I've been brewing on-and-off for the past 7 years, and continuously for the past 4. Every beer i've made has fermented in my utility room, which is partially underground. Unfortunately, this room also houses my washer/dryer, which means that the temperature can fluctuate a bit. A bucket of water usually reads anywhere from 68-72 year round, so for a while I thought everything was within reasonable margins.

Point is, most of my beers were fine. My "house strain" is London Ale III, which I think is great for pale ales, IPA's... pretty much anything where the yeast doesn't play a huge role. I always had trouble with any beer using German Ale yeasts, or Hefe yeasts, etc. because of the combination of fluctuating temperatures and being on the high side of the temperature range. So after 4 years in my town house, I decided it was time to build a fermentation chamber so that I wouldn't have to worry anymore about my inconsistent / slightly high temps. Here's the build!

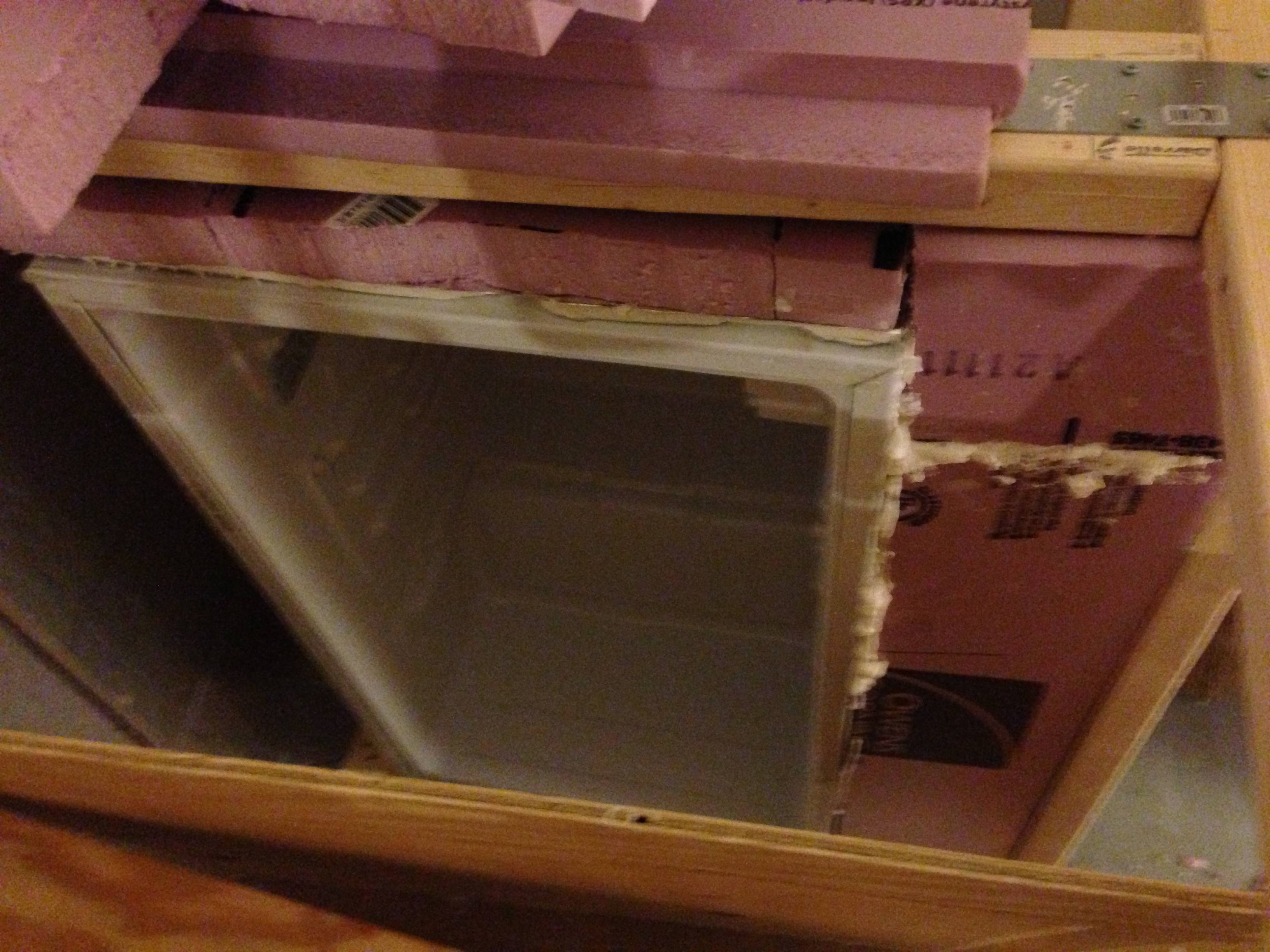

This is the base. I based (heh) my build on that of stratslinger's build: https://www.homebrewtalk.com/f51/another-fermentation-chamber-build-253949/

I should've used something cheaper to attach the 2x4's to each other, but I'm not so handy so I didn't know the cheapest option. Stratslinger used a pocket hole jig (and his work was beautiful!) but I'm easily swayed... so when i found out that my local Home Depot was no longer carrying pocket hole jigs, I decided to do it this way. I also have the mending plates on the other side of the base, because with only one side it wasn't nearly sturdy enough. Honestly I can't remember why I used the weather stripping between the base and the bottom layer (the side pictured is actually the bottom side).

The main difference in my design and his is that I decided to make my chamber bigger than the outline of the fridge - so big, in fact, that I can easily fit 4 buckets/carboys in there, possibly more (depending on configuration). Anyway. The base is 58" x 33". The posts have a height of 33" as well, giving the entire box a 36" height (not counting the casters I put it on).

