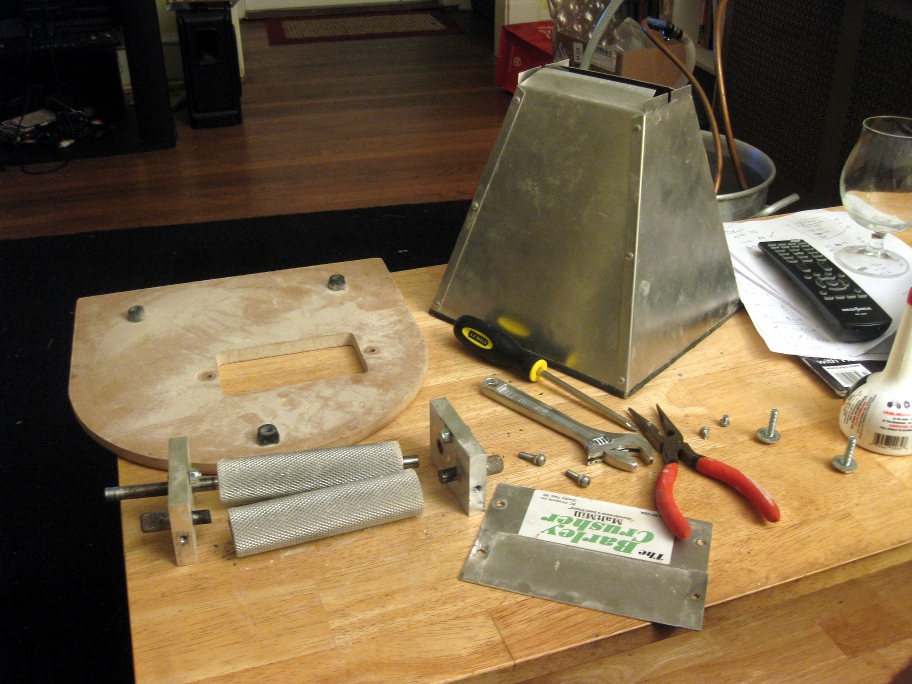

The Cereal Killer arrived today in perfect condition. It was packed with care and even had styrofoam protecting the dowels on the base. As promised I tore it all apart, because that's what I do. I intended to build my own mill but for $89, my time is worth more than that. I am not disappointed, rather I'm impressed at the value that this mill offers. Two things I'll point out, the ad says it's anodized and my ohmmeter says otherwise, it's raw aluminum. The ad also says the rollers are hardened, I see no evidence of heat treatment but I didn't want to drag a file across the roller to see.

The mill without the wood base weighs 5 pounds 3oz.

