You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bad News Brewery - Control Panel

- Thread starter BadNewsBrewery

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

BadNewsBrewery

Well-Known Member

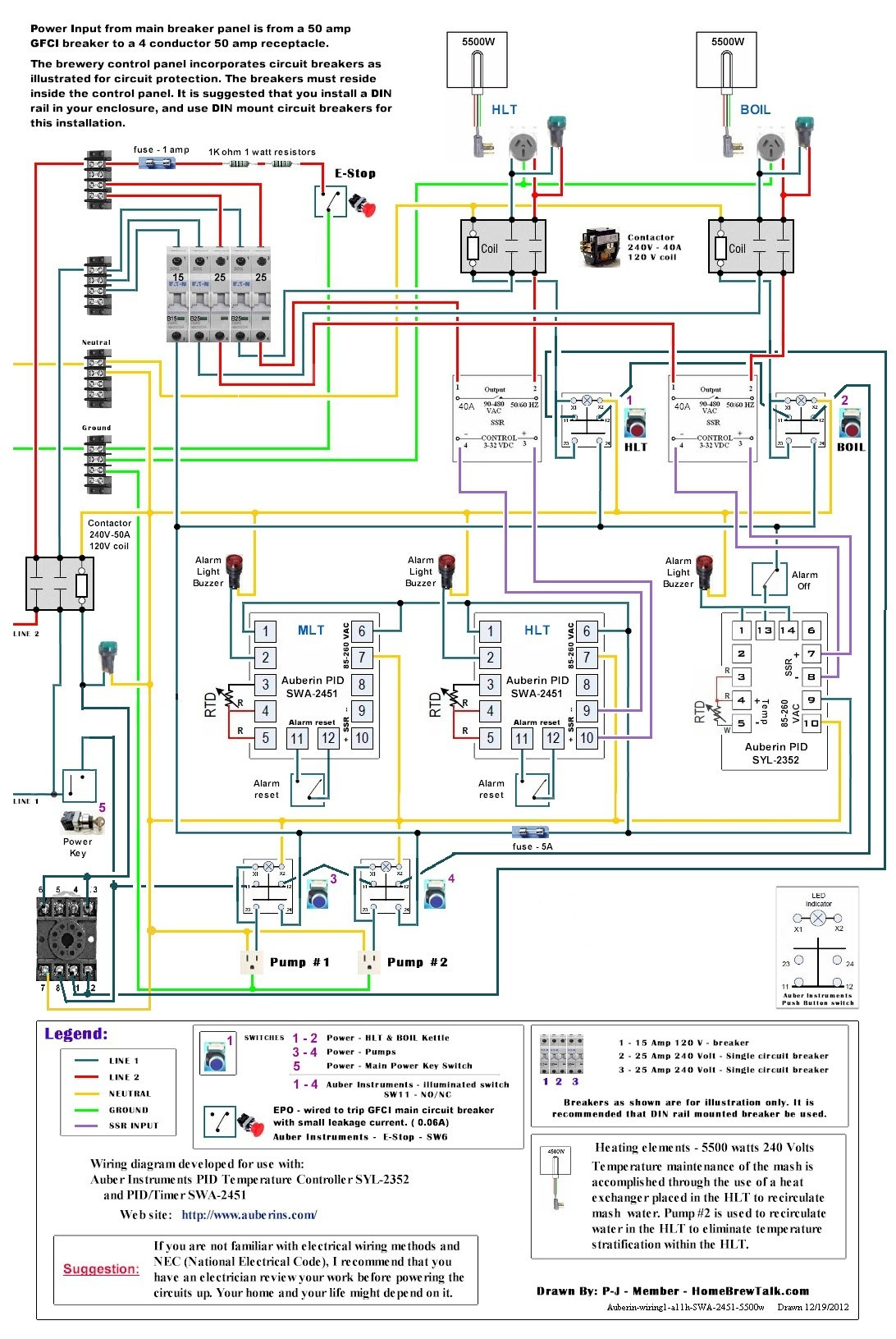

I have everything wired. I'm in the process of cleaning up the runs and doing point-to-point continuity testing on all the wires to make sure I have it wired up like I want. I seriously underestimated the amount of time it takes to wire these up and to do it well. The wiring diagram was priceless.

I'll upload photos tonight if I get it wrapped up, before I plug it in and blow everything sky-high.

Then it's time to finish the last few holes in the kettles and on to brewing!

I'll upload photos tonight if I get it wrapped up, before I plug it in and blow everything sky-high.

Then it's time to finish the last few holes in the kettles and on to brewing!

