fwiw, it takes about ten minutes to convert a Barley Crusher from CW to CCW rotation of the driving roller. Here's a quicky "How To":

Remove the two screws and nuts holding the hopper and remove it. Unbolt the mill it from the base, unscrew and remove the front/back plates, wiggle the end plates apart, take the driving roller out, and flip it end-for-end before reinserting it into the end plates.

Reattach the front/back plates (but leave the screws a bit loose) and place the mill right-side-up with the handle shaft on the same side of the base as before (so the front is now the back, etc). Reattach the base (again, leave the bolts a bit loose), then attach the handle crank. Rotate the crank slowly, looking for any "hitching" that would indicate misaligned bearings, then press down on all four plates so they are flat to the base, and start snugging up the screws for the front/back plates and the two mounting bolts until they're all tight and the crank moves freely. If the crank develops a "hitch", loosen everything up and try again.

Thanks,

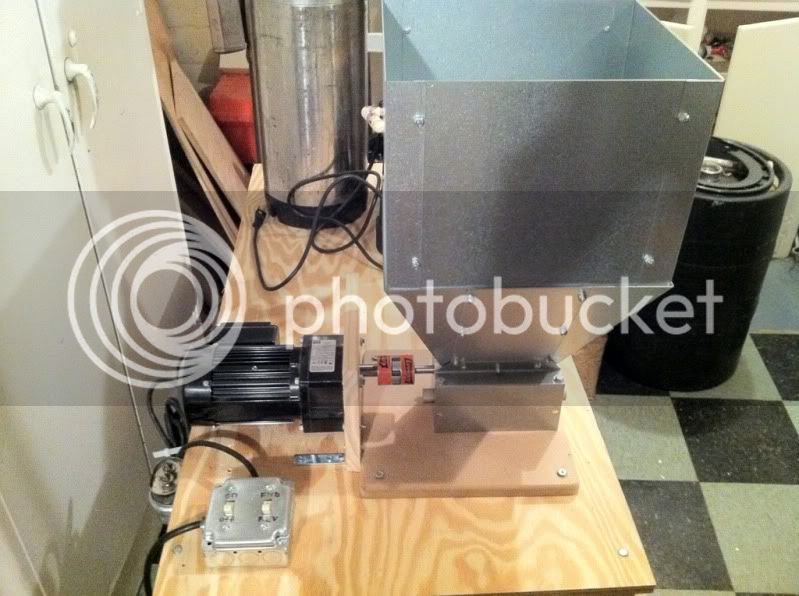

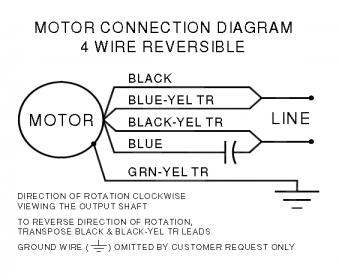

P-J, for the information on the (very popular) 5-1098 gear motor. I was about to design my grinding station/cabinet so your post was very timely! While many have had no problems running it in reverse (CW) with Barley Crushers, I prefer optimal operation over just being lucky

Cheers!