You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hot Tub RIMS Tube

- Thread starter bendiy

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Punx Clever

Well-Known Member

- Joined

- Nov 27, 2007

- Messages

- 490

- Reaction score

- 558

I just picked up this:

VersaTherm Universal Heater Assembly 240v/120v

Waiting on some fittings (coming from Derrin at Brewer's Hardware) to finalize the setup then do a test run on an IPA. If I can find a couple CPVC 2"-1/2" NPT bushings locally, I might slap something together to make hot water before my stainless gets in.

Just looking at the part and technical drawings for 2" tri-clover fittings, it should hook up to the flanges on the end no problem. Also have a 1/8" RTD probe coming, it will screw into the pressure taps on the tube.

VersaTherm Universal Heater Assembly 240v/120v

Waiting on some fittings (coming from Derrin at Brewer's Hardware) to finalize the setup then do a test run on an IPA. If I can find a couple CPVC 2"-1/2" NPT bushings locally, I might slap something together to make hot water before my stainless gets in.

Just looking at the part and technical drawings for 2" tri-clover fittings, it should hook up to the flanges on the end no problem. Also have a 1/8" RTD probe coming, it will screw into the pressure taps on the tube.

Lucky_Chicken

Well-Known Member

Love it! i didnt even know these existed... let me know how it works... i may have to shamelessly steal your idea. :rockin:

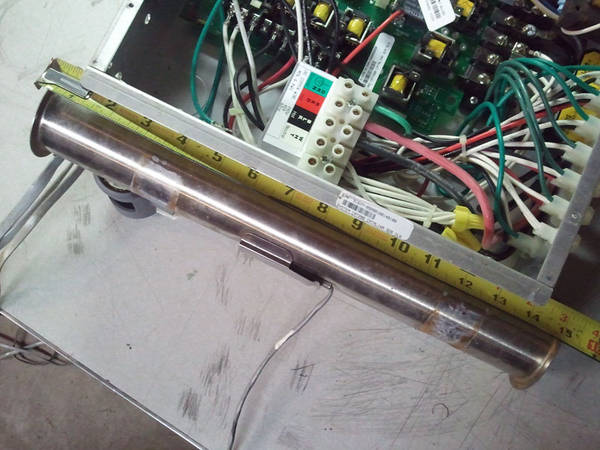

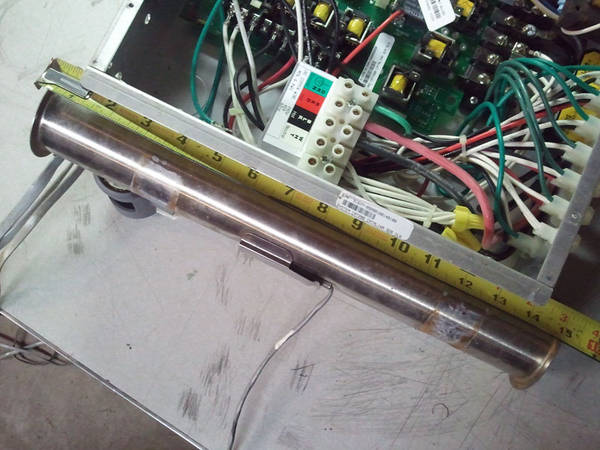

I ask because I've acquired this:

It's an electric control panel for a hot tub / spa with an 4000W 240V heat tube attached.

It's 15" long:

2.75" in diameter:

With a temperature senor attached on the outside:

It also has a pressure / flow sensor that I think it uses to ensure water is flowing through the tube before turning the heating element on:

Here's the inside. It needs a good cleaning:

Here are the electronics:

Side Ports:

It's an electric control panel for a hot tub / spa with an 4000W 240V heat tube attached.

