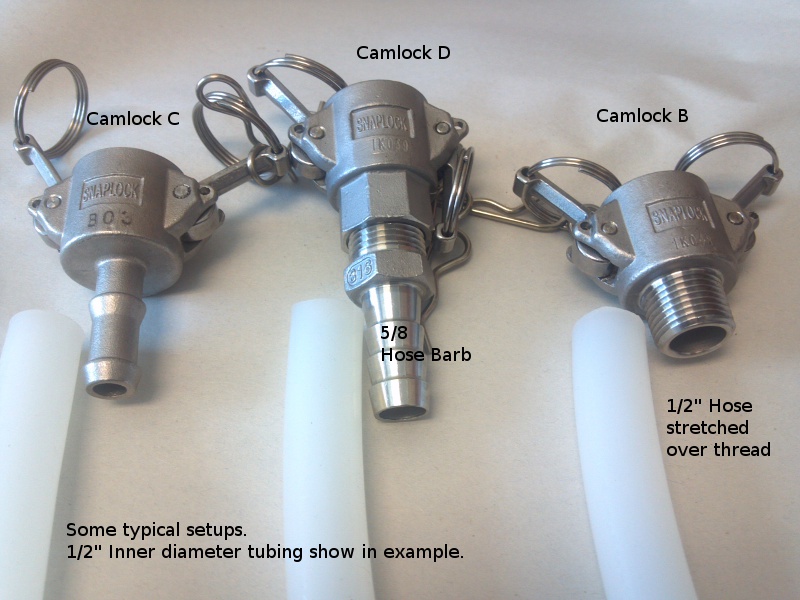

I'm about to order some fittings for all my brew equipment upgrades and have a couple of questions. Everything is 1/2", mostly male, ports. I'm trying to determine which type of quick disconnects to get, any recommendations? Tri clover? camlocks? Something else?

On the blichmann auto sparge i'm thinking of putting a T on it with ball valves on either end of that. The HLT will gravity feed into the T from the top and the pump will recirculate into the T from the bottom and I was thinking I needed ball valves on both ends of that T? Otherwise the sparge would just go down into the recirc line instead of the kettle?

I'll put a quick disconnect on the T so that I can also route the pump from the mash to the boil kettle.

Ball valves on the outputs of the pumps?

I also have a blichmann hop rocket that will be used sometimes and a plate chiller that will always be used. Also a pump to move the wort through that.

Also, what at the best clamps to secure the fittings to the 1/2" silicon tubing?

On the blichmann auto sparge i'm thinking of putting a T on it with ball valves on either end of that. The HLT will gravity feed into the T from the top and the pump will recirculate into the T from the bottom and I was thinking I needed ball valves on both ends of that T? Otherwise the sparge would just go down into the recirc line instead of the kettle?

I'll put a quick disconnect on the T so that I can also route the pump from the mash to the boil kettle.

Ball valves on the outputs of the pumps?

I also have a blichmann hop rocket that will be used sometimes and a plate chiller that will always be used. Also a pump to move the wort through that.

Also, what at the best clamps to secure the fittings to the 1/2" silicon tubing?