BadNewsBrewery

Well-Known Member

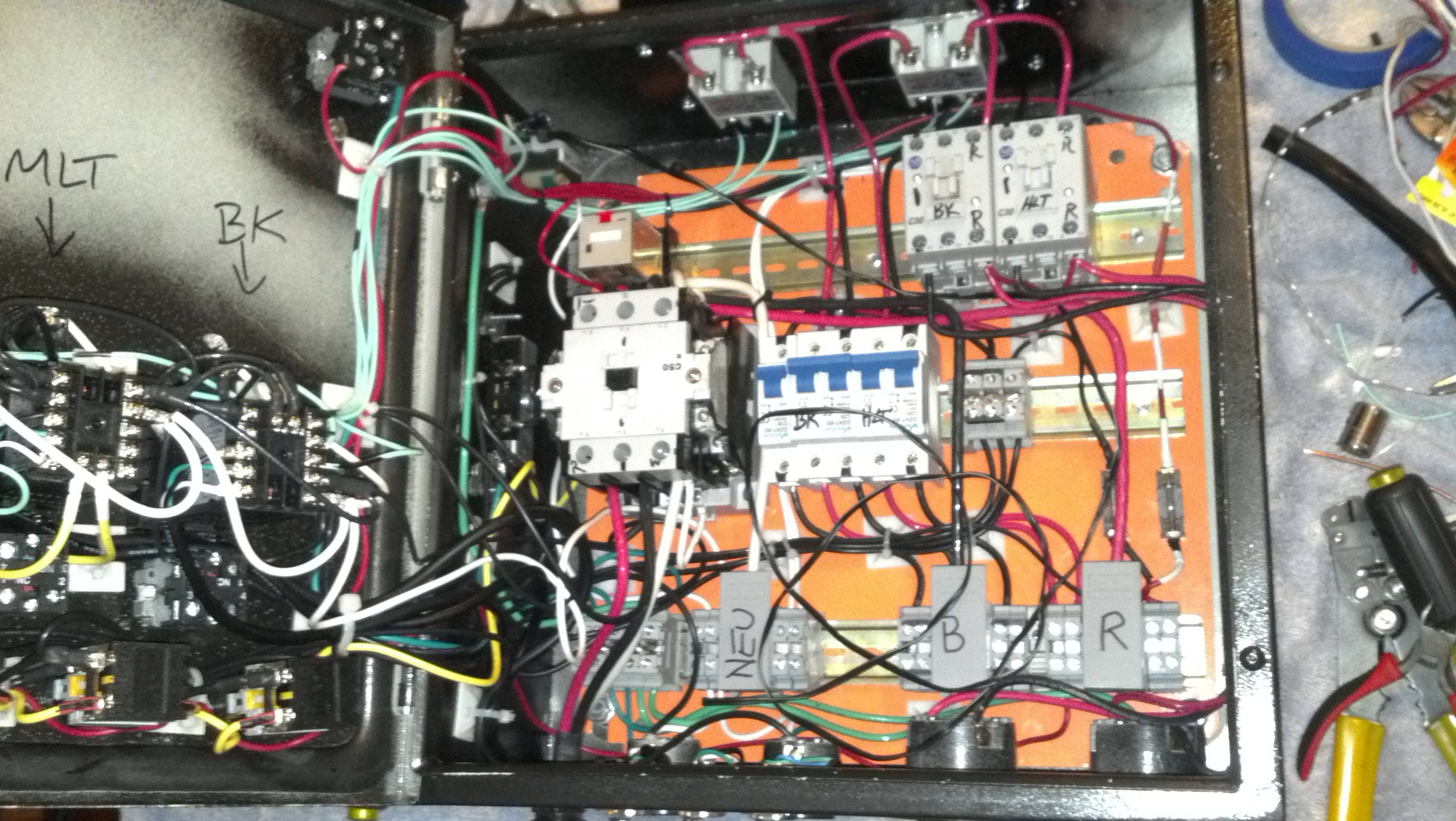

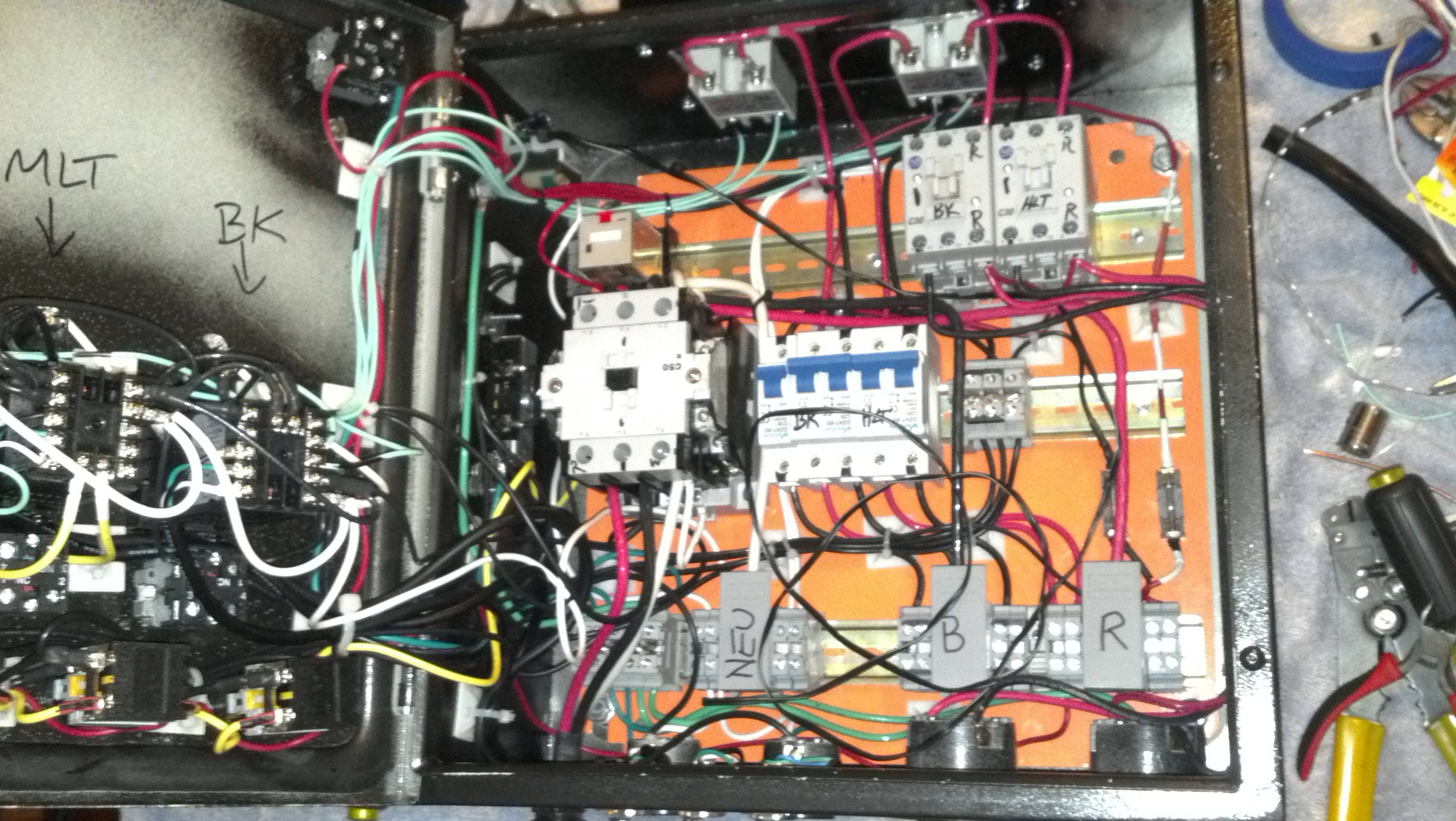

So great news - finished the panel, checked the circuits, everything looked good.

Plugged it in, turned on the breaker - no smoke. Good start.

(never mind the weird random black wire in the middle - that's the feed to my LEDs for the backlight box, once I finish it)

Turned on the key - nada. After some checking, realized I ran the safe-start-interlock relay neutral to downstream of the main contactor - :smack:. Swapped to be connected before the contactor, flipped the switch and....

BUZZZZZ

After some trouble shooting, it's evident that I was sent a sub-par contactor. It was listed as 'new' on eBay, but when I got it there was obvious damage and an attempted repair. I didn't complain because hey - if it works, it'll live inside the panel. Well... it didn't work, and now they want me to send it back (my expense) to refund the purchase cost. I'll be out the shipping cost to get it here and to get it back (about the same cost as the contactor itself) and will have nothing. I'm not too fond of that idea - like hell I'm paying $20 something to get nothing but disappointment and let down.

Once I get a new contactor, should be able to continue the process of trouble shooting. Was planning to brew this weekend - doesn't look like that's happening.

-Kevin

Plugged it in, turned on the breaker - no smoke. Good start.

(never mind the weird random black wire in the middle - that's the feed to my LEDs for the backlight box, once I finish it)

Turned on the key - nada. After some checking, realized I ran the safe-start-interlock relay neutral to downstream of the main contactor - :smack:. Swapped to be connected before the contactor, flipped the switch and....

BUZZZZZ

After some trouble shooting, it's evident that I was sent a sub-par contactor. It was listed as 'new' on eBay, but when I got it there was obvious damage and an attempted repair. I didn't complain because hey - if it works, it'll live inside the panel. Well... it didn't work, and now they want me to send it back (my expense) to refund the purchase cost. I'll be out the shipping cost to get it here and to get it back (about the same cost as the contactor itself) and will have nothing. I'm not too fond of that idea - like hell I'm paying $20 something to get nothing but disappointment and let down.

Once I get a new contactor, should be able to continue the process of trouble shooting. Was planning to brew this weekend - doesn't look like that's happening.

-Kevin

Contactors & Relays auberins.com

Call them and you can get it in a day or 2.

Call them and you can get it in a day or 2.

BadNewsBrewery

Well-Known Member

P-J,

I plan to run both elements at the same time, so I am looking for a 50a contactor. I'm also looking for a 3-pole contactor as the one I had before was set up for that and I wired it that way. I suppose I can run the neutral straight to the terminal block, but if I can get the seller on eBay to ship me what I ordered but NOT broken, I'll be better off.

Thanks for the suggestion. And thanks for the help - that wiring diagram saved my ass a LOT of headache trying to wire things up.

-Kevin

I plan to run both elements at the same time, so I am looking for a 50a contactor. I'm also looking for a 3-pole contactor as the one I had before was set up for that and I wired it that way. I suppose I can run the neutral straight to the terminal block, but if I can get the seller on eBay to ship me what I ordered but NOT broken, I'll be better off.

Thanks for the suggestion. And thanks for the help - that wiring diagram saved my ass a LOT of headache trying to wire things up.

-Kevin

This one Contactor, 2 pole 40 A, 120V Coil Is rated for 40A with an inductive load but it is rated for 50A with a resistive load. Resistive is what we do.

Oh, and BTW you do not need to switch the neutral at all.

Just saying.

Oh, and BTW you do not need to switch the neutral at all.

Just saying.

BadNewsBrewery

Well-Known Member

Well then - if the seller doesn't want to replace my contactor and just wants to give me my money back, I'm going with Auber (where I should have gone in the first place).

Any idea if this will mount to a DIN rail? From the image I'm guessing no.

-Kevin

Any idea if this will mount to a DIN rail? From the image I'm guessing no.

-Kevin

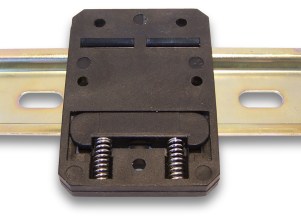

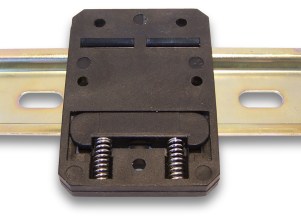

Those auber contactors are not din mountable. I have them and I ordered some mounts for them from mouser. The product itself is from altech, I am at work right now so I dont have the exact part number but I you want it let me know and I can look it up. I put 2 of the mounts on each contactor an they were only like $0.60 if I rember correctly.

BadNewsBrewery

Well-Known Member

Thanks for the info. If you have a specific part number that'd be clutch. Mouser is a tough website to navigate if you don't know EXACTLY what you're looking for. Did you use something more like this:

or this:

Thanks,

-Kevin

EDIT - Looks like the seller is being a PITA and I'm going to have to resolve it through PayPal... off to Auber to get their contactor. The DIN adapter will be a big help.

or this:

Thanks,

-Kevin

EDIT - Looks like the seller is being a PITA and I'm going to have to resolve it through PayPal... off to Auber to get their contactor. The DIN adapter will be a big help.

BadNewsBrewery

Well-Known Member

Thank you! 3 on the way - for the price, a spare is cheap insurance!

Jps101

Well-Known Member

I am thinking and thinking and want to go this direction. Here's an odd question, perhaps. I see that most use a plug to attach power to the CP, is there a reason NOT to hardwire the box to a cable/line that would then plug into a 30/40/50 amp outlet. I am thinking of a dryer. It is hardwired and you simply plug it in. Thoughts?

BadNewsBrewery

Well-Known Member

That's what I did - I figured it's much easier to drill a small 3/4"-1" hole for a liquid tight connector than cutting a big hole for a panel mounted plug, and cheaper too.

Downside - I'm not really sure there is one. I wonder how often the folks with the plug end on their panels actually unplug them, or if they are essentially hard wired. I suppose if your outlet is inconvenient to get to, unplugging at the panel makes sense. My outlet is about 4' away so easy day.

Downside - I'm not really sure there is one. I wonder how often the folks with the plug end on their panels actually unplug them, or if they are essentially hard wired. I suppose if your outlet is inconvenient to get to, unplugging at the panel makes sense. My outlet is about 4' away so easy day.

BadNewsBrewery

Well-Known Member

Got the new contactor wired and installed. The safe start interlock worked exactly as described and the new contactor as well. My panel finally has life. Unfortunately, there's something wrong and I'm getting stray voltage all over the place. I need to spend some more time troubleshooting but there's a good chance I'll be throwing my issues up here soon in search of your help. Fingers crossed.

BadNewsBrewery

Well-Known Member

So for some reason two of my switches weren't working right. Pulled them and tested each operation individually and they seem to work fine, which tells me I have a bad wire somewhere.

Also, with the switch that I use to run my contactors between the SSR and the receptacles - if I take a voltage reading across the switch output (with the switch open) to either Hot A or Hot B I get somewhere around 100 volts. It seems as though my output line is running to neutral through the coil of the contactor. Is it normal to get those kinds of leakage currents through the coil when it's not engaged?

Also, with the switch that I use to run my contactors between the SSR and the receptacles - if I take a voltage reading across the switch output (with the switch open) to either Hot A or Hot B I get somewhere around 100 volts. It seems as though my output line is running to neutral through the coil of the contactor. Is it normal to get those kinds of leakage currents through the coil when it's not engaged?

