Brewpastor

Beer, not rocket chemistry

I have been working on my brewing rig for over five years and have put together some images of my up-dated set-up. I recognize that I will never be finished with this project, but why would I want to be?!

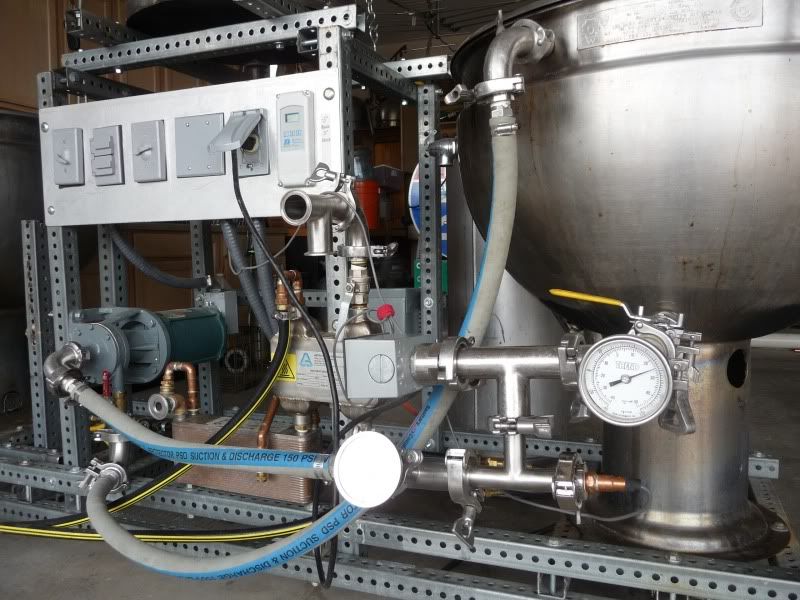

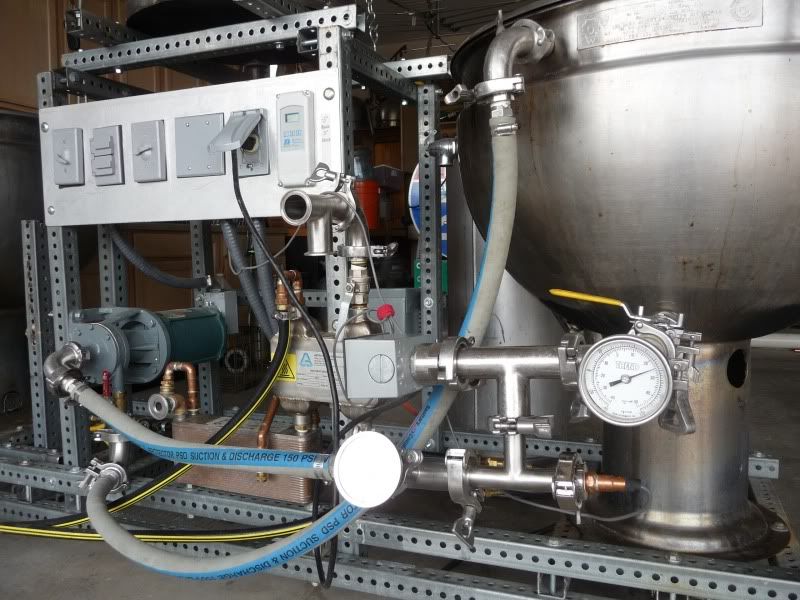

Stripped Down Rig:

This is my modified rig stripped down for storage. By stripped down I mean it has no fittings of valves attached. The black and yellow hoses are glycol lines attached to the second zone of my chiller.

The main changes are the electrical set-up, including a thermostatically controlled plug. It also contains a general use plug and the switch for my pump. I have moved all my mashing into the smaller kettle on the right and installed a tri-clover in-let near the top for various uses such as sparging. The center vessel, which previously was used as a mash tun/whirlpool, is now the hot liquor tank. I made this switch because I like a heated mash tun and the new HLT heats more quickly and easily. It also doubles as a great CIP (clean in place) unit.

Mash/Lauter Tun:

This vessel is 40 gallons and steam jacketed. The false bottom is a Blichmann 20 gallon false bottom. It is secured to the kettle by a stainless bolt attached to a removable outlet sleeve. The image here shows the Fly Sparge ring attached. I also have fittings for Batch Sparging and RIM recirculation.

Recirculation Infusion Mash Set-up:

The Mash/Lauter Tun is steam jacketed and very easily adjusted to any given mash temperature. Additionally, a Recirculation Infusion Mash unit is utilized for holding mash temperatures. The RIM unit consists of an inline water heater element which plugs into an outlet wired into a Ranco digital controller. The controller’s thermo-coupler is located in an inline thermo-well.

(continued)

Stripped Down Rig:

This is my modified rig stripped down for storage. By stripped down I mean it has no fittings of valves attached. The black and yellow hoses are glycol lines attached to the second zone of my chiller.

The main changes are the electrical set-up, including a thermostatically controlled plug. It also contains a general use plug and the switch for my pump. I have moved all my mashing into the smaller kettle on the right and installed a tri-clover in-let near the top for various uses such as sparging. The center vessel, which previously was used as a mash tun/whirlpool, is now the hot liquor tank. I made this switch because I like a heated mash tun and the new HLT heats more quickly and easily. It also doubles as a great CIP (clean in place) unit.

Mash/Lauter Tun:

This vessel is 40 gallons and steam jacketed. The false bottom is a Blichmann 20 gallon false bottom. It is secured to the kettle by a stainless bolt attached to a removable outlet sleeve. The image here shows the Fly Sparge ring attached. I also have fittings for Batch Sparging and RIM recirculation.

Recirculation Infusion Mash Set-up:

The Mash/Lauter Tun is steam jacketed and very easily adjusted to any given mash temperature. Additionally, a Recirculation Infusion Mash unit is utilized for holding mash temperatures. The RIM unit consists of an inline water heater element which plugs into an outlet wired into a Ranco digital controller. The controller’s thermo-coupler is located in an inline thermo-well.

(continued)