You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anyone steam-mashing?

- Thread starter el_loco

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

slarkin712

Well-Known Member

Here's a thread that almost got me to try it:

https://www.homebrewtalk.com/f51/easy-steam-infusion-mash-system-25974/

I have a much bigger pressure cooker and I didn't want to modify it, otherwise I think it's a great idea.

https://www.homebrewtalk.com/f51/easy-steam-infusion-mash-system-25974/

I have a much bigger pressure cooker and I didn't want to modify it, otherwise I think it's a great idea.

Bensiff

Well-Known Member

- Joined

- Mar 13, 2008

- Messages

- 4,835

- Reaction score

- 411

I remember that thread too. I got into reading about proper steam systems and the safety mechanisms involved and quickly came to the conclusion that it may not be a safe path to modify a pressure cooker without proper safety precautions and since I don't know any steam engineers to help me out I gave up on the idea. I figure electric brewing has much more knowledge behind it with plenty of electrical engineers being involved in design process, and my neighbor is an electrician so it was the safer path for me.

...I got into reading about proper steam systems and the safety mechanisms involved and quickly came to the conclusion that it may not be a safe path to modify a pressure cooker without proper safety precautions and since I don't know any steam engineers to help me out I gave up on the idea...

Fair enough, but without evidence this is really just conjecture. We are only dealing with 15 lbs of pressure MAYBE. Adding a valve to a commercially designed pressure cooker seems pretty safe to me. As long as you don't alter the safety release and do a decent job of affixing the valve there's really no reason to be concerned about accidents, especially at such low pressures.

StMarcos

Well-Known Member

You guys are mixing up two totally different ideas. Steam injection mashing is a way to use atmospheric pressure steam, bubbled through the mash, to perform step mashing. You do add a very small amount of water in the process that you should account for. The reason that some use pressure cookers is because they have a sealed lid, allowing for easier connection to a tube to run into the mash. There is no pressure beyond atmospheric. This can be a very nice way to perform step mashing if you're using a plastic MT.

Many breweries boil using steam at a bit below 15psi. The steam boiler also has a connection to the mash tun to heat it up as well. In these circumstances the steam transfers energy through a wall, not directly into the mash or wort.

Many breweries boil using steam at a bit below 15psi. The steam boiler also has a connection to the mash tun to heat it up as well. In these circumstances the steam transfers energy through a wall, not directly into the mash or wort.

I'm no physicist, but the pressure cooker prevents water from boiling at 212 (or equivalent) by keeping it under pressure and in doing holds the stored energy. This energy would normally be released at standard atmospheric pressures. When the valve opens the steam rushes out as a result of the pressure difference between the atmosphere and the inside of the pressure cooker so in a sense: Yes, we are only using steam at standard pressures. It's that the water is being held at above normal atmosphere by an altered tool that freaks some folks out. But bottom line: A pressure cooker is designed to heat water to 240 degrees, above it's boiling point, and you CAN'T do that at standard atmospheric pressure. I believe you are mistaken in your understanding.

StMarcos's is mostly correct. I believe he is saying that you do not have to operate the pressure cooker at a higher pressure (it of course is safer not too). The lid is just a convenient way to funnel the steam to the mash tun.

With a pressure cooker, you just take the little weight off and connect the steam line to the stem. The weight is what regulates the amount of pressure generated (at least on old school/inexpensive models). You might get some pressure generated just because of the tubing length and the weight of the mash.

It would be no different than putting a regular pot on the stove and drilling a hole in the lid, and inserting a nipple to connect a steam line to. (Well a little different as the lid on a regular pot would allow some steam to escape)

One could add a valve to give some back pressure, and that would result in hotter steam for faster stepping

With a pressure cooker, you just take the little weight off and connect the steam line to the stem. The weight is what regulates the amount of pressure generated (at least on old school/inexpensive models). You might get some pressure generated just because of the tubing length and the weight of the mash.