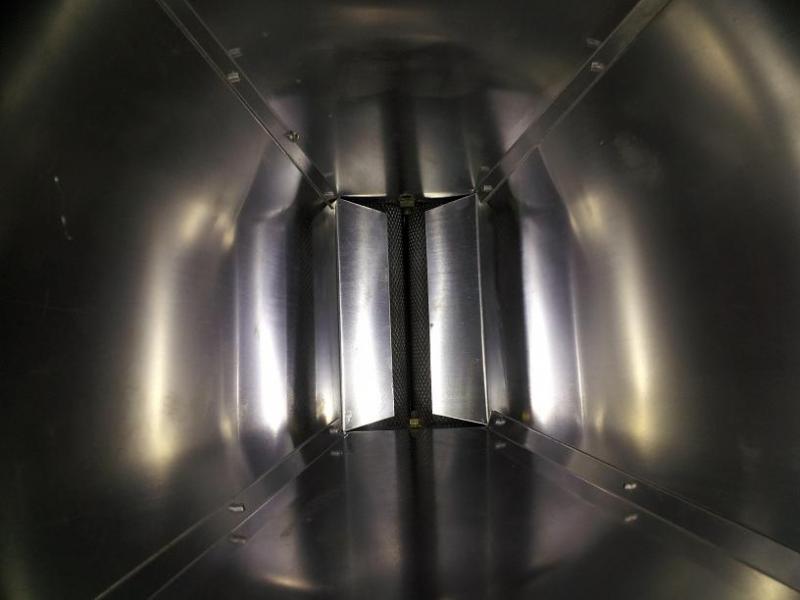

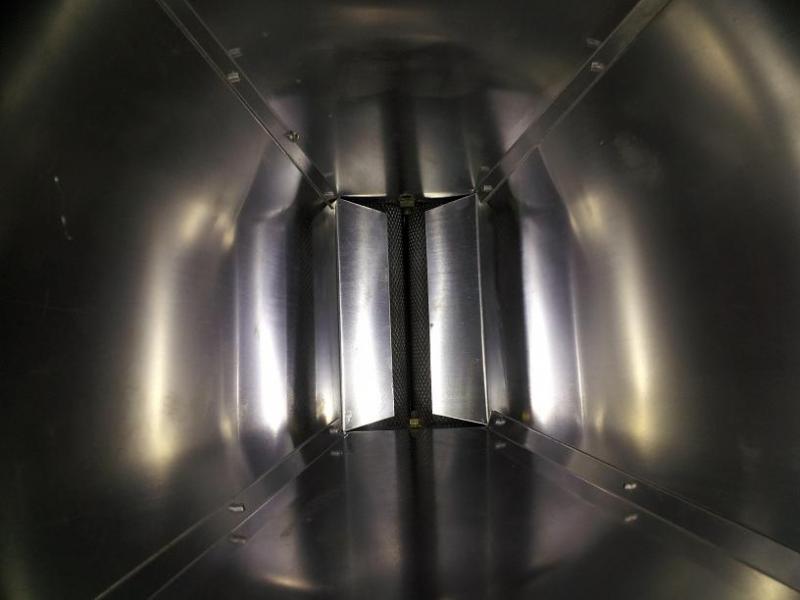

The hopper is made from .0325" aluminum sheet, it is professionally sheared and brake formed. It is assembled with aluminum pop rivets. More than adequate for the job. Two screws secure it to the roller assembly. They thoughtfully slotted the hopper so if you need to remove it, you simply have to loosen the screws and lift it off.

The mill is secured to a wood base with two metric cap screws, the base is 5/8" cabinet plywood. I would have expected MDF on a value mill. There are three locator dowels on the bottom to keep it centered on a 5 gallon bucket.

The mill can be reversed on the base which would allow you to mount a small motor directly to the base, you could squeak an 1.5" drive pulley on the shaft. Perhaps a cog belt style to make the best use of the clearance.

With the base & the hopper removed we are down to the mill itself. The front & rear plates are .0625" aluminum each held in place by four screws. The aluminum was cosmetic grade in that it had a blue protective covering to prevent it from getting scratched up during machining, typically this cost more.

The mill is advertised as being ball bearing and indeed it is. The side plates each have a 6800Z bearing for the drive roller.

The idler roller has 698Z bearings pressed into each end of the roller.

The eccentrics engage the bearings and rotate in the side plate to adjust the roller gap. The thumb screws tighten against the slot in the eccentrics.

The rollers are 5 inches long and measure 1.281 inches in diameter and the diameter is consistent the length of each roller. The rollers are fully knurled to depth as evident by the sharp points on the diamonds.

All the fastener holes were chamfered & de-burred. Disassembly and assembly was easy, everything was slip fit. The .053" gap mark indicated is pretty close as verified with a feeler gage. Max gap is .106" and the minimum gap indicated is 0. It's easy to set the gap and lock it in place with the thumb screws which also have a jam nut to keep them from backing off.

About the only improvement that I can think of at this time would be the addition of some thin plastic shim stock on each roller end to prevent roller contact with the aluminum side plates. something .010" would be good. A metal shim could be used as well.

There are a few other views of it posted in my gallery.

In summary, for $89 delivered to the door, it's a heck of a value.

ETA, I ran across some photos of a Barley Crusher that was taken apart, the Cereal Killer is pretty much a dead ringer clone of a Barley Crusher except the Barley crusher has bushings.

ETA

I did some digging and came across the pics of the Barley Crusher disassembled. Wanted to make sure the pics were credited to their rightful owners. I prefer the Cereal Killer construction.

There are some detail pics in this thread:

Cleaning the Barley Crusher

And from this blog:

Barley Crusher Taken Apart