Ok, I've got the go ahead from SWMBO to convert my operation to natural gas.

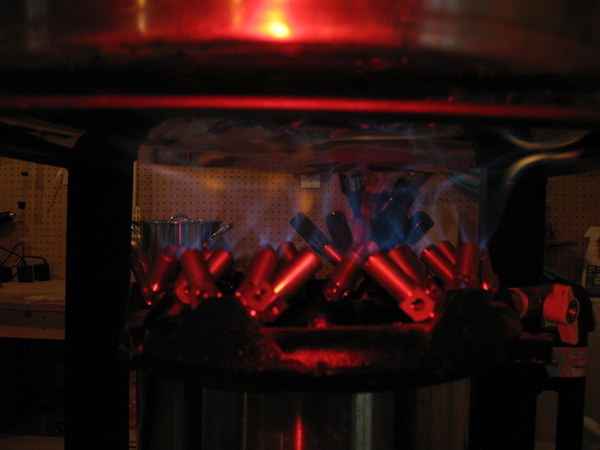

Currently, I have a B3 sculpture with propane burners--my brew room has a gas line already, so it'll be a simple conversion of changing out the burners and running the line.

Question is one regarding CO production--

I'm going for 200,000 BTU burners, and this thing is inside. I don't want to fork over the change for a hood vent, but I might have to.

Anyone else brew AG indoors with natural gas, and if so, what kind of ventilation do you use??

I do have an outside door to the room, and I was thinking of putting in a CO meter, open the door, turn on a fan for cross ventilation, and monitor CO levels, but this might prove woefully inadequate.

Thoughts and ideas are appreciated!!

Currently, I have a B3 sculpture with propane burners--my brew room has a gas line already, so it'll be a simple conversion of changing out the burners and running the line.

Question is one regarding CO production--

I'm going for 200,000 BTU burners, and this thing is inside. I don't want to fork over the change for a hood vent, but I might have to.

Anyone else brew AG indoors with natural gas, and if so, what kind of ventilation do you use??

I do have an outside door to the room, and I was thinking of putting in a CO meter, open the door, turn on a fan for cross ventilation, and monitor CO levels, but this might prove woefully inadequate.

Thoughts and ideas are appreciated!!