It's 15" long:

2.75" in diameter:

With a temperature senor attached on the outside:

It also has a pressure / flow sensor that I think it uses to ensure water is flowing through the tube before turning the heating element on:

Here's the inside. It needs a good cleaning:

Here are the electronics:

Side Ports:

Awesome find!! Get ahold of darrin at brewers hardware, he would probably be able to answer your question as well as find a part for you. That's alot of electronics in there .. what are the labels on the plugs on the bottom pic. I've got an electrical engineering degree and I'm very curious .. If I lived closer to you I'd love to come over and play with that. I currently have a RIMs based off theelectricbrewery.com design. Once you go RIMs .. you won't go back

Truly intrigued. My wife and I bought a house recently and it came with a hot tub with a severely cracked hottub....

I never saw the brewplication of it.

I never saw the brewplication of it.

Punx Clever

Well-Known Member

- Joined

- Nov 27, 2007

- Messages

- 490

- Reaction score

- 558

I saw lots of used heaters on eBay... didn't pounce because the thought of using a heater that used to make human stew bothered me.

Either way, those are the same measurements as mine, and I think that 2" trial clovers will fit. Remember, fitting sizes are based on the size of tube, not the size of the fittings.

Either way, those are the same measurements as mine, and I think that 2" trial clovers will fit. Remember, fitting sizes are based on the size of tube, not the size of the fittings.

I saw lots of used heaters on eBay... didn't pounce because the thought of using a heater that used to make human stew bothered me.

Either way, those are the same measurements as mine, and I think that 2" trial clovers will fit. Remember, fitting sizes are based on the size of tube, not the size of the fittings.

Good to know. I haven't ever used tri clovers. If that's the case, it should work fine as is.

I got it from the in-laws 10 year old jacuzzi that broke and froze up, so it's used, but at least I know where and by who. The heating element can be replaced, a little bar keepers friend and it's like new.

Punx Clever

Well-Known Member

- Joined

- Nov 27, 2007

- Messages

- 490

- Reaction score

- 558

The only thing I can see going wrong with it is that the control panel probably has an upper limit of 115 F or so.

I've never used tri-clovers before either, but drawings of the fittings from McMaster give me a little more than hope.

I've never used tri-clovers before either, but drawings of the fittings from McMaster give me a little more than hope.

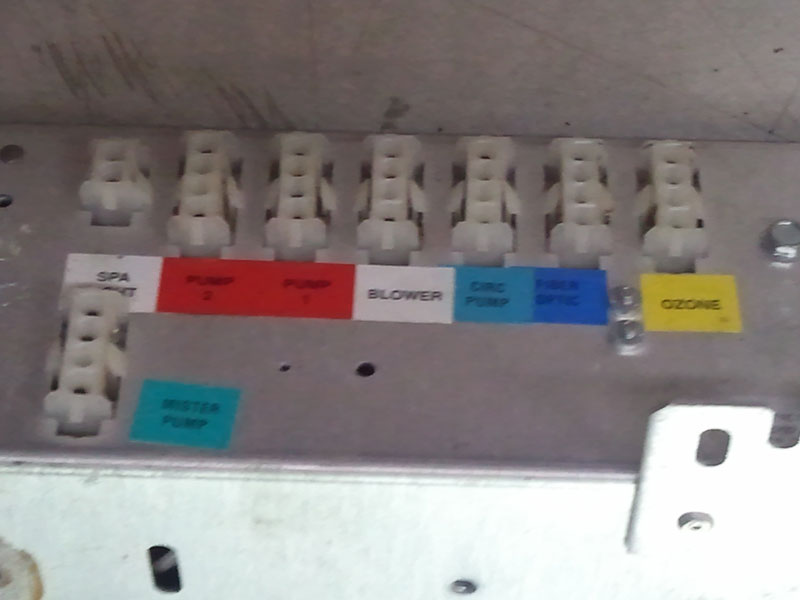

what are the labels on the plugs on the bottom pic.

Here's a closeup on the port labels. They are for the pumps, lights, misters, etc.

There were also some interface controls that are water tight.

The only thing I can see going wrong with it is that the control panel probably has an upper limit of 115 F or so.

