Kay. Post one was for the gunners at the front of the classroom. Hopefully Kaiser and wortmonger will handle you guys' questions. All I know is this thing is

really cool.

For the folks on the short bus with me:

A spunding valve holds a fermenter at a particular pressure. So you could (and I can w00t! w00t!) ferment and carbonate at the same time. So your beer is ready sooner. So if your round ball team makes the NCAA after all you are looking at 3 weeks grains to glass instead of 6 weeks.

I bought this stuff because of wortmonger's thread here:

https://www.homebrewtalk.com/showthread.php?t=44344

I just finished updating my brew house. Rather then go big on the hot side I decided to clean up the cold side first. Real hard to develop an infection in something boiling, lots of awards for folks who primary in stainless.

So I ditched all the plastic, ditched all the glass. I am running a 5gal SS kettle, five 5gal SS cornies, and I got a plastic bottling bucket if I need to bottle something.

So with the spunding valve I transfer from primary to secondary to serving keg without having to stand there twiddling my thumbs, and my risk of contamination is very low. Plus I get the 3 weeks grain to glass thing...

So, standard "line" in my new brew house, 9.5 feet of 3/16" ID:

For the calibration runs coming I put a black connector on each end.

Here is the top view of the setup you are about to see. No, I am not quitting my day job. "S" means source, T is target and C is the red tripod my camera was resting on for this.:

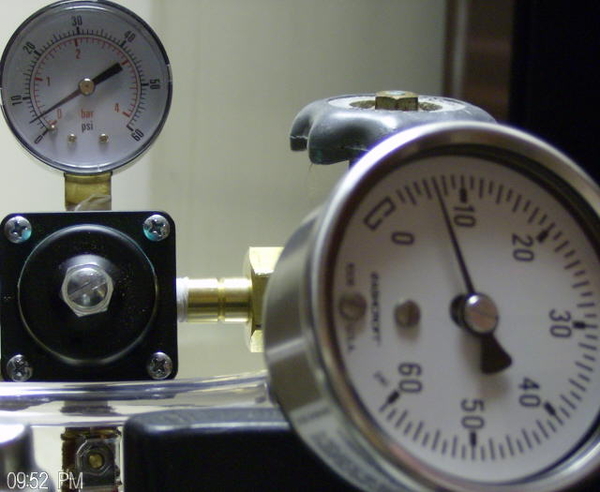

Finally, here is a view of the two pressure gages actually in focus:

I think I am about to run out of image tags per post...