It would be no different than putting a regular pot on the stove and drilling a hole in the lid, and inserting a nipple to connect a steam line to. (Well a little different as the lid on a regular pot would allow some steam to escape)

One could add a valve to give some back pressure, and that would result in hotter steam for faster stepping

Bensiff

Well-Known Member

- Joined

- Mar 13, 2008

- Messages

- 4,835

- Reaction score

- 411

Fair enough, but without evidence this is really just conjecture. We are only dealing with 15 lbs of pressure MAYBE. Adding a valve to a commercially designed pressure cooker seems pretty safe to me. As long as you don't alter the safety release and do a decent job of affixing the valve there's really no reason to be concerned about accidents, especially at such low pressures.

15psi is nothing to sneeze at especially considering that it is playing with superheated steam that would be rapidly expanding and burning anyone nearby if anything went wrong in the system. My reasoning is this, pressure cookers were designed for a specific purpose, by adding a valve and hose onto them you change the dynamics of the system. The biggest issue I saw was that when you open the valve to inject steam you run the risk of causing a pressure drop which if enough could result in a rapid vaporization in the boiler which can cause a boil over. If that occurs the safety valve can get clogged with water and not function momentarily which in turn can spike pressure which if that exceeds anything in the system you can have a blow out. Perhaps a minor inconvenience of it blowing your mash all over the place or worse, the hose next to your body rupturing.

With such concerns and the desire to build an automated system that I could comfortably walk away from, this made me think that a much more robust steam system was in order which was out of my knowledge base and ability to fund. I would love to see someone build a solid steam system though as I am fully sold on the superiority of steam.

Bensiff

Well-Known Member

- Joined

- Mar 13, 2008

- Messages

- 4,835

- Reaction score

- 411

StMarcos's is mostly correct. I believe he is saying that you do not have to operate the pressure cooker at a higher pressure (it of course is safer not too). The lid is just a convenient way to funnel the steam to the mash tun.

With a pressure cooker, you just take the little weight off and connect the steam line to the stem. The weight is what regulates the amount of pressure generated (at least on old school/inexpensive models). You might get some pressure generated just because of the tubing length and the weight of the mash.

It would be no different than putting a regular pot on the stove and drilling a hole in the lid, and inserting a nipple to connect a steam line to. (Well a little different as the lid on a regular pot would allow some steam to escape)

One could add a valve to give some back pressure, and that would result in hotter steam for faster stepping

Saturated steam is only 212 degrees so you would need a lot of steam to raise the systems temperature, that is why you need superheated steam as it holds way more energy and you can feasibly raise the temperature of a mash with a relatively small boiler.

Good discussion so far fellas. I am aware of how a pressure cooker works and the concept behind using it to heat the mash. I would like to hear what peoples experience has been who've actually done it. If there have been any mishaps or injuries or whether those fears are just overactive imagination (which is a very valuable tool, don't get me wrong!). But empirical evidence is missing and I want to have some.

Bensiff

Well-Known Member

- Joined

- Mar 13, 2008

- Messages

- 4,835

- Reaction score

- 411

Good discussion so far fellas. I am aware of how a pressure cooker works and the concept behind using it to heat the mash. I would like to hear what peoples experience has been who've actually done it. If there have been any mishaps or injuries or whether those fears are just overactive imagination (which is a very valuable tool, don't get me wrong!). But empirical evidence is missing and I want to have some.

Unfortunately I don't have hands on experience, I really like the idea of using steam but that empirical evidence you are looking for (Boyles law) pushed me away from the pressure cooker idea. I hope someone does say something though, especially someone who has figured out a good safety system...steam burns hurt like hell and scare me (if you can't tell).

StMarcos

Well-Known Member

But you're not supposed to operate it under pressure. Maybe a psi from the mash height. The 'pressure' cooker is no longer a pressure cooker, because you've vented the port into a tube that is open to the mash.

From:

http://www.artisan-distiller.net/phpBB3/viewtopic.php?f=11&t=1044&hilit=steam+mashing&start=15

From:

http://www.artisan-distiller.net/phpBB3/viewtopic.php?f=11&t=1044&hilit=steam+mashing&start=15

StMarcos

Well-Known Member

Saturated steam is only 212 degrees so you would need a lot of steam to raise the systems temperature, that is why you need superheated steam as it holds way more energy and you can feasibly raise the temperature of a mash with a relatively small boiler.