I doubt I'll be able to use the control board for it. Unless I can hack the temperature sensor with a voltage divider so it's actual temp is twice what it thinks it is, the IC probably has a hard coded upper limit on the temp. I would have to reprogram or replace the controller IC. I think it will be easier to just use some of the parts in the control box and an SSR and arduino.

Punx Clever

Well-Known Member

- Joined

- Nov 27, 2007

- Messages

- 490

- Reaction score

- 558

I'm just going to use the cheap Auber PID and an SSR with mine. No logging ability, but it's simple and effective.

Punx Clever

Well-Known Member

- Joined

- Nov 27, 2007

- Messages

- 490

- Reaction score

- 558

@Punx

Let me know when you get your 2" tri-clover fittings and if they work. I'll probably order some in the next week or two if it works out for you.

They work. The tube flange could probably be ground down a little, but with some fanagling, it's leak-free. Just be sure to use the actual tri-clover gaskets, not an o-ring like for the sanke conversion.

Punx Clever

Well-Known Member

- Joined

- Nov 27, 2007

- Messages

- 490

- Reaction score

- 558

How was temp management during the test?

I guess it coulda been a leak test. Either way, let us know!!!

I guess it coulda been a leak test. Either way, let us know!!!

Punx Clever

Well-Known Member

- Joined

- Nov 27, 2007

- Messages

- 490

- Reaction score

- 558

It raised temps well on 120 volt... got it up to 100 to program the pid while I'm watching jeapordy and wheel of fortune. More to follow.

Update:

After letting the PID do it's thing, I set it to manual and took 5 gallons of water from 100 to 150 in 34 minutes, then set it to PID mode and let it hold temps. Everything seems to work just dandy with the setup. No leaks after over an hour and a half of pumping/heat.

Update:

After letting the PID do it's thing, I set it to manual and took 5 gallons of water from 100 to 150 in 34 minutes, then set it to PID mode and let it hold temps. Everything seems to work just dandy with the setup. No leaks after over an hour and a half of pumping/heat.

Spring_Chicken

Well-Known Member

Any chance you can list the parts you used and costs?

Looking good.

Looking good.

Punx Clever

Well-Known Member

- Joined

- Nov 27, 2007

- Messages

- 490

- Reaction score

- 558

Ask and ye shall recieve:

https://docs.google.com/spreadsheet/ccc?key=0AoAePys-pI6sdFVBRTdZRVpPZHFjVGJDRk80UmVpekE

I didn't include fittings other than the tri-clover, the pump, or enclosures (including heatsink for the relay) because everyone does things differently.

https://docs.google.com/spreadsheet/ccc?key=0AoAePys-pI6sdFVBRTdZRVpPZHFjVGJDRk80UmVpekE

I didn't include fittings other than the tri-clover, the pump, or enclosures (including heatsink for the relay) because everyone does things differently.

Spring_Chicken

Well-Known Member

Very nice! Thanks

Nice to see it's working Punx. Do you think you are going to grind down the flange on the tube any or does the tri clover clamp fit tight enough to leave it as is?

I need to get my order into Brewers Hardware.

I need to get my order into Brewers Hardware.

Punx Clever

Well-Known Member

- Joined

- Nov 27, 2007

- Messages

- 490

- Reaction score

- 558

Not sure yet. Grinding it down means unhooking the Electrics inside the box.... I'm gonna do a brew day and decide

Punx Clever

Well-Known Member

- Joined

- Nov 27, 2007

- Messages

- 490

- Reaction score

- 558

First brew going on right now... I gotta say, I like this setup. Didn't notice any spot boiling, no extra cables hanging around...

The pictures I posted earlier had a different temperature sensor than I'm using right now. The ports on the hot tub tube allowed me to mount a temperature sensor directly in the tube through the side of the box. very clean.

The pictures I posted earlier had a different temperature sensor than I'm using right now. The ports on the hot tub tube allowed me to mount a temperature sensor directly in the tube through the side of the box. very clean.