BadNewsBrewery

Well-Known Member

So here's a picture to help - if I take a reading from 24 to black (Hot A), with the switch not depressed (23/24 is NO, so no power), I get a voltage reading. If I pull the neutral from the coil of the contactor, I get no voltage reading. Is this normal, or is there a problem with my contactors?

That is normal. Nothing wrong with that.So here's a picture to help - if I take a reading from 24 to black (Hot A), with the switch not depressed (23/24 is NO, so no power), I get a voltage reading. If I pull the neutral from the coil of the contactor, I get no voltage reading. Is this normal, or is there a problem with my contactors?

BTW: Do you have a diagram showing the total wiring plan? The safe start interlock setup is what I'd like to see.

BadNewsBrewery

Well-Known Member

I copied what Kal did on his website. I will incorporate it into the diagram you made for me. I should have time later today to work on something.

BadNewsBrewery

Well-Known Member

Alright - I got the switches working. I had run them at 240v, with Hot A to X1 and Hot B to X2 through the NO portion of the switch. So, with the contactor 'leaking' neutral, I wound up getting 120V from X1 to X2. So I changed the feed to X1 to neutral and now the lights only come on with the switch depressed.

New problem though... the element LEDs come on when the element contactors are turned on, regardless of what the SSR is doing. I run power to the light from the red and black lines downstream of the contactor, just like in my wiring diagram. In theory, the SSR limits the juice flowing to the red line, so it should only turn the LED on when the SSR is switched on.

I took some readings to see if I could figure out what was wrong. All measurements taken from the downstream contactor red line to either the white (neutral), black (Hot), and Red (should be zero... red to red...) Here they are:

SSR off / Contactor Open (off) - 115 (W) / 2 (B) / 240 (R)

SSR off / Contactor Closed - 66 (W) / 54 (B) / 185 (R)

SSR on / Contactor Open - 115 (W) / 2 (B) / 240 (R)

SSR on / Contactor Closed - 120 (W) / 240 (B) / 2 (R)

So, in condition 1, it looks like the red line coming off the contactor is acting like a Black line to cause a reading of 240.

Condition 2 - no clue where those numbers are coming from. SSR leakage?

Condition 3 - Black again

Condition 4 - Red - the only time it's actually right.

What the hell is going on here?!

New problem though... the element LEDs come on when the element contactors are turned on, regardless of what the SSR is doing. I run power to the light from the red and black lines downstream of the contactor, just like in my wiring diagram. In theory, the SSR limits the juice flowing to the red line, so it should only turn the LED on when the SSR is switched on.

I took some readings to see if I could figure out what was wrong. All measurements taken from the downstream contactor red line to either the white (neutral), black (Hot), and Red (should be zero... red to red...) Here they are:

SSR off / Contactor Open (off) - 115 (W) / 2 (B) / 240 (R)

SSR off / Contactor Closed - 66 (W) / 54 (B) / 185 (R)

SSR on / Contactor Open - 115 (W) / 2 (B) / 240 (R)

SSR on / Contactor Closed - 120 (W) / 240 (B) / 2 (R)

So, in condition 1, it looks like the red line coming off the contactor is acting like a Black line to cause a reading of 240.

Condition 2 - no clue where those numbers are coming from. SSR leakage?

Condition 3 - Black again

Condition 4 - Red - the only time it's actually right.

What the hell is going on here?!

grandequeso

Well-Known Member

I bet if you ran the lights at 120v you would not have that problem. if you're using the ones auber sells I believe they say you can run them at 120v, they'll. Just be a little bit less bright . Id rather just have my lights running off the contactor personally. the pid output light is enough for me. watching the light flutter on & off every few seconds would annoy me.

BadNewsBrewery

Well-Known Member

I tried running it at 120v and got the same results as on 240v.

Yes, I could run it such that the green light is on every time the contactor is closed, but I have illuminated buttons, so when I turn on the contactor the LED in the button lights up - I don't need two lights to tell me the contactor is closed.

I want the green LED to light up whenever the PID is firing. I suppose I could just get a 12v LED and run it directly off the SSR output... But the fact remains that the setup I have _SHOULD_ be working, but it isn't, and I can't figure out why. I need the big brains of the E-Brew subforum to help me out of this one... There's a gremlin in my system and I'm not sure where.

Yes, I could run it such that the green light is on every time the contactor is closed, but I have illuminated buttons, so when I turn on the contactor the LED in the button lights up - I don't need two lights to tell me the contactor is closed.

I want the green LED to light up whenever the PID is firing. I suppose I could just get a 12v LED and run it directly off the SSR output... But the fact remains that the setup I have _SHOULD_ be working, but it isn't, and I can't figure out why. I need the big brains of the E-Brew subforum to help me out of this one... There's a gremlin in my system and I'm not sure where.

grandequeso

Well-Known Member

Put up a real close up photo of your cp. And a current diagram if you have one, shouldnt be too hard to sort out.

BadNewsBrewery

Well-Known Member

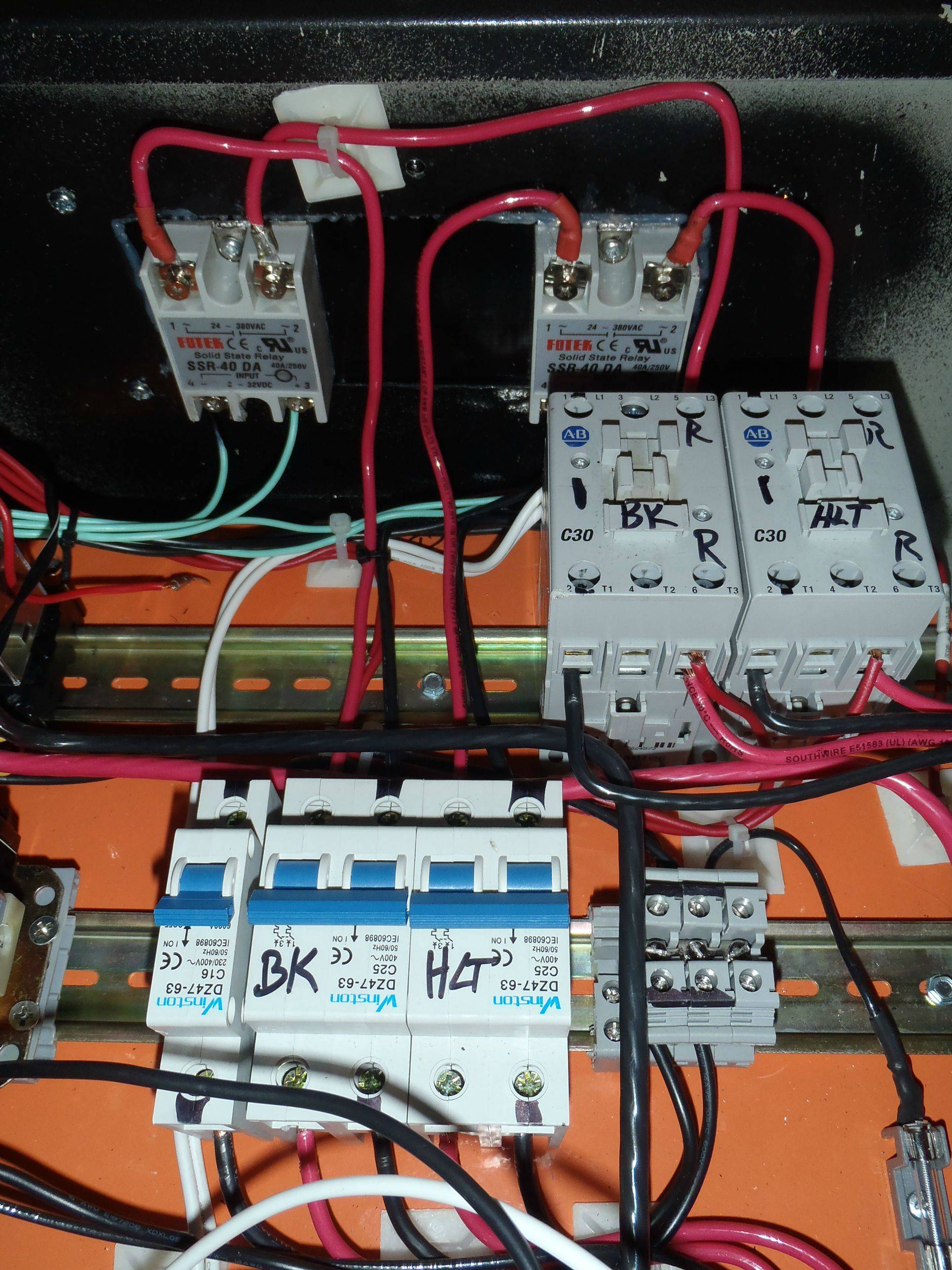

Here is the latest wiring diagram that P-J and I worked up, to reflect the switches and Safe Start Interlock.

I'll snap some photos when I get home. I snipped all the zip ties holding the wires nice and neat while trouble shooting, so it's going to be a a bit messy...

-K

I'll snap some photos when I get home. I snipped all the zip ties holding the wires nice and neat while trouble shooting, so it's going to be a a bit messy...

-K

What grandqueso said. Run them off the contactor.

With power flowing from the terminal strips -> breakers -> SSR -> contactors, it's easy to do. When the SSR closes you'll have power to the light. Just connect another line from your Hot1 and Hot2 at the contactor on the side going out to your 240v power outlets. Don't use a neutral. If they're the Auber lights they can handle 240v.

Or maybe I don't understand what you're trying to accomplish.

The plan shows an illuminated pushbutton for each element and a pilot light at the outlet.

The illuminated pushbutton let's you know the contactor is closed.

The pilot light at the outlet let's you know when the outlet is energized.

Is this not the objective?

