kylekestell

Member

Anyone have any thoughts on how well this would work?

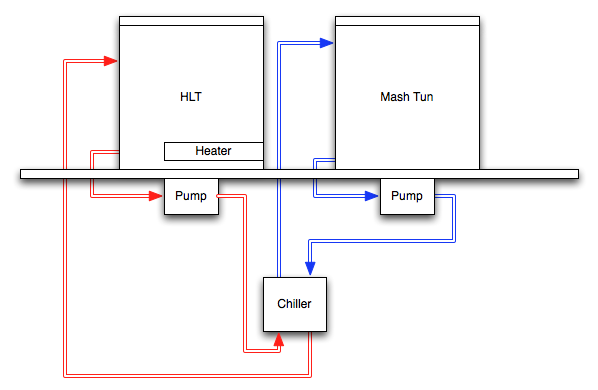

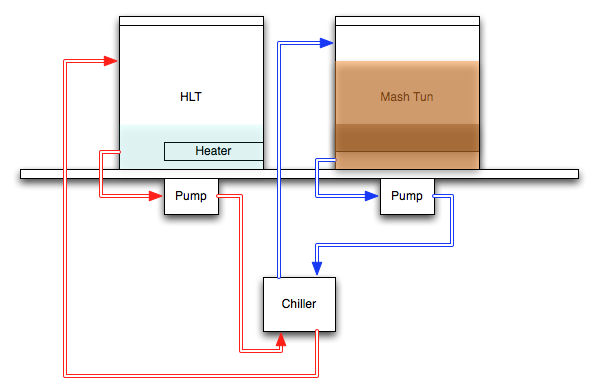

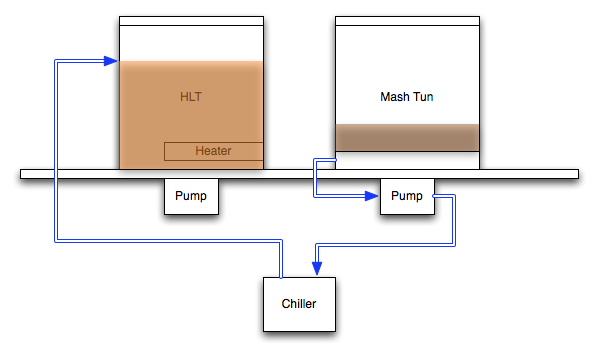

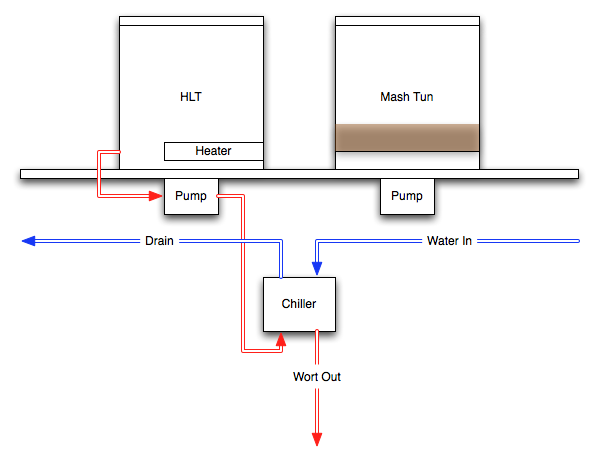

I'm imagining recirculating temperature controlled water through the outer tube, and sweet wort through the inner tube. A PID controller controls a heating element in the hot liquor tank; the PID's thermocouple measuring the temperature of the sweet wort as it leaves the heat exchanger.

I'm imagining recirculating temperature controlled water through the outer tube, and sweet wort through the inner tube. A PID controller controls a heating element in the hot liquor tank; the PID's thermocouple measuring the temperature of the sweet wort as it leaves the heat exchanger.