CreekBrewery

Well-Known Member

Awesome project Punx! I'm using my xmas and upcoming birthday money to build one of these badboys. Did you use the batch or no sparge method? I do batch right now with no RIMS but I'm interested to hear what works best with this setup.

Punx Clever

Well-Known Member

- Joined

- Nov 27, 2007

- Messages

- 490

- Reaction score

- 558

For yesterday's brew I did a batch sparge on an IPA. Seemed to go well. I think I hit 70% efficiency or something, but I didn't measure my final volume real accurately. I've just always done batch sparges, and figure why not keep doing it.

My advice... don't get a 12v pump. I swear that 12v march 809 was a steal at $55... but after rigging a power supply for it in the box and all the hassle it was...

My advice... don't get a 12v pump. I swear that 12v march 809 was a steal at $55... but after rigging a power supply for it in the box and all the hassle it was...

Kudos for the ingenuity in using the spa tube. I'm glad to hear you made some progress. Too bad you can't get the electronics to work on it. Would be pretty slick to be able to hook your pump up to one of the outlets and be able to turn it on/off with the spa controls.

CreekBrewery

Well-Known Member

Reviewing your parts list because I'm about to make an order and I had a question about the temp sensor. You linked to a threaded RTD sensor. Did you not use the external themowell on the heater?

For my application I need to be able to move the sensor around so I was thinking of the Platinum RTD (RTD (PLT) Sensors : auberins.com, Temperature control solutions for home and industry) but maybe I'm missing something with your design and the sensor you chose works best.

For my application I need to be able to move the sensor around so I was thinking of the Platinum RTD (RTD (PLT) Sensors : auberins.com, Temperature control solutions for home and industry) but maybe I'm missing something with your design and the sensor you chose works best.

Just got my Tri-Clover fittings in from Brewers Hardware. I'm definitely going to grind down my flange. Maybe Punx was smaller, but I cannot get the Tri-Clover clamp on it as is. My flange is 2.75 (Edit 2 7/8) in diameter. I'm going to take off an 1/8 inch all around to bring it to the standard 2.5 (Edit 2 5/8)" diameter for 2" Tri-Clover fittings.

Here's what it looks like stock. I'll post some pics after I modify it.

Here's what it looks like stock. I'll post some pics after I modify it.

Here's some close ups of the sensors. There is a surface mounted temp sensor that slides under a little spring clamp thingy. There is also a pressure sensor. I need to tear this one apart to see how it works, but I think there is a float or something that presses on the sensor. There is also an adjustment wheel so you can fine tune the pressure setting.

I probably will not use the temp sensor like it is mounted here or at all, but it might work as a safety cut off to stop a dry fire. However, I think the pressure sensor will be used for this to detect water in the tube and maybe even if that water is flowing.

I probably will not use the temp sensor like it is mounted here or at all, but it might work as a safety cut off to stop a dry fire. However, I think the pressure sensor will be used for this to detect water in the tube and maybe even if that water is flowing.

Punx Clever

Well-Known Member

- Joined

- Nov 27, 2007

- Messages

- 490

- Reaction score

- 558

Mine was around 2.75" as well. I just managed to get it on there just right so that the clamp would go on. Since I won't be brewing for a while, it may be a good idea to grind it down.

As for the temperature probe... the pressure probe taps are 1/8" NPT. Auber makes an 1/8" RTD probe that will fit in the port... assuming you have a port that clears the element on your tube. This was also a reason why I went with the universal replacement tube, more ports.

The pressure sensor you have there looks like a diaphragm that pushes a rod to open/close a microswitch. Could possibly (depending on how much pressure it needs to trip) be used to prevent the element from going unless the pump was pumping. Just a thought.

Other than the slight oversize on the flange, you can see why this would make an awesome rims tube. When I get a stand built and move to my keggles / keg MLT, I'm going to have the rims tube vertical beside the mash tun, and never worry about air pockets in the tube again.