The energy comes mostly from the phase change, not the temperature change of the water/steam.

Steam can be saturated at other temperatures if the pressure is changed.

Super heated steam is heated to a temperature above it's equilibrium with boiling water at whatever pressure you're talking about. For instance, you'd have to put a heater in the path of the steam to superheat that steam.

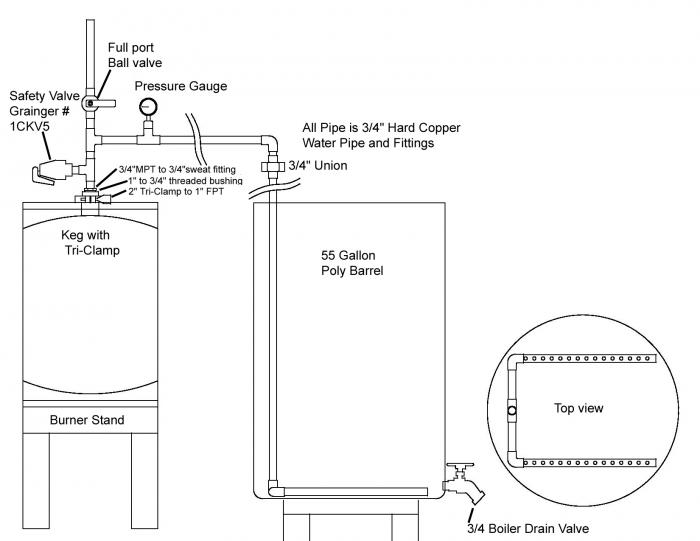

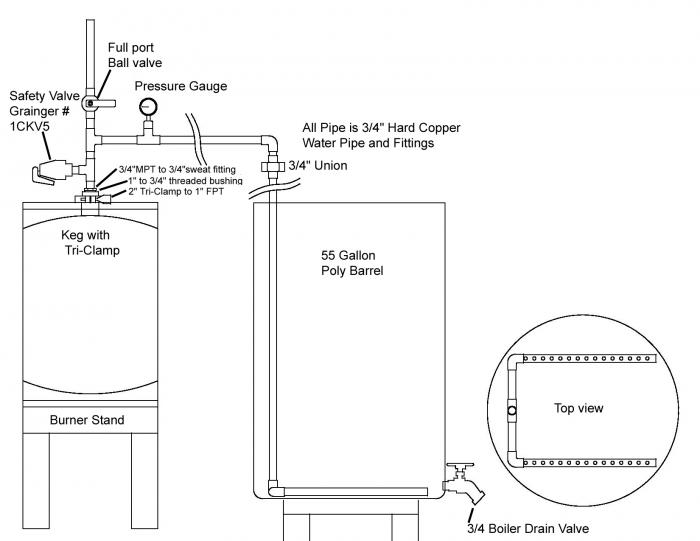

I use steam all the time. My boiler is a 1/2 barrel stainless keg operated at 12 psi and about 240 degrees F. I can provide more details later (currently using my phone). For now, read here for info on pressure cooker based systems:

https://www.homebrewtalk.com/f51/easy-steam-infusion-mash-system-25974/

https://www.homebrewtalk.com/f51/easy-steam-infusion-mash-system-25974/

StMarcos

Well-Known Member

Please do yuri. Also interested in the delivery of the steam to the boil kettle or mash tun, whatever you do, in addition to the generation source. Thx!

I modified a Sanke keg to include a 5500W element and threaded fittings. There is a fill/drain valve near the bottom, and a 1/2" stainless fitting at the top where I installed a tee with a ball valve for steam, a 20 psi blow-off valve, and a small barb for pressure sensing via a small diameter silicone tube. I also installed a thermowell and temperature sensor.

