Hello, HBT! This is my first post on this site, but certainly not my first visit.

