bagpiperjosh

Well-Known Member

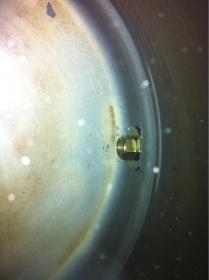

i looked but didnt finda thread on it. I'd like to make my own weldless site glass for my keggles.. anyone know of a how-to and parts list? id like to buy everything at Home Depot or Lowes if i can.

If i HAVE to buy them , i'd buy from Bobby M because ive heard nothing but good things. but id rather make them myself if possible, because thats just more fun to me.

thanks!

If i HAVE to buy them , i'd buy from Bobby M because ive heard nothing but good things. but id rather make them myself if possible, because thats just more fun to me.

thanks!