The system is controlled via a Dallas one-wire system connected to a Linux computer running scripts that I wrote. It's very basic - when it senses less than 10 psi, the element turns on via solid state relays. When the pressure exceeds 12 psi, the element is switched off. The temperature hovers around 240 degrees F, but I do not use temperature as a control input.

I manually control the steam output with a ball valve. If I want to heat the mash, I dunk a length of stainless tubing (rudimentary nozzle) connected to the silicone outlet hose on the boiler and open the ball valve. Stirring is required to keep the heat even. It's very effective at maintaining mash temp in an uninsulated 20 gallon stainless kettle (15 gallon all grain batches).

There is a side inlet on the stainless tube for cold water. I use it for sparging. Simply connect a water hose to the steam "nozzle," crack the valve for a steady stream of fresh water, and adjust the steam flow to achieve sparge temps.

When I'm done using steam for mashing/sparging, I turn off the heating element, put the nozzle into the boil kettle, and open the valve, allowing any remaining steam energy to accelerate getting the wort to a boil. Later, I use the remaining hot water for cleaning - it stays HOT for hours.

Future upgrades include:

A hollow mixing paddle with holes throughout to directly inject steam while stirring, preferable motorized

A "mixing" screen inside the sparge nozzle at the point where fresh water meets steam - turbulence is the key to avoid popping and spitting where hot meets cold

MAYBE automated temp control. The more I brew, the less I'm interested in full automation. I find that I want to be involved in the process, and that I have to monitor everything closely, regardless of the level of automation. A hands-on approach seems fitting.

I can't, in good conscience, recommend that anyone copy my system. I modified a pressure vessel and routinely apply heat to it, generating a ridiculous amount of steam energy. It's downright dangerous. I have pressure tested the system and I am confident in my control scheme and backup safety measures (safety valve), but I would feel AWFUL if someone got hurt (killed) attempting to copy it. Additionally, no one should need 10+ gallons of water for steam generation in a homebrewery. I find that I use only 2-3 gallons of water in the boiler for an entire 1/2 bbl brew day, even when things don't go well. I'm strongly considering downsizing.

Instead, I recommend going the pressure cooker route. Adding an outlet valve to an existing pressure cooker that already has a means by which to regulate internal pressure seems far safer. Also, the volume of water/steam/energy stored is far less.

The system is controlled via a Dallas one-wire system connected to a Linux computer running scripts that I wrote. It's very basic - when it senses less than 10 psi, the element turns on via solid state relays. When the pressure exceeds 12 psi, the element is switched off. The temperature hovers around 240 degrees F, but I do not use temperature as a control input.

I manually control the steam output with a ball valve. If I want to heat the mash, I dunk a length of stainless tubing (rudimentary nozzle) connected to the silicone outlet hose on the boiler and open the ball valve. Stirring is required to keep the heat even. It's very effective at maintaining mash temp in an uninsulated 20 gallon stainless kettle (15 gallon all grain batches).

There is a side inlet on the stainless tube for cold water. I use it for sparging. Simply connect a water hose to the steam "nozzle," crack the valve for a steady stream of fresh water, and adjust the steam flow to achieve sparge temps.

When I'm done using steam for mashing/sparging, I turn off the heating element, put the nozzle into the boil kettle, and open the valve, allowing any remaining steam energy to accelerate getting the wort to a boil. Later, I use the remaining hot water for cleaning - it stays HOT for hours.

Future upgrades include:

A hollow mixing paddle with holes throughout to directly inject steam while stirring, preferable motorized

A "mixing" screen inside the sparge nozzle at the point where fresh water meets steam - turbulence is the key to avoid popping and spitting where hot meets cold

MAYBE automated temp control. The more I brew, the less I'm interested in full automation. I find that I want to be involved in the process, and that I have to monitor everything closely, regardless of the level of automation. A hands-on approach seems fitting.

