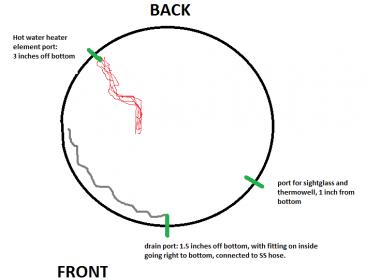

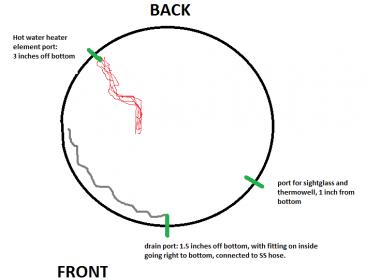

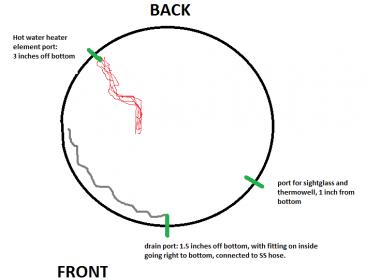

I have a standard 15.5 gal keggle. I want to generally do 10g batches but have the option of doing 5 occasionally, does this look good?

Note the brewer will be standing at the front.

Note the brewer will be standing at the front.

Enter your email address to join: