I'd start by making sure eKettle with PID control is what you really want for you task.

10 gallon kettle, I'm sure your goal is 5 gallon batches. At 120V, household circuits will limit you to a 2000W element. To be available to run on *any* household circuit, you would need to knock that down to 1500W (run on a 15A circuit). Your kitchen should have 20A (can run the 2000W) circuit(s) but they may not have the right 20A outlets in place for those.

My eKettle is 3000W and it

just barely has enough power to get a boil going. You'll be at least 1000W short of that, so you'll need the stove on full-time. Once the stove is going full-time, the attraction of being able to "dial in your boil" using the PID is largely gone - you can just adjust the stove. You're also worrying about protecting the element housing/cord from the stove itself.

I'm all for projects, and would love to help you do this one safely, but I'm wondering if you wouldn't like a 1500W or 2000W heat stick more than a stove-assist ekettle. You could build a nice one with an on/off switch (or even PMW if you want some control - scope out a few recent threads on the topic) for a pretty good price. I loved having one...little extra heat for the mash tun here, little boost for our turkey fryer burner over there.

To answer some of the questions you actually asked-

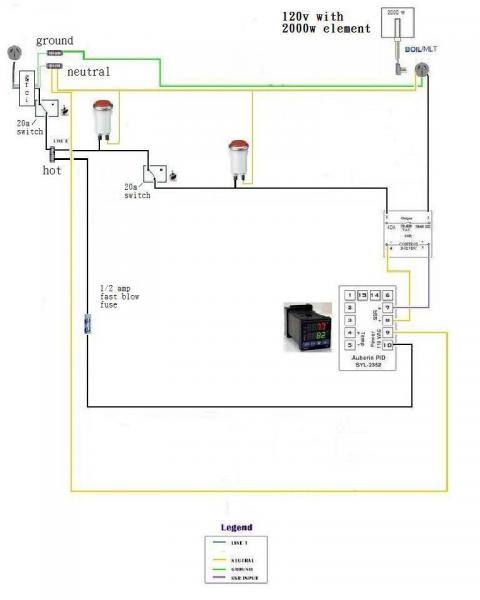

Fuses aren't really important, but I incorporated a few choice ones sourced from Radio Shack. It's incredible, but they do still sell this stuff. You just put them inline before whatever you're trying to protect.

Fuse Holder

Fuses - Fast acting is what you're looking for if you want to, for example, protect your PID. Check the specs on your particular device, but 0.5A or so should be fine, if it's blowing the fuse in normal operation just bump up in size slightly.

Big spending on tools is also not required. While the punch tools are nice, I'm sure, by being careful and going slowly, we put 5 holes in my stainless steel kettle with a step bit without incident.