I can't, in good conscience, recommend that anyone copy my system. I modified a pressure vessel and routinely apply heat to it, generating a ridiculous amount of steam energy. It's downright dangerous. I have pressure tested the system and I am confident in my control scheme and backup safety measures (safety valve), but I would feel AWFUL if someone got hurt (killed) attempting to copy it. Additionally, no one should need 10+ gallons of water for steam generation in a homebrewery. I find that I use only 2-3 gallons of water in the boiler for an entire 1/2 bbl brew day, even when things don't go well. I'm strongly considering downsizing.

Instead, I recommend going the pressure cooker route. Adding an outlet valve to an existing pressure cooker that already has a means by which to regulate internal pressure seems far safer. Also, the volume of water/steam/energy stored is far less.

StMarcos

Well-Known Member

Thanks for that. What do you see as the advantage to controlling based on the pressure rather than temperature for the boiler heater? Aren't pressure sensors more liable to get fouled and not be as stable as, say, a good quality RTD?

If you feel fine maintaining 10-12psi in your system, what would be your hesitations with using that steam source to power an indirect, calandria/coil type input to the boil kettle? Of course it's not needed, but say you wanted to give it a go for fun/intrigue, what might you do to return the condensate back to the boiler? I've some thoughts, but not anything more advanced than an engineer 150 years ago pondering the same question. Home-welded jackets might take some considerable research to assuage fears of rupture, but a coil/calandria with inch-ish diameter tubing would seem to me to be well within the abilities of many DIY-ers on this forum. For example, welding a homemade sanke keg from scratch, able to safely hold 60psi, would be much more tricky than some 3/4'' copper sweat fittings that would easily hold 60psi for decades/indefinitely. The sanke keg has a much larger diameter compared to the copper tube. Ignore the material differences for this thought experiment....

If you feel fine maintaining 10-12psi in your system, what would be your hesitations with using that steam source to power an indirect, calandria/coil type input to the boil kettle? Of course it's not needed, but say you wanted to give it a go for fun/intrigue, what might you do to return the condensate back to the boiler? I've some thoughts, but not anything more advanced than an engineer 150 years ago pondering the same question. Home-welded jackets might take some considerable research to assuage fears of rupture, but a coil/calandria with inch-ish diameter tubing would seem to me to be well within the abilities of many DIY-ers on this forum. For example, welding a homemade sanke keg from scratch, able to safely hold 60psi, would be much more tricky than some 3/4'' copper sweat fittings that would easily hold 60psi for decades/indefinitely. The sanke keg has a much larger diameter compared to the copper tube. Ignore the material differences for this thought experiment....

StMarcos

Well-Known Member

Coils like so:

I guess that these kettles are large enough that the surface area of a jacket might not be large enough to deliver enough power. That and the copper internals might not stand up to a jacket at 15psi.

I guess that these kettles are large enough that the surface area of a jacket might not be large enough to deliver enough power. That and the copper internals might not stand up to a jacket at 15psi.

StMarcos-

I believe the advantages of using steam under pressure are lost in an internal coiled system. A high temp pump circulating boiling water through coils in the MLT (sort of like HERMS) would probably serve that type of setup better. As far as a system using steam through coils to heat a boil kettle, well now we are moving away from the original question and the content I was hoping to gather here, so perhaps that is a discussion for a new thread? I'm only interested in the basic idea of using a pressure cooker to hold water under low volumes of pressure as a source of convenient heat to step-mash in a cooler MLT. I'd like to learn more about that in this thread.

Yuri- I'm so glad you are contributing to this thread, thank you! While I was initially considering using steam for step-mashing, your original build thread along with Fly Guy's experimental build thread were the two I was most inspired by. I have no intentions of building a steam system like yours, but rather just a basic pressure cooker and valve. It seems that people have all different ideas about doing this, from confusion about whether there's any pressurization involved to the possibility of explosions. I was hoping a veteran of steam step-mashing could provide some history of use pointers.

There is inherent danger when using a pressure cooker for step-mashing in this way, but it doesn't seem likely to be an issue with the lower pressures and small volumes we are discussing. Also I've never HEARD of a brewer who uses a pressure cooker having a problem, rather I've heard that it MIGHT be a problem from brewers who don't do it. I'm more interested in empirical evidence from folks that are experienced with pressure-cooker systems, but there only seems to be a handful of them on HBT.

