what others have said... center support suggested/recommended.

Yes, I definitely will. And this is not to argue with the wisdom/necessity that I do add them, but I still have to emphasize how damn solid this thing is even in its current form. It's a testament to how sturdy these materials are.

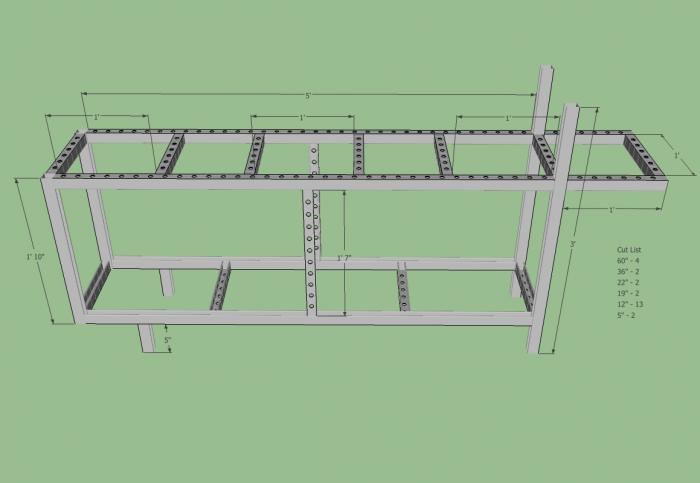

Gifty, I spent some time analyzing my placement of the brackets, and I'm seeing now how I could put it together a bit better. I honestly was frustated how the width of the fittings themselves in between the pieces of strut were throwing off some of my measurements. But your point about using the underside will allow me to remove the fittings from many of the places were they are in between strut. Should make it all fit together a bit better. I'll post more pics as I progress.

Thanks all.