Point is, most of my beers were fine. My "house strain" is London Ale III, which I think is great for pale ales, IPA's... pretty much anything where the yeast doesn't play a huge role. I always had trouble with any beer using German Ale yeasts, or Hefe yeasts, etc. because of the combination of fluctuating temperatures and being on the high side of the temperature range. So after 4 years in my town house, I decided it was time to build a fermentation chamber so that I wouldn't have to worry anymore about my inconsistent / slightly high temps. Here's the build!

This is the base. I based (heh) my build on that of stratslinger's build: https://www.homebrewtalk.com/f51/another-fermentation-chamber-build-253949/

I should've used something cheaper to attach the 2x4's to each other, but I'm not so handy so I didn't know the cheapest option. Stratslinger used a pocket hole jig (and his work was beautiful!) but I'm easily swayed... so when i found out that my local Home Depot was no longer carrying pocket hole jigs, I decided to do it this way. I also have the mending plates on the other side of the base, because with only one side it wasn't nearly sturdy enough. Honestly I can't remember why I used the weather stripping between the base and the bottom layer (the side pictured is actually the bottom side).

The main difference in my design and his is that I decided to make my chamber bigger than the outline of the fridge - so big, in fact, that I can easily fit 4 buckets/carboys in there, possibly more (depending on configuration). Anyway. The base is 58" x 33". The posts have a height of 33" as well, giving the entire box a 36" height (not counting the casters I put it on).

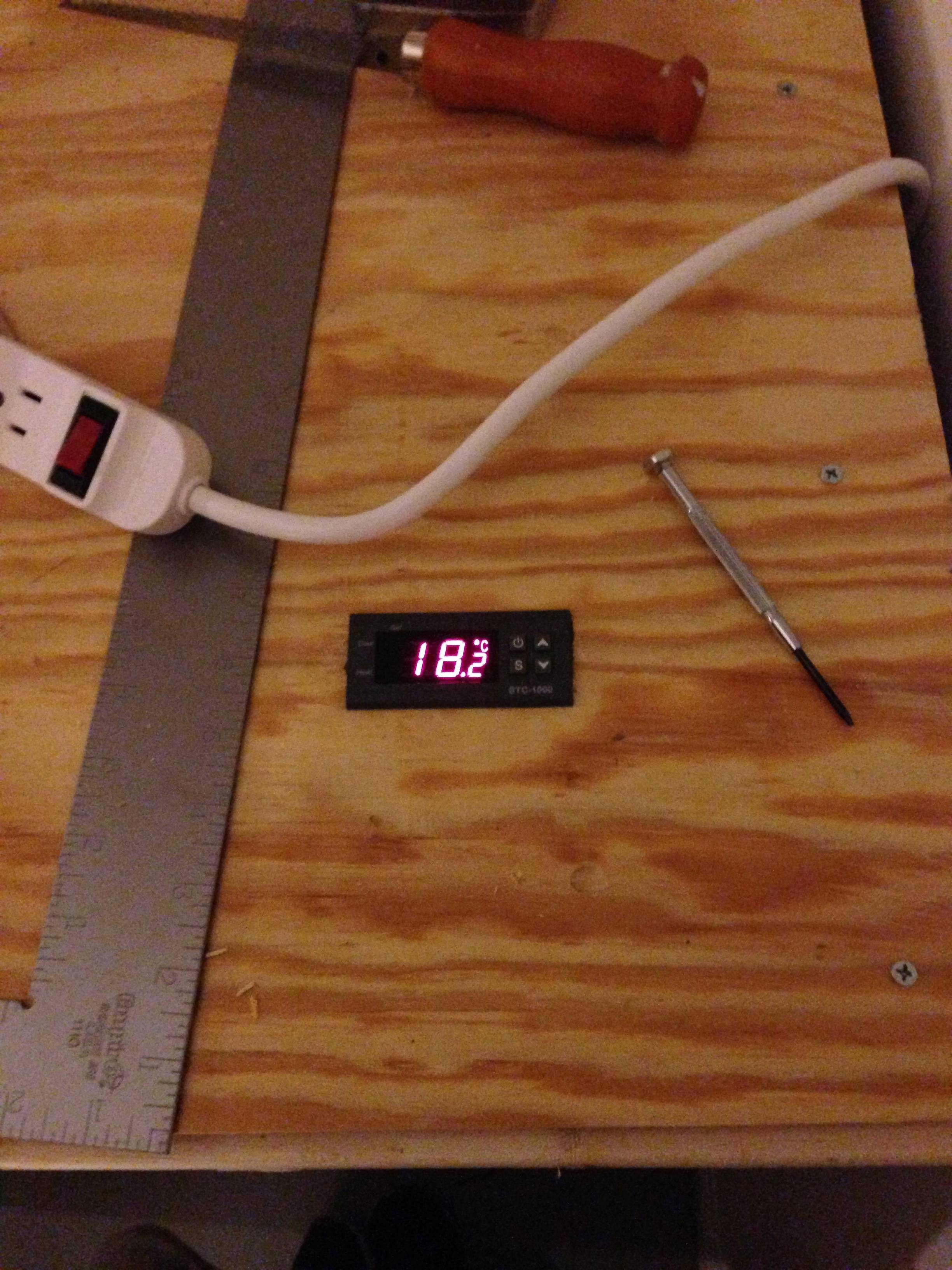

so I might just leave it as is. Here you go!

so I might just leave it as is. Here you go!