I built my first coffin keezer back in the summer of 2010 using an old Whirlpool freezer that was the perfect size to hold 6 cornies on the floor and 2 on the hump with a collar. It was my first attempt at a project like this and I learned A LOT from the build. Unfortunately the compressor crapped out on the freezer about this time last year and I was forced to scrap the entire thing due to the way I built it. Using my Sawzall to tear apart that keezer was one of the hardest things I've ever had to do. I tried to get it fixed but nobody would even come out to look at it because it was fully encased in tongue-and-groove pine paneling and the freezer couldn't be removed.

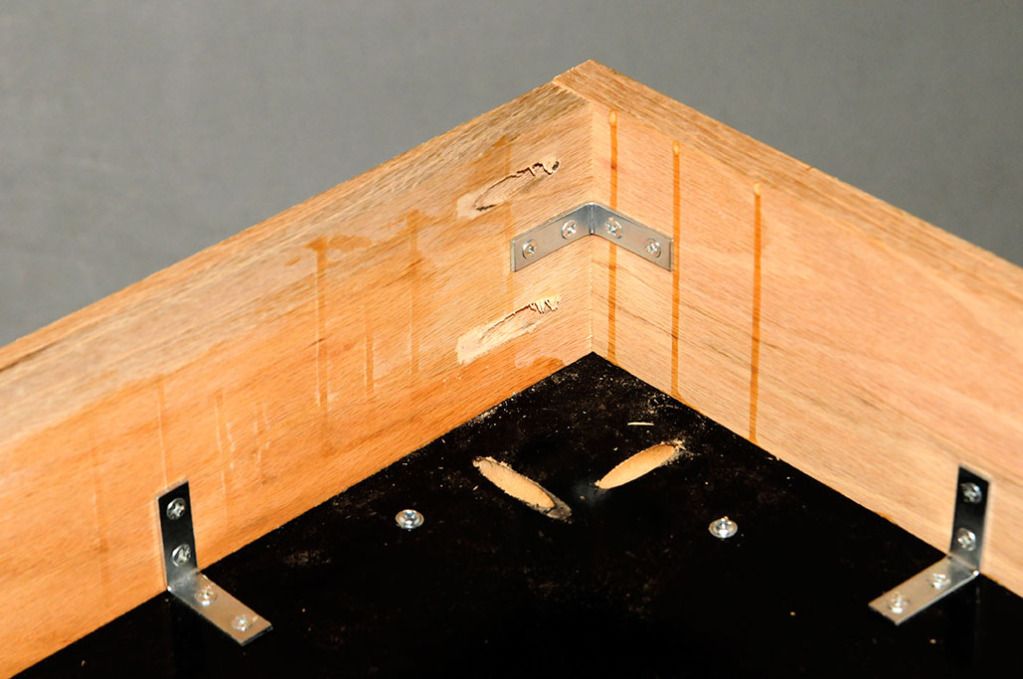

Which leads me to the three key lessons I learned from my first build. 1) Build the cabinet so that the freezer can be easily removed if necessary. 2) Use a freezer that you can easily swap out with a same-sized unit if needed. 3) Use a new or relatively new freezer, not one that is 10+ years old.

My original keezer had a 6 inch collar that was connected to the freezer with liquid nails. I attached the t & g pine directly to the collar and also to the base that I build. There was a small plastic ridge around the upper lip of the freezer that I didn't account for so there was also a small buldge in paneling, creating a small gap of about 0.5 cm between the panels and the freezer skin. The pine would get pretty warm while the compressor was running and I'm pretty sure that this caused the compressor to run much more than it should have, and this is what caused the compressor to die.

