scottvin

Well-Known Member

Do I have a leak?

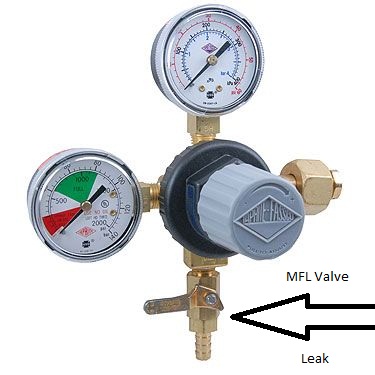

I have my C02 tank in the fridge along with the kegs. When I open the lid to my fridge, I am smelling (or feeling) that sensation you get when you open your primary fermenter for the first time. The burning sensation - which I asusme is C02. The keg has been hooked up to the C02 for 14 days. If I turn the C02 valve off, then turn it back on in the morning, I hear the gas rushing into the keg for about 15 seconds. Is this normal?

How tight should I screw the poppets on? I tried to test it with spraying starsan on all the contact points put I didn't see any bubbles. Any ideas? Thanks!

I have my C02 tank in the fridge along with the kegs. When I open the lid to my fridge, I am smelling (or feeling) that sensation you get when you open your primary fermenter for the first time. The burning sensation - which I asusme is C02. The keg has been hooked up to the C02 for 14 days. If I turn the C02 valve off, then turn it back on in the morning, I hear the gas rushing into the keg for about 15 seconds. Is this normal?

How tight should I screw the poppets on? I tried to test it with spraying starsan on all the contact points put I didn't see any bubbles. Any ideas? Thanks!