I believe the advantages of using steam under pressure are lost in an internal coiled system. A high temp pump circulating boiling water through coils in the MLT (sort of like HERMS) would probably serve that type of setup better. As far as a system using steam through coils to heat a boil kettle, well now we are moving away from the original question and the content I was hoping to gather here, so perhaps that is a discussion for a new thread? I'm only interested in the basic idea of using a pressure cooker to hold water under low volumes of pressure as a source of convenient heat to step-mash in a cooler MLT. I'd like to learn more about that in this thread.

Yuri- I'm so glad you are contributing to this thread, thank you! While I was initially considering using steam for step-mashing, your original build thread along with Fly Guy's experimental build thread were the two I was most inspired by. I have no intentions of building a steam system like yours, but rather just a basic pressure cooker and valve. It seems that people have all different ideas about doing this, from confusion about whether there's any pressurization involved to the possibility of explosions. I was hoping a veteran of steam step-mashing could provide some history of use pointers.

There is inherent danger when using a pressure cooker for step-mashing in this way, but it doesn't seem likely to be an issue with the lower pressures and small volumes we are discussing. Also I've never HEARD of a brewer who uses a pressure cooker having a problem, rather I've heard that it MIGHT be a problem from brewers who don't do it. I'm more interested in empirical evidence from folks that are experienced with pressure-cooker systems, but there only seems to be a handful of them on HBT.

How about a "double boiler setup?"

Steam from underneath, Natural nearly the sparging temperature in a "contained kettle" and the steam-juice escapes out the bottom. Two temperature probes, one in the mash one in the kettle. While mashing out you'd be concerned with the grain temps, not the water in the bottom.. so you'd need two controllers, or a rtd and switches to choose between them.

I have been "bag brewing" but think top double boiler would be better.. just a idea thou, not proven out yet. ONE kettle.. easy, less to clean, more production for less input. At the worst you would have to irrigate the top pot, put a stainless float switch in the lid to stop overflows.. BUT seeing some of the complicated 3 kettle systems, this would be minor hardware and inconvenience.

The stainless float cost me like $4 off ebay. Digital output, not a current rated thou.

I am also interested in Plotting "heat curves" in the mash, boil pots to achieve a more consistent result. For some reason, the 1500, would not achieve the proper boil temps test I did was better than the 4200 watt high speed heat rise beer..

I'm still learning, point me in the right way. The electrical controls I can figure out.

StMarcos

Well-Known Member

Sorry, got a bit ahead of myself. I think if you have some redundancy in the safety mechanism on the pressure cooker and/or line to the MT, you can feel confident that nothing will go wrong. If you can securely attach a tube to the PC then you're 90% of the way there.

The ratio of water's latent heat to it's heat capacity is about 500. So if you boil off a litre of water and condense it in your MT, you can raise 500L one degree C, or 50L 10degC, etc.... ratio is actually 567.

The ratio of water's latent heat to it's heat capacity is about 500. So if you boil off a litre of water and condense it in your MT, you can raise 500L one degree C, or 50L 10degC, etc.... ratio is actually 567.

I use pressure as the control input for a couple of reasons:

Pressure, not temperature is most likely to cause the system to fail. I mitigate risk by controlling the parameter that has the most potential to cause harm.

My pressure sensor provides nearly instantaneous feedback as pressure changes and has a very high resolution across a small scale (0-20 psi, relative). My temperature sensor takes time to normalize as temperature changes (on the order of at least 10 seconds and perhaps as long as a minute, depending on the rate of change). It also measures at a lower resolution across a much broader scale, and there is a fair amount of installation error to do conduction to the thermowell from the boiler walls. So, pressure is a much more accurate measurement for my system.

To address a few other concepts here:

Steam coils are an interesting concept, but I don't think they'd be very effective, especially on a small scale, for the reasons stated above. If coils are your thing, you could make a flash boiler by directly heating a coil through which water is passed. I've seen several HBTers use that concept to great effect (kladue to name one). A flash boiler is potentially safer, since it is an open system and heat is only applied when steam is desired.