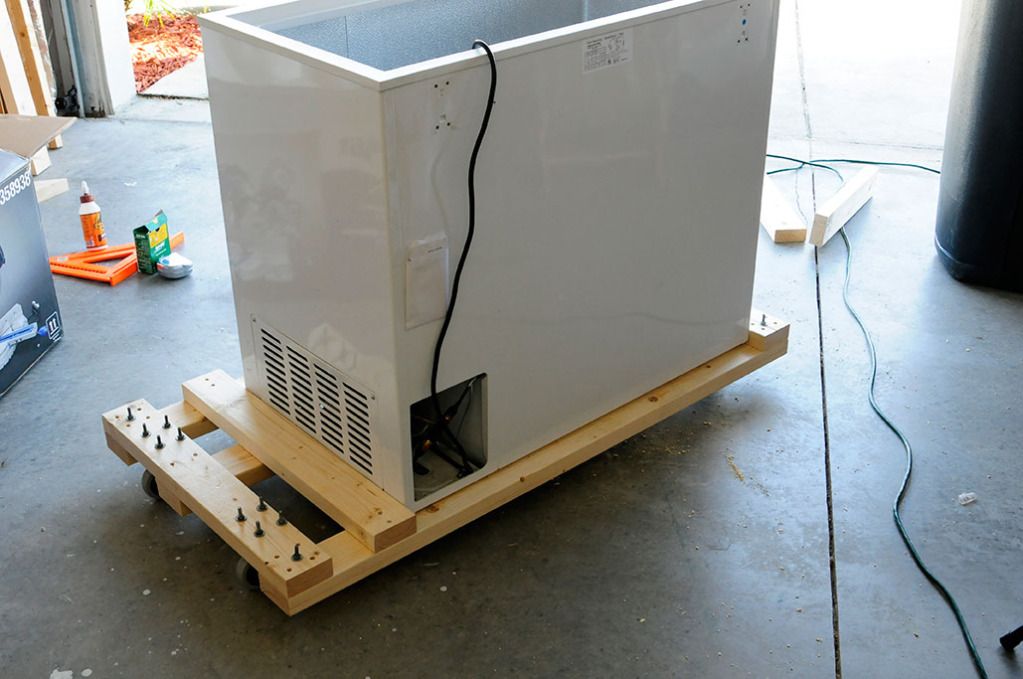

I am now embarking on my second attempt at a coffin keezer build, armed with much more knowledge, better tools, and a fair amount more wood working experience than I had in 2010 with my first build. I will be using the 7.0 GE freezer that has been used by many others. This unit was attractive to me because it can hold 4 on the floor and one on the hump (I will be putting a 2.5 or 3 gallon on the hump). I considered the 8.8 and 10.2 Danby freezers but am trying to keep the scale of this build a little smaller than my last build. I picked up a used 7.0 GE from Craigslist for $100, it's 2 years old and is in very good condition.

I was initially worried that SWMBO would not allow me to build a new keezer, however she is in full support of my build. In fact, she even surprised me with an AWESOME idea that I hadn't even considered. There was really only one place in our house that I could put this keezer and that was in the landing directly inside of the front door, it would literally be the first thing you saw when you can in the house. I was fine with it being there but SWMBO wasn't so sure. We kept the first keezer in the living room until our son was born in Sept 2011, it was then moved into my office. The office has since been converted to a playroom for our son and we have changed the layout of our living room and the keezer will no longer fit. SWMBO's idea was to sell the formal dining room table and put the keezer in that room, converting the space to more of a bar/game room. I was shocked when she suggested this but it's perfect. We have only used the dining room table 3 times in the 2 years since we moved in to this house, so we will not miss it. The only downer is that I'm probably going to loose my a$$ on the table, I paid $1800 new for it and will be doing good if I get $1000 for it.