As for the temperature probe... the pressure probe taps are 1/8" NPT. Auber makes an 1/8" RTD probe that will fit in the port... assuming you have a port that clears the element on your tube. This was also a reason why I went with the universal replacement tube, more ports.

The pressure sensor you have there looks like a diaphragm that pushes a rod to open/close a microswitch. Could possibly (depending on how much pressure it needs to trip) be used to prevent the element from going unless the pump was pumping. Just a thought.

Other than the slight oversize on the flange, you can see why this would make an awesome rims tube. When I get a stand built and move to my keggles / keg MLT, I'm going to have the rims tube vertical beside the mash tun, and never worry about air pockets in the tube again.

Punx Clever

Well-Known Member

- Joined

- Nov 27, 2007

- Messages

- 490

- Reaction score

- 558

I can see it closes much tighter.

I tried to get the clamp on just the tube, no gasket, no second half, but it wouldn't even come close. I almost bent the hinge pin. I'm going to grind it down first. It should work fine after that.

I tried to get the clamp on just the tube, no gasket, no second half, but it wouldn't even come close. I almost bent the hinge pin. I'm going to grind it down first. It should work fine after that.

I've modified my flange by grinding off 1/8 inch all around to reduce the diameter by 1/4 inch total.

I remeasured and found that the flange was actually 2 7/8 inch in diameter. It is now 2 5/8 inch in diameter.

I would not go any smaller than 2 5/8 inch.

This gives you a little more than the standard 2.5 inch fittings. Since the flange is much thinner than the standard fittings, it forces the flange to the largest part of the tri clover clamp (See red arrow in image below). This makes the fitting nice and tight and still gives you some room to tighten the clamp more. I think if you grind it all the way down to 2.5, the screw on the clamp would bottom out before tightening enough.

I remeasured and found that the flange was actually 2 7/8 inch in diameter. It is now 2 5/8 inch in diameter.

I would not go any smaller than 2 5/8 inch.

This gives you a little more than the standard 2.5 inch fittings. Since the flange is much thinner than the standard fittings, it forces the flange to the largest part of the tri clover clamp (See red arrow in image below). This makes the fitting nice and tight and still gives you some room to tighten the clamp more. I think if you grind it all the way down to 2.5, the screw on the clamp would bottom out before tightening enough.

Here is my assembled tub with all the fittings. The brass quick disconnects are from morebeer and the chrome quick disconnects are from bargin fittings. I modified them slightly to be interchangeable. The brass fittings represent my hose connections in the setup, but no hoses are shown.

I should be able to do a water test this weekend.

I should be able to do a water test this weekend.

Punx Clever

Well-Known Member

- Joined

- Nov 27, 2007

- Messages

- 490

- Reaction score

- 558

Lookin good!

Ask and ye shall recieve:

https://docs.google.com/spreadsheet/ccc?key=0AoAePys-pI6sdFVBRTdZRVpPZHFjVGJDRk80UmVpekE

I didn't include fittings other than the tri-clover, the pump, or enclosures (including heatsink for the relay) because everyone does things differently.

So you didnt use the built in sensor?

Punx Clever

Well-Known Member

- Joined

- Nov 27, 2007

- Messages

- 490

- Reaction score

- 558

So you didnt use the built in sensor?

The heater tube I bought was just the tube with an element installed. No control box, no temp sensor, nothing.

I have at Pt100 RTD with 1/8" NPT threads installed in one of the pressure sensor ports on the tube.

My tube came out of a used hot tub. Punx bought his new online. The one he bought has 3 or 4 1/8" NPT fittings built in. The one I have has only one 1/8" NPT fittings that had a pressure sensor on it. The temp sensor on mine just reads the surface temperature of the metal tube. That is the only built in temp sensor. I'll probably measure my temp at the output, but it is nice to have the 1/8" NPT fitting there if I need it.So you didnt use the built in sensor?

Similar threads

- Replies

- 1

- Views

- 510

- Replies

- 0

- Views

- 274

- Replies

- 0

- Views

- 297