Hi,

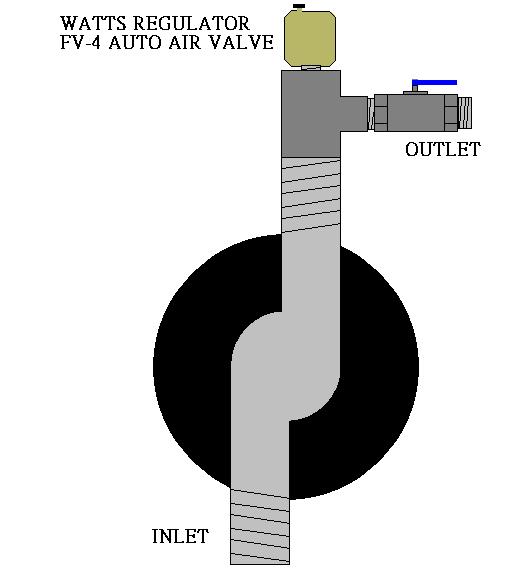

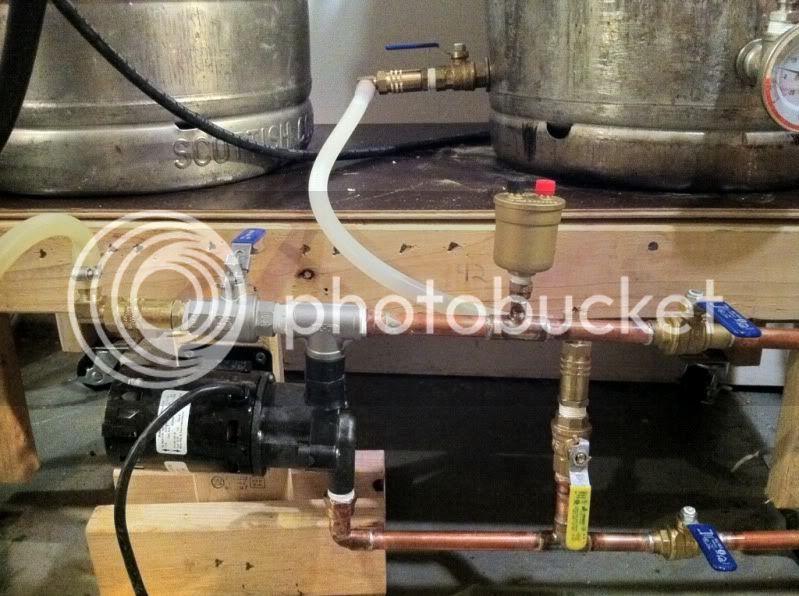

Here is a wee vid that shows the Watts vent seen/discussed here and on the Brewtroller board as a way of allowing a March (or any other flooded inlet type) pump to prime itself without human intervention.

http://www.youtube.com/user/Yergs?feature=mhum

(Oh and you don't need the electrics as they are part of a larger project scope, its a passive mechanical device, which avoids having to move hoses or turn valves to get the priming.)

Here is a wee vid that shows the Watts vent seen/discussed here and on the Brewtroller board as a way of allowing a March (or any other flooded inlet type) pump to prime itself without human intervention.

http://www.youtube.com/user/Yergs?feature=mhum

(Oh and you don't need the electrics as they are part of a larger project scope, its a passive mechanical device, which avoids having to move hoses or turn valves to get the priming.)