You could always not supply power to the lamp in the pushbutton and just use the pilot light at the outlet as an indicator.

With power flowing from the terminal strips -> breakers -> SSR -> contactors, it's easy to do. When the SSR closes you'll have power to the light. Just connect another line from your Hot1 and Hot2 at the contactor on the side going out to your 240v power outlets. Don't use a neutral. If they're the Auber lights they can handle 240v.

Or maybe I don't understand what you're trying to accomplish.

The plan shows an illuminated pushbutton for each element and a pilot light at the outlet.

The illuminated pushbutton let's you know the contactor is closed.

The pilot light at the outlet let's you know when the outlet is energized.

Is this not the objective?

You could always not supply power to the lamp in the pushbutton and just use the pilot light at the outlet as an indicator.

BadNewsBrewery

Well-Known Member

stlbeer Look at my diagram - that's how I have it, that's how it's wired. The red line runs from the terminal strip -> breaker -> SSR -> contactor -> LED. The black I pulled straight off the terminal strip for wiring purposes (easier), but just for giggles I tried running it directly to the black on the contactor so it goes terminal strip -> contactor -> LED... same exact thing happened.

Don't worry about the illuminated push buttons - they work exactly as planned.

Don't worry about the illuminated push buttons - they work exactly as planned.

BadNewsBrewery

Well-Known Member

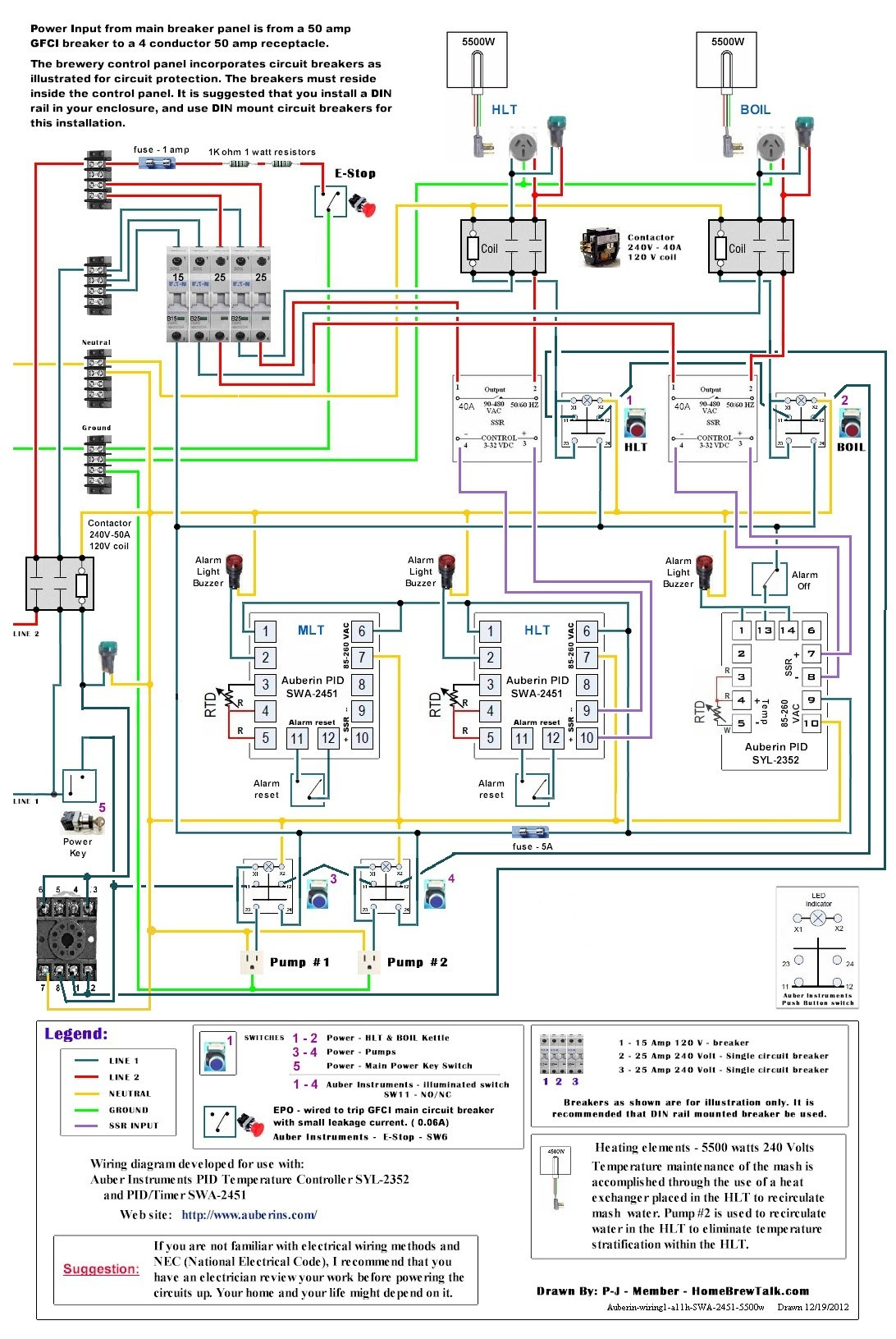

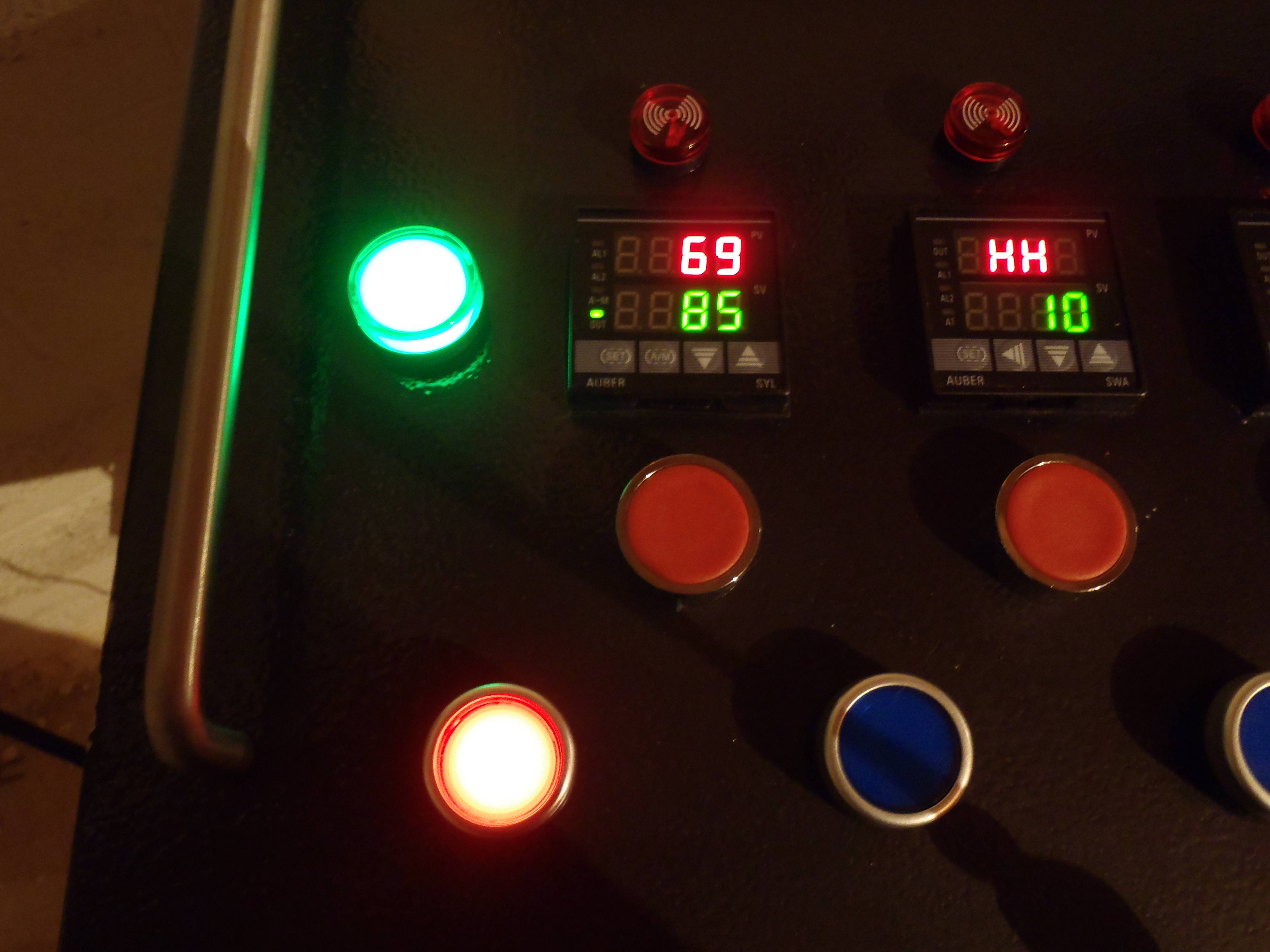

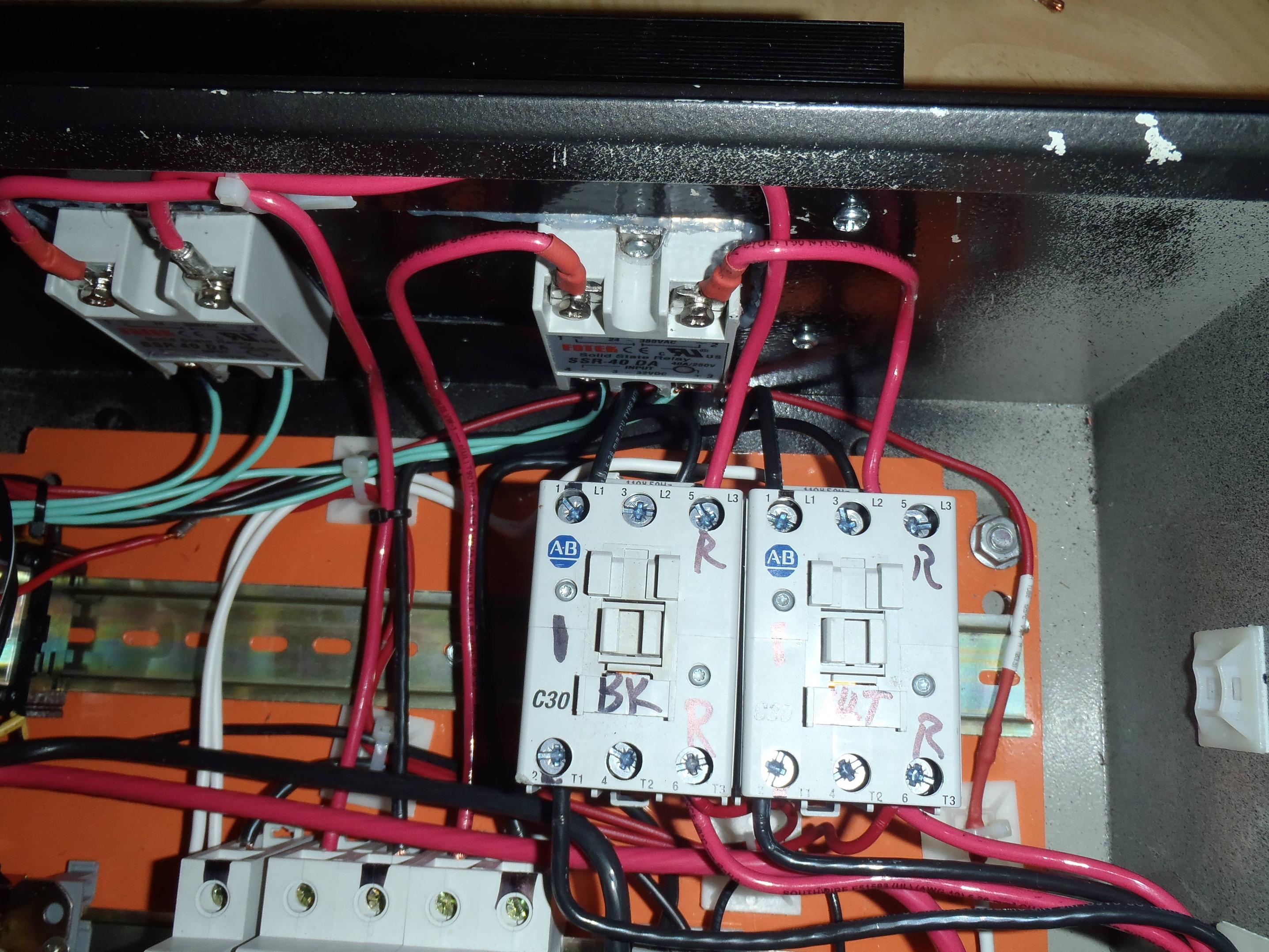