A jacketed kettle would be AWESOME, but the fabrication required is pretty intense. To keep things simple, square seams would likely be used, which would be extremely weak in a pressure vessel. There are commercially available steam kettles, but they are almost always either very expensive or used and completely unserviceable.

Pressure, not temperature is most likely to cause the system to fail. I mitigate risk by controlling the parameter that has the most potential to cause harm.

My pressure sensor provides nearly instantaneous feedback as pressure changes and has a very high resolution across a small scale (0-20 psi, relative). My temperature sensor takes time to normalize as temperature changes (on the order of at least 10 seconds and perhaps as long as a minute, depending on the rate of change). It also measures at a lower resolution across a much broader scale, and there is a fair amount of installation error to do conduction to the thermowell from the boiler walls. So, pressure is a much more accurate measurement for my system.

To address a few other concepts here:

Steam coils are an interesting concept, but I don't think they'd be very effective, especially on a small scale, for the reasons stated above. If coils are your thing, you could make a flash boiler by directly heating a coil through which water is passed. I've seen several HBTers use that concept to great effect (kladue to name one). A flash boiler is potentially safer, since it is an open system and heat is only applied when steam is desired.

A jacketed kettle would be AWESOME, but the fabrication required is pretty intense. To keep things simple, square seams would likely be used, which would be extremely weak in a pressure vessel. There are commercially available steam kettles, but they are almost always either very expensive or used and completely unserviceable.

There is nothing really unsafe about using the pressure cooker as a steam generator and injecting steam into the mash AS LONG AS YOU DON'T DISABLE THE RELIEF VALVE.

Whether the pressure cooker holds all its water or some of it is lost to the mash tun makes the pressure cooker no difference. The only thing I warn against is putting one on a super hot burner. They were designed for stove top use. They were not designed to be put over a 100K BTU propane burner. I worry about localized hot spots and metalurgical issues with the cooker when using a big burner.

Yes, steam will scald you. Just as fire will burn you and electricity will fry. There are dangers inherent in every heat source. Pick your poison.

I'm in the process of building a new brewstand. I am strongly considering using steam.

https://www.homebrewtalk.com/f51/birth-zeus-non-typical-brewstand-build-368010/index11.html

Whether the pressure cooker holds all its water or some of it is lost to the mash tun makes the pressure cooker no difference. The only thing I warn against is putting one on a super hot burner. They were designed for stove top use. They were not designed to be put over a 100K BTU propane burner. I worry about localized hot spots and metalurgical issues with the cooker when using a big burner.

Yes, steam will scald you. Just as fire will burn you and electricity will fry. There are dangers inherent in every heat source. Pick your poison.

I'm in the process of building a new brewstand. I am strongly considering using steam.

https://www.homebrewtalk.com/f51/birth-zeus-non-typical-brewstand-build-368010/index11.html

I think this video is very illustrative of the potential for steam injection for heating the mash and for boiling.

Note the design of their injectors. They condense 90% of the steam before it reaches the water. Apparently those injectors are very high power and the steam used in this video is pretty low pressure.

The only thing I don't like about using steam injection for boiling is that the wort isn't going to be reduced in volume as it boils. The water in the steam that adds to the boil kettle will replace the water that is getting boiled off. One would need a jacketed kettle or an immersion coil for that. Which is doable as well.

Note the design of their injectors. They condense 90% of the steam before it reaches the water. Apparently those injectors are very high power and the steam used in this video is pretty low pressure.

The only thing I don't like about using steam injection for boiling is that the wort isn't going to be reduced in volume as it boils. The water in the steam that adds to the boil kettle will replace the water that is getting boiled off. One would need a jacketed kettle or an immersion coil for that. Which is doable as well.

Last edited by a moderator:

Similar threads

- Replies

- 2

- Views

- 218

- Replies

- 34

- Views

- 952

- Replies

- 29

- Views

- 944