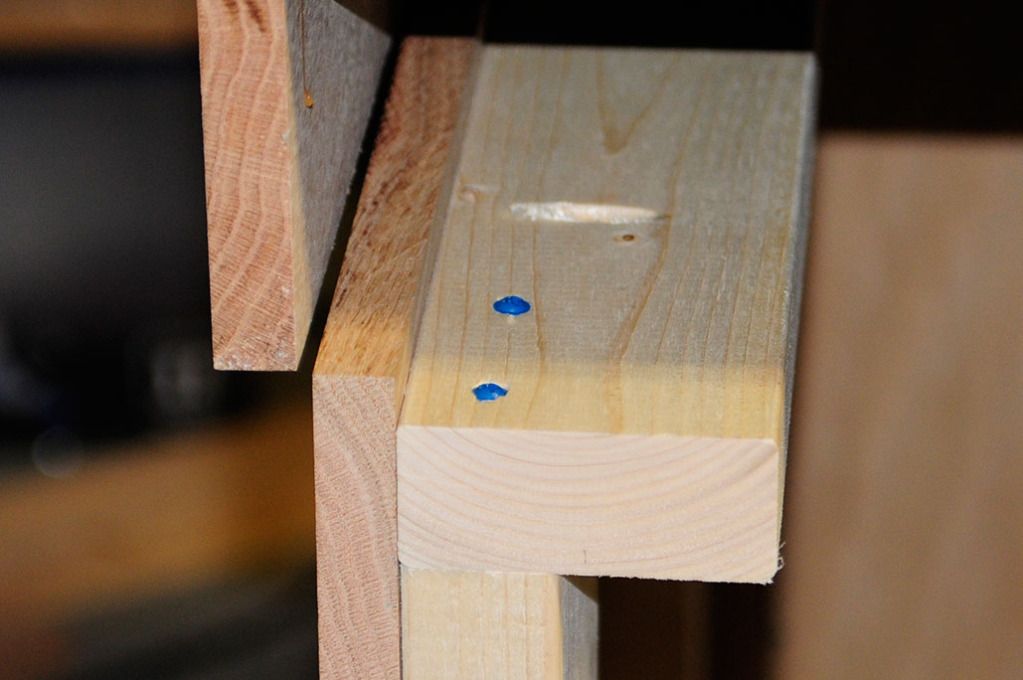

Anyways, enough of my long winded first post. I will be starting construction this week and hope to get most of the cabinet and lid built. I will try to take as many photos as possible and will post them back here as I have time.

In loving memory of my first keezer, here is a photo of her after I finished construction.... I eventually added a 5th nitro tap in the middle.

Which leads me to the three key lessons I learned from my first build. 1) Build the cabinet so that the freezer can be easily removed if necessary. 2) Use a freezer that you can easily swap out with a same-sized unit if needed. 3) Use a new or relatively new freezer, not one that is 10+ years old.

My original keezer had a 6 inch collar that was connected to the freezer with liquid nails. I attached the t & g pine directly to the collar and also to the base that I build. There was a small plastic ridge around the upper lip of the freezer that I didn't account for so there was also a small buldge in paneling, creating a small gap of about 0.5 cm between the panels and the freezer skin. The pine would get pretty warm while the compressor was running and I'm pretty sure that this caused the compressor to run much more than it should have, and this is what caused the compressor to die.

I am now embarking on my second attempt at a coffin keezer build, armed with much more knowledge, better tools, and a fair amount more wood working experience than I had in 2010 with my first build. I will be using the 7.0 GE freezer that has been used by many others. This unit was attractive to me because it can hold 4 on the floor and one on the hump (I will be putting a 2.5 or 3 gallon on the hump). I considered the 8.8 and 10.2 Danby freezers but am trying to keep the scale of this build a little smaller than my last build. I picked up a used 7.0 GE from Craigslist for $100, it's 2 years old and is in very good condition.

I was initially worried that SWMBO would not allow me to build a new keezer, however she is in full support of my build. In fact, she even surprised me with an AWESOME idea that I hadn't even considered. There was really only one place in our house that I could put this keezer and that was in the landing directly inside of the front door, it would literally be the first thing you saw when you can in the house. I was fine with it being there but SWMBO wasn't so sure. We kept the first keezer in the living room until our son was born in Sept 2011, it was then moved into my office. The office has since been converted to a playroom for our son and we have changed the layout of our living room and the keezer will no longer fit. SWMBO's idea was to sell the formal dining room table and put the keezer in that room, converting the space to more of a bar/game room. I was shocked when she suggested this but it's perfect. We have only used the dining room table 3 times in the 2 years since we moved in to this house, so we will not miss it. The only downer is that I'm probably going to loose my a$$ on the table, I paid $1800 new for it and will be doing good if I get $1000 for it.

Anyways, enough of my long winded first post. I will be starting construction this week and hope to get most of the cabinet and lid built. I will try to take as many photos as possible and will post them back here as I have time.

In loving memory of my first keezer, here is a photo of her after I finished construction.... I eventually added a 5th nitro tap in the middle.

whoopsies

whoopsies