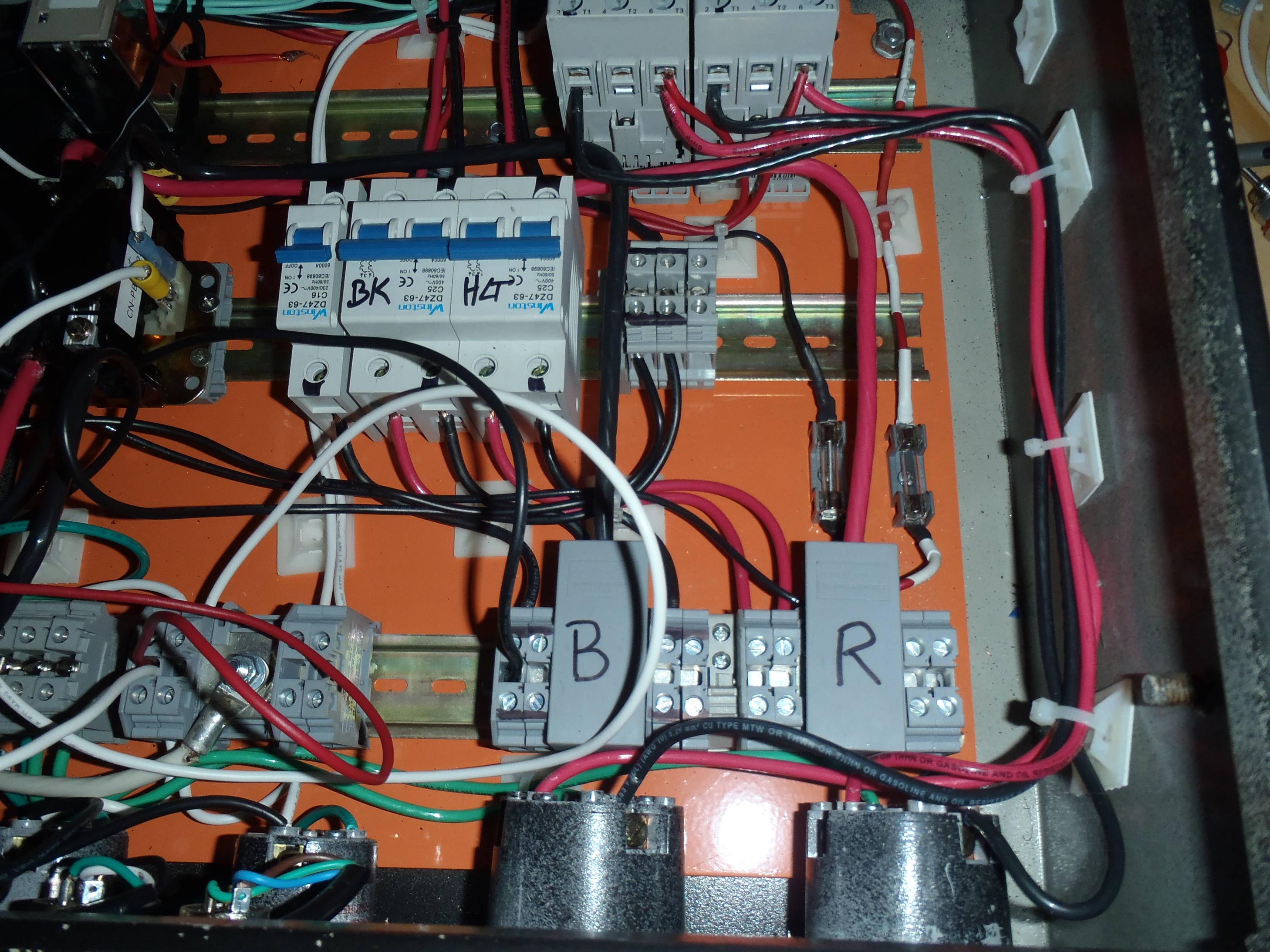

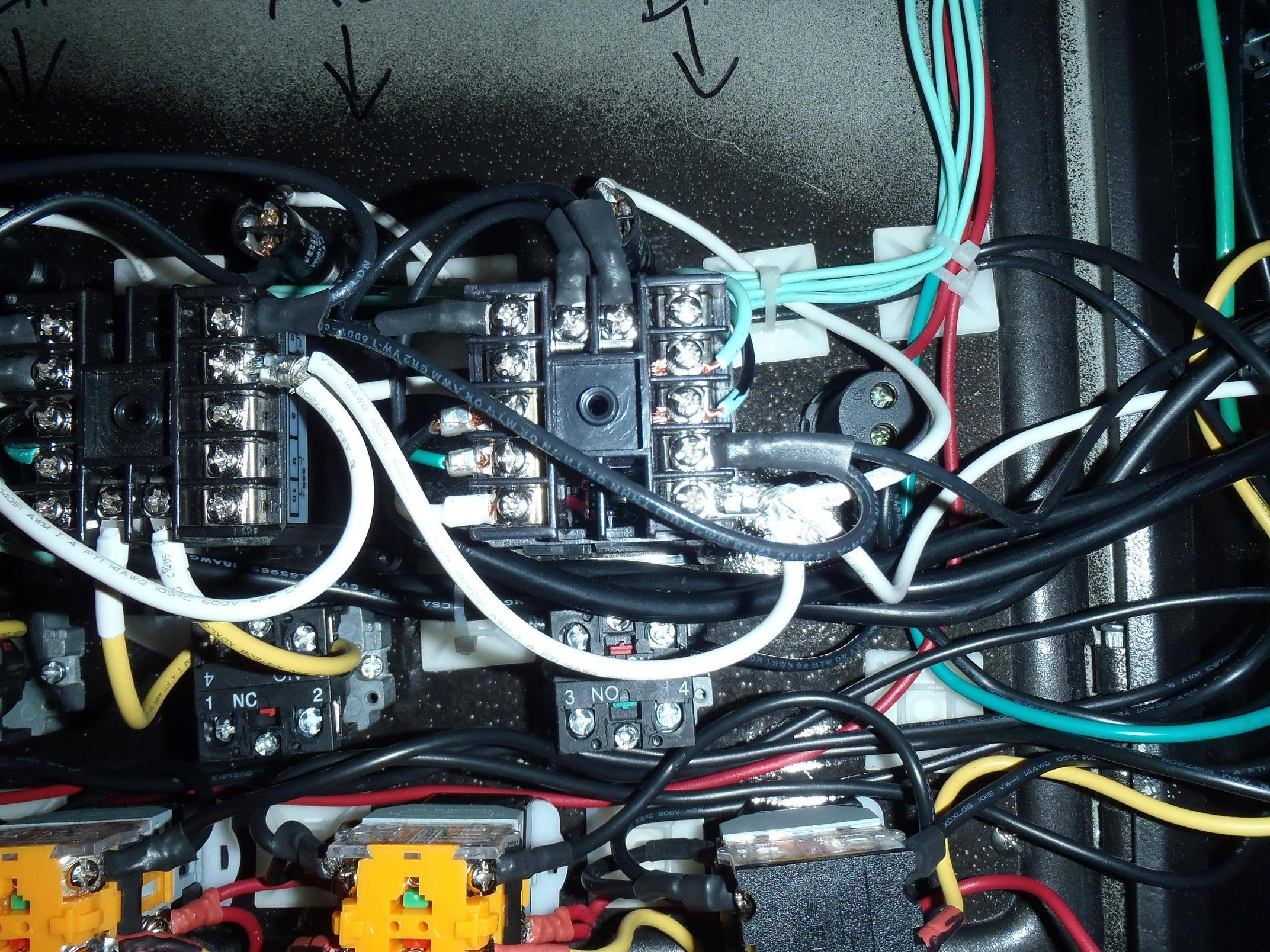

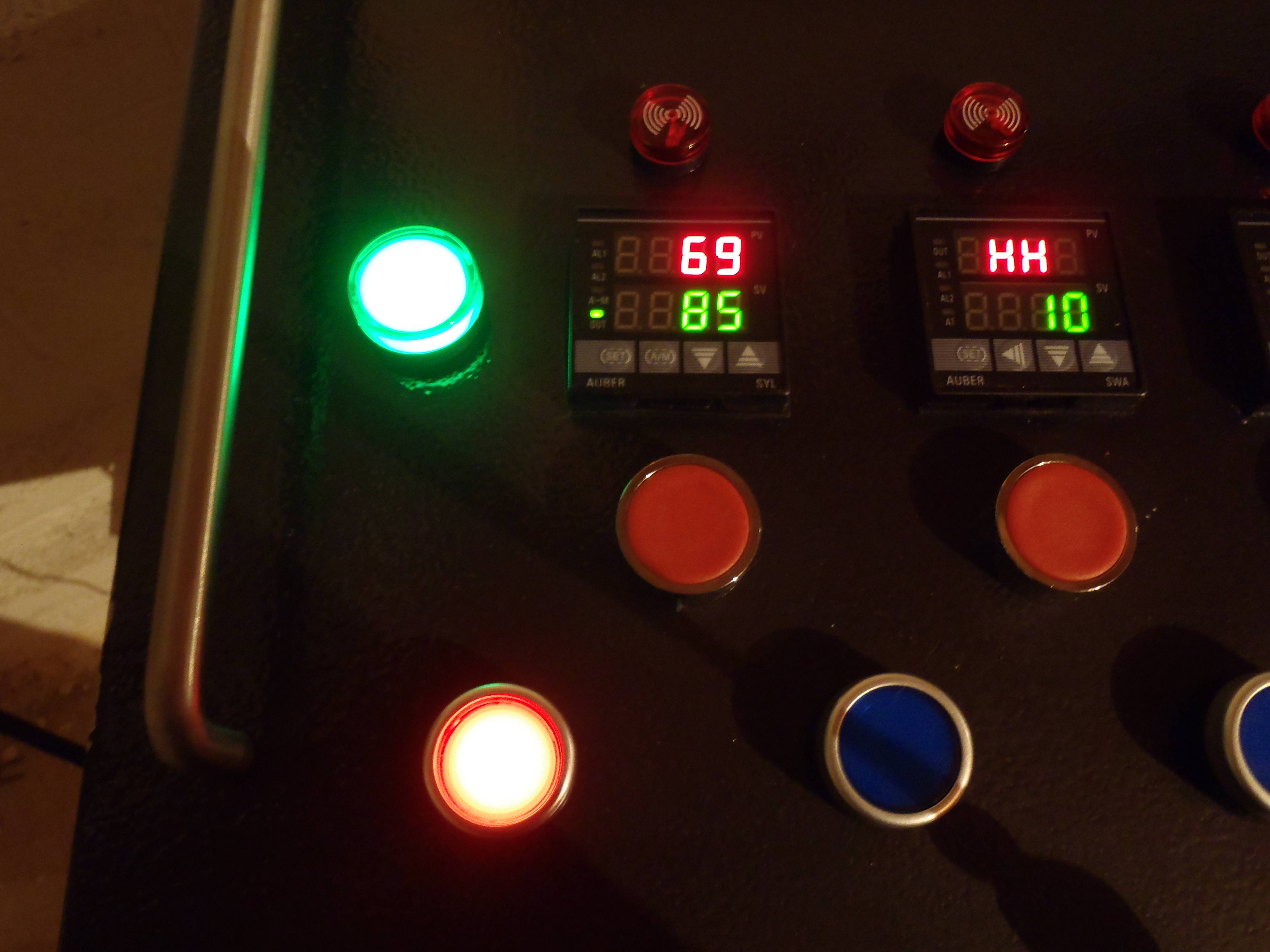

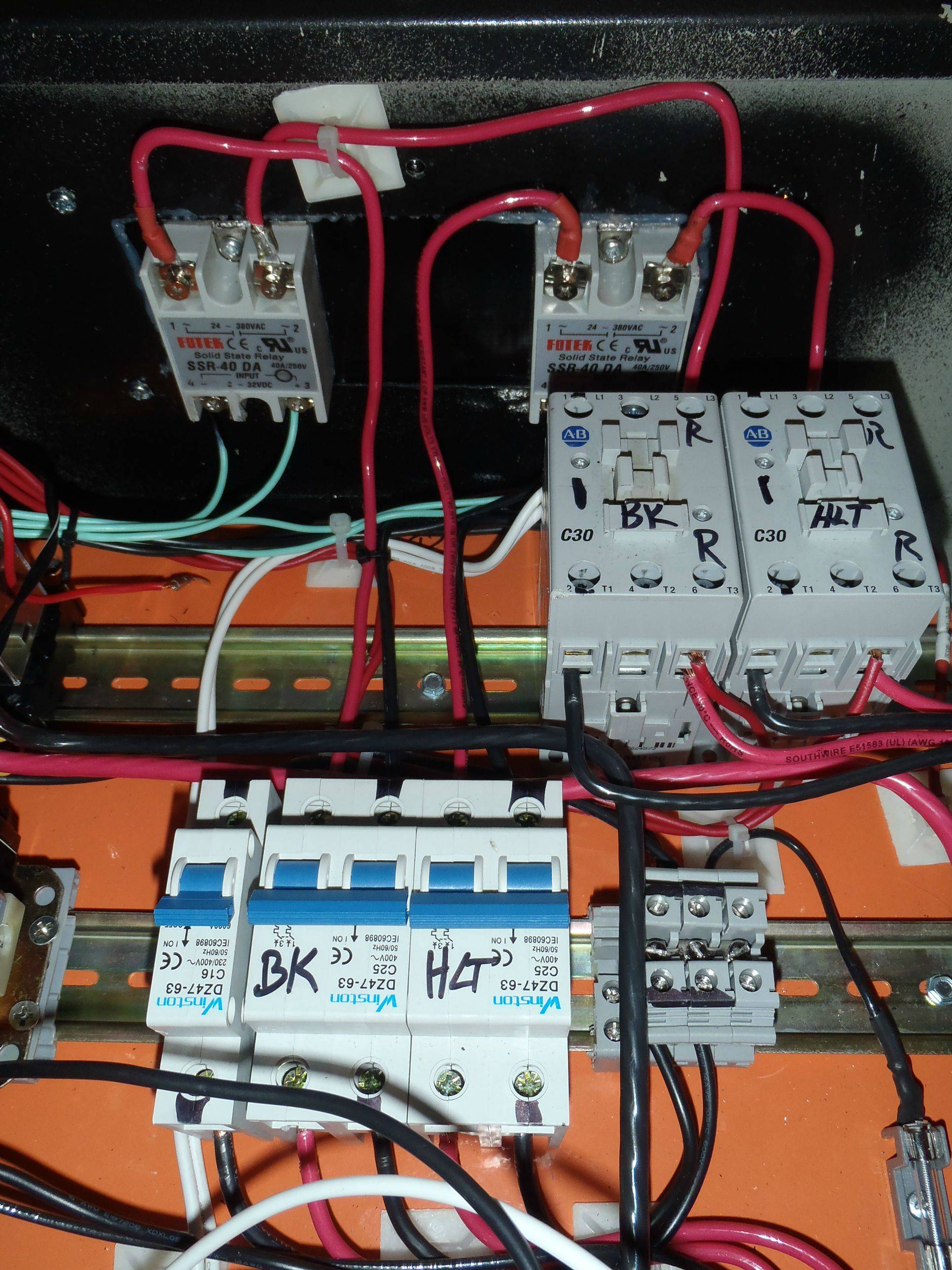

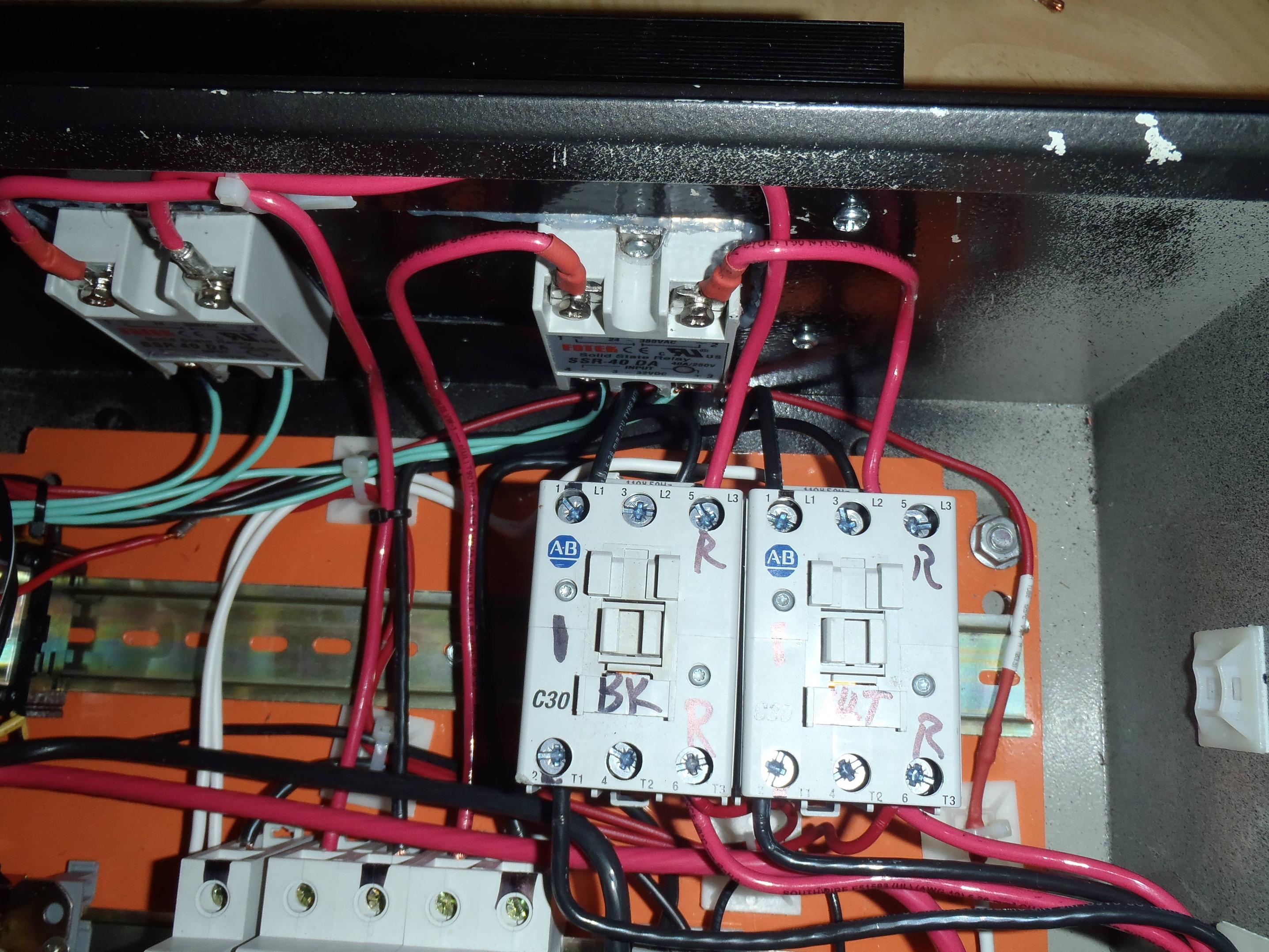

So here are some more photos.

First - a picture of the PID with the little green LED indicating that the element is being fired. The big green LED is illuminated (GOOD) and the red LED from the contactor switch is illuminated (Good).

The next image - the PID is NOT firing - no little green LED. The red LED on the contactor is still illuminated, showing that the contactor is still engaged... but the green LED next to the PID is also still on. This should NOT be happening.

So, here are some photos of the internals. The first picture is a general photo of the contactors, the SSRs, and the breaker. The