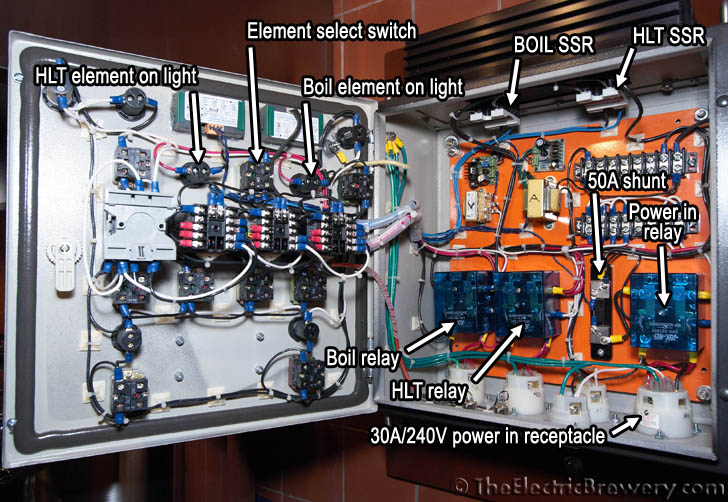

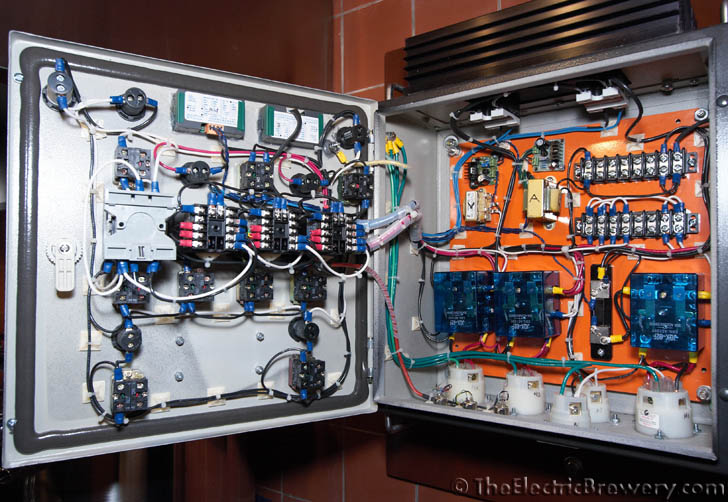

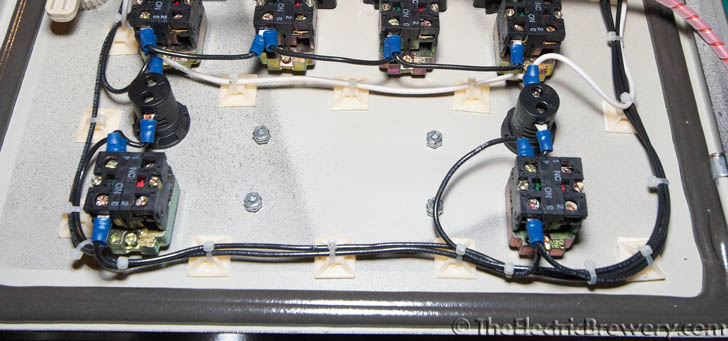

I have a 3-way maintained ELEMENT SELECT switch on my control panel today like this:

It's used to select which of the two elements (BOIL or HLT) receives power. In the center position both elements are off. This ensures that only one element may be on at once (a design choice I made).

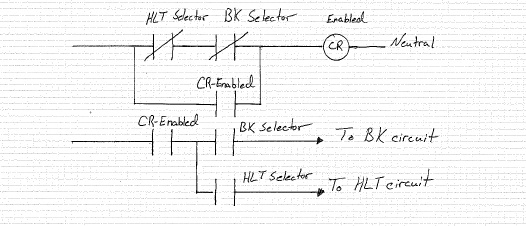

I'm looking for a 3 position maintained switch that springs back to center OFF position if power is cut.

In other words, the two outside maintained positions are somehow maintained but if power to the panel is cut, the switch instead behaves like a spring return switch and springs back to the center OFF position. I imagine to do this, when the switch is turned to either ON position it would have to energize some sort of holding (electromagnet?) circuit that holds the switch in the on position.

Why do I want this?

Today whenever I first turn on the panel power, I have to always *first* make sure that this switch is in the off position. While this is fine for my use, from an ergonomic/process standpoint that's not quite right: When power's cut to the panel, this switch should always reset itself to off for safety reasons. Some sort of interlock is required to make sure someone doesn't trip up. This would stop having an element turn on when then panel is first turned on. (Especially useful for someone who doesn't use ULWD elements which will pop if not turned on while in water).

Anyone heard of something like this?

Kal

I have a 3-way maintained ELEMENT SELECT switch on my control panel today like this:

It's used to select which of the two elements (BOIL or HLT) receives power. In the center position both elements are off. This ensures that only one element may be on at once (a design choice I made).

I'm looking for a 3 position maintained switch that springs back to center OFF position if power is cut.

In other words, the two outside maintained positions are somehow maintained but if power to the panel is cut, the switch instead behaves like a spring return switch and springs back to the center OFF position. I imagine to do this, when the switch is turned to either ON position it would have to energize some sort of holding (electromagnet?) circuit that holds the switch in the on position.

Why do I want this?

Today whenever I first turn on the panel power, I have to always *first* make sure that this switch is in the off position. While this is fine for my use, from an ergonomic/process standpoint that's not quite right: When power's cut to the panel, this switch should always reset itself to off for safety reasons. Some sort of interlock is required to make sure someone doesn't trip up. This would stop having an element turn on when then panel is first turned on. (Especially useful for someone who doesn't use ULWD elements which will pop if not turned on while in water).

Anyone heard of something like this?

Kal