previous pictures were of the BK (I don't know why, but I wanted my BK on the left, different than most). You can see the red line come from the breaker to the left input on the SSR, then from the right output of the SSR up and over to the input of the contactor. From there, two wires come out - the top 14ga red wire runs over to the LED. The bottom 10ga red goes to the plug. The black line comes out of the breaker and goes straight to the contactor.

Next is a picture of the same but looking straight down. You can see the white 14ga wire running under the black 10ga wire - that goes straight to Neutral as a home-run, and is for the coil. The 14ga black wire under the 10ga red wire goes to the switch.

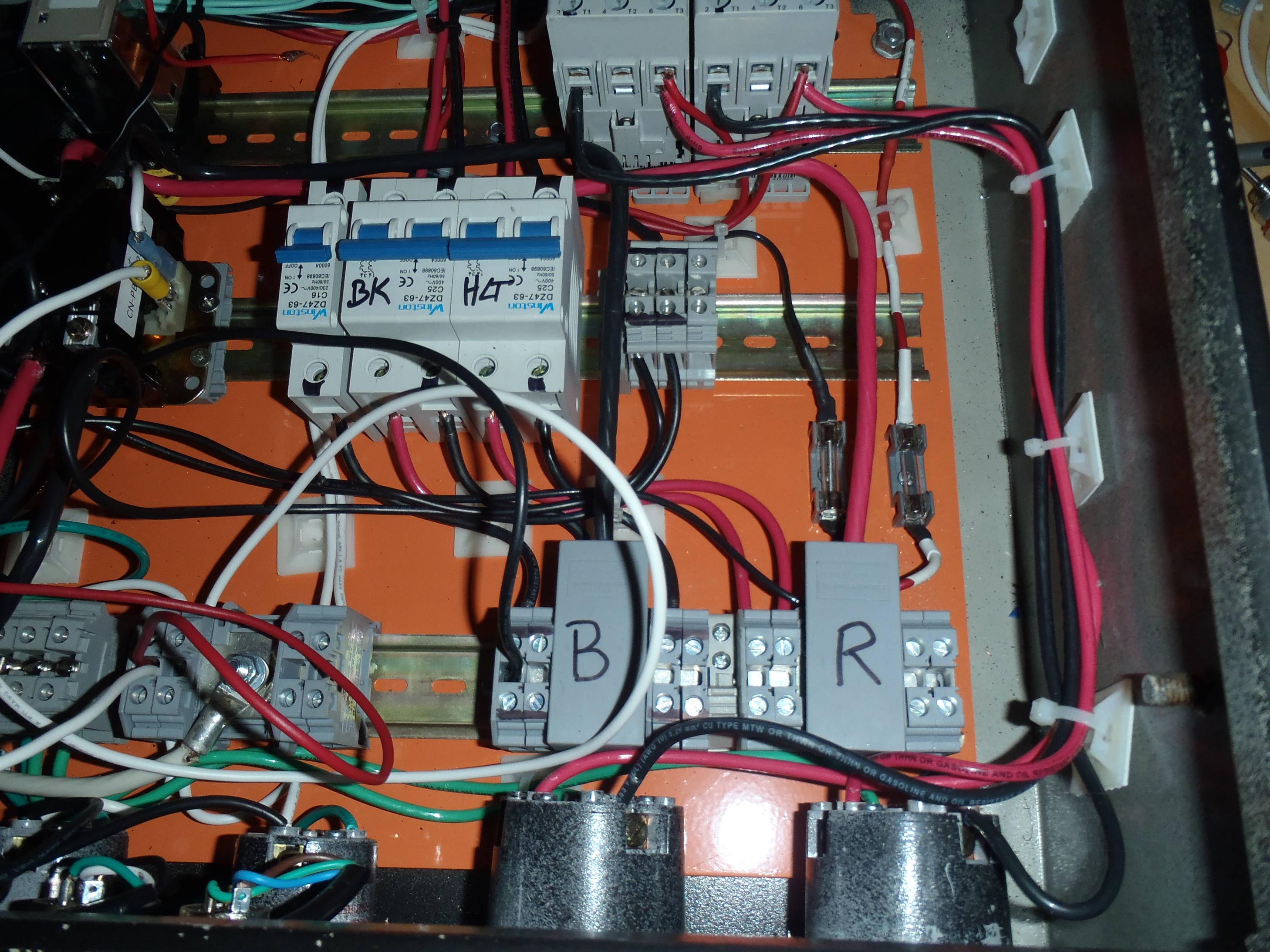

Here is a general snap of the panel area surrounding the contactors:

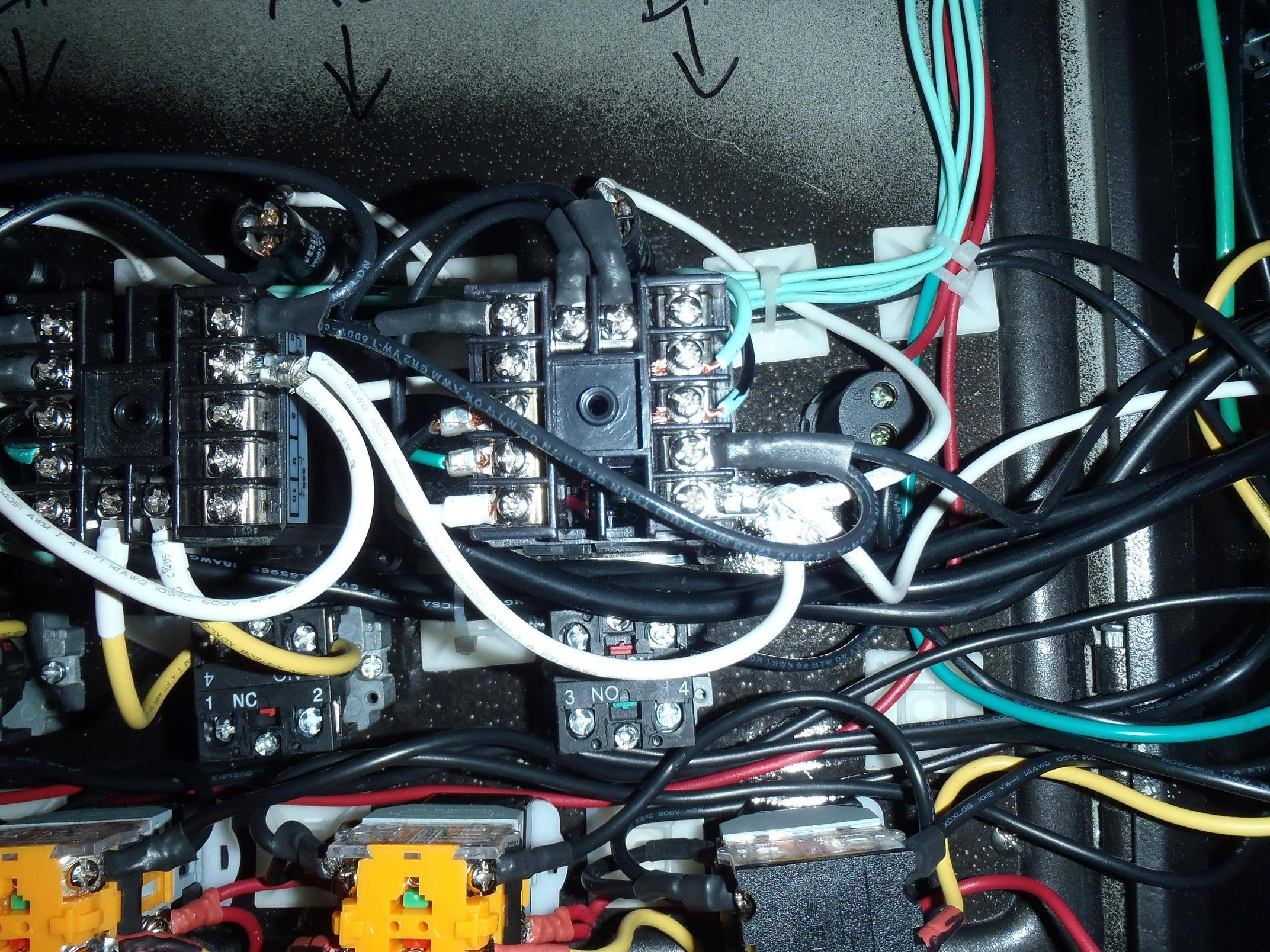

And here is a picture of the back of the PID. There's a lot going on in there, but you can see the LED to the right in the photo, with a red 14ga running to the top (that comes from the contactor) and you can kind of see a 14ga black coming out the bottom that runs to the black terminal strip.

So... what am I doing wrong?

First - a picture of the PID with the little green LED indicating that the element is being fired. The big green LED is illuminated (GOOD) and the red LED from the contactor switch is illuminated (Good).

The next image - the PID is NOT firing - no little green LED. The red LED on the contactor is still illuminated, showing that the contactor is still engaged... but the green LED next to the PID is also still on. This should NOT be happening.

So, here are some photos of the internals. The first picture is a general photo of the contactors, the SSRs, and the breaker. The previous pictures were of the BK (I don't know why, but I wanted my BK on the left, different than most). You can see the red line come from the breaker to the left input on the SSR, then from the right output of the SSR up and over to the input of the contactor. From there, two wires come out - the top 14ga red wire runs over to the LED. The bottom 10ga red goes to the plug. The black line comes out of the breaker and goes straight to the contactor.

Next is a picture of the same but looking straight down. You can see the white 14ga wire running under the black 10ga wire - that goes straight to Neutral as a home-run, and is for the coil. The 14ga black wire under the 10ga red wire goes to the switch.

Here is a general snap of the panel area surrounding the contactors:

And here is a picture of the back of the PID. There's a lot going on in there, but you can see the LED to the right in the photo, with a red 14ga running to the top (that comes from the contactor) and you can kind of see a 14ga black coming out the bottom that runs to the black terminal strip.

So... what am I doing wrong?

smittygouv30

Well-Known Member

Unfortunately I don't know how to fix your problem but I am very interested to see how this works out as I plan to wire a light in system similar to yours.

It does look like the green indicator light changes as far as brightness when the element is firing vs when it is off. Is that the case or does it just look that way in the pictures?

Corey

It does look like the green indicator light changes as far as brightness when the element is firing vs when it is off. Is that the case or does it just look that way in the pictures?

Corey

BadNewsBrewery

Well-Known Member

Honestly, some times it does look like it's different, some times not. Couldn't really say for sure.

And it does this on both SSR / contactor combos. So either I have 2 bad SSRs, 2 bad contactors, or I am going crazy.

And it does this on both SSR / contactor combos. So either I have 2 bad SSRs, 2 bad contactors, or I am going crazy.

Kevin,

I think: The SSR will pass a very small amount of leakage current when it is not told to fire the element.

The LED indicator light has a power consumption of less than 2 watts.

With 240V that means it will have a current draw of about 0.008 amps.

With that, the LED has a resistance of 30,000 ohms.

I believe there is enouh leakage current to fire the LED.

Now for something to try.

Place a 3000 ohm resistor in parallel with the indicator light. This will allow the draw of .08 amps of current and effectively shunt the indicator lights small current draw. The resistor would need to be about a 200W unit.

I think it is worth a try.

If the indicator light were a incadecent device I think it would operate as expected.

Think about it and give it a try.

Paul

I think: The SSR will pass a very small amount of leakage current when it is not told to fire the element.

The LED indicator light has a power consumption of less than 2 watts.

With 240V that means it will have a current draw of about 0.008 amps.

With that, the LED has a resistance of 30,000 ohms.

I believe there is enouh leakage current to fire the LED.

Now for something to try.

Place a 3000 ohm resistor in parallel with the indicator light. This will allow the draw of .08 amps of current and effectively shunt the indicator lights small current draw. The resistor would need to be about a 200W unit.

I think it is worth a try.

If the indicator light were a incadecent device I think it would operate as expected.

Think about it and give it a try.

Paul

BadNewsBrewery

Well-Known Member

P-J,

I'm not sure I understand. Do I need a 3000W resistor or a 200W resistor? In parallel to the LED - are you saying that I should run X1 to X2 around the LED with the resistor, or put the resistor in-line between the contactor and the LED?

-Kevin

I'm not sure I understand. Do I need a 3000W resistor or a 200W resistor? In parallel to the LED - are you saying that I should run X1 to X2 around the LED with the resistor, or put the resistor in-line between the contactor and the LED?

-Kevin

I blew it. I stated 3000W and it should have been a 3000 ohm resistor. I corrected my post.P-J,

I'm not sure I understand. Do I need a 3000W resistor or a 200W resistor? In parallel to the LED - are you saying that I should run X1 to X2 around the LED with the resistor, or put the resistor in-line between the contactor and the LED?

-Kevin

Place the resistor in parallel with the LED - not in series. This way the current flows through the LED and the resistor. The resistor will bypass some (most) of the leakage current and prevent it from illuminating.

Don't place it in line with the LED (in series).

BadNewsBrewery

Well-Known Member

jeffmeh

Well-Known Member

- Joined

- Feb 26, 2009

- Messages

- 2,145

- Reaction score

- 216

It looks like from your diagram that you have the SSR, contactor, element, and LED wired the same as Kal's. I would expect that quite a few people have it wired that way in their Kal clones, so it should work. Curious.

I was reading on some other threads about people having similar trouble, https://www.homebrewtalk.com/f170/element-light-always-ssr-leakage-288043/ is one of the threads I saw that was talking about leakage current causing similar problems

BadNewsBrewery

Well-Known Member

Wow... a lot of the explanations on that post were horrible, but I think Walker got it on this one. I have been doing all my testing with no element plugged in. I will grab an element and plug it in and if we're right it will act like the resistor P-J was talking about... and my light will be dark until the SSR fires.

If it does end up working out and all this is due to SSR leakage, then my experience should be enough evidence to anyone that an SSR alone is NOT enough. I'll do some testing tomorrow or over the weekend, maybe I'll be brewing in the Mayan after-life!

If it does end up working out and all this is due to SSR leakage, then my experience should be enough evidence to anyone that an SSR alone is NOT enough. I'll do some testing tomorrow or over the weekend, maybe I'll be brewing in the Mayan after-life!

Wow... a lot of the explanations on that post were horrible, but I think Walker got it on this one. I have been doing all my testing with no element plugged in. I will grab an element and plug it in and if we're right it will act like the resistor P-J was talking about... and my light will be dark until the SSR fires.

If it does end up working out and all this is due to SSR leakage, then my experience should be enough evidence to anyone that an SSR alone is NOT enough. I'll do some testing tomorrow or over the weekend, maybe I'll be brewing in the Mayan after-life!

BINGO.!!!

I was doing mind cramps trying to figure out what was going on. I totally forgot about the element as the "resistor" across the indicator light.

Forget about the resistor suggestion. The element is it!

I just have to say that getting really old just plain sucks.

Plug the element in (Do Not dry fire it) and test it again.

P-J

BadNewsBrewery

Well-Known Member

I had to leave for work before the sun came up, so testing the panel with an element last night / this morning was a no go. I'm anxious to get home and give it a shot. If this does work, it will solve all but the weird voltage readings I was getting. I don't want to fry my multi-meter testing for amperage as it's only rated for 10A, but part of me is thinking that the strange voltages I was picking up has something to do with inductive current from all the other wires running around. I'm willing to guess the voltage is there, but there is zero actual amperage. I suppose I could rig up a little light bulb tester to find out, but if the panel works as designed with the element plugged in, then I won't worry.

stlbeer, yes - I got the two contactors from Zeus. The terminal blocks came from Mouser, here. Part number is CDB6/2, though you can change the second number to give you more terminal blocks (remember, you can plug one in on each side, so the /2 is actually 4 connections).

stlbeer, yes - I got the two contactors from Zeus. The terminal blocks came from Mouser, here. Part number is CDB6/2, though you can change the second number to give you more terminal blocks (remember, you can plug one in on each side, so the /2 is actually 4 connections).

Similar threads

- Replies

- 14

- Views

- 1K

- Replies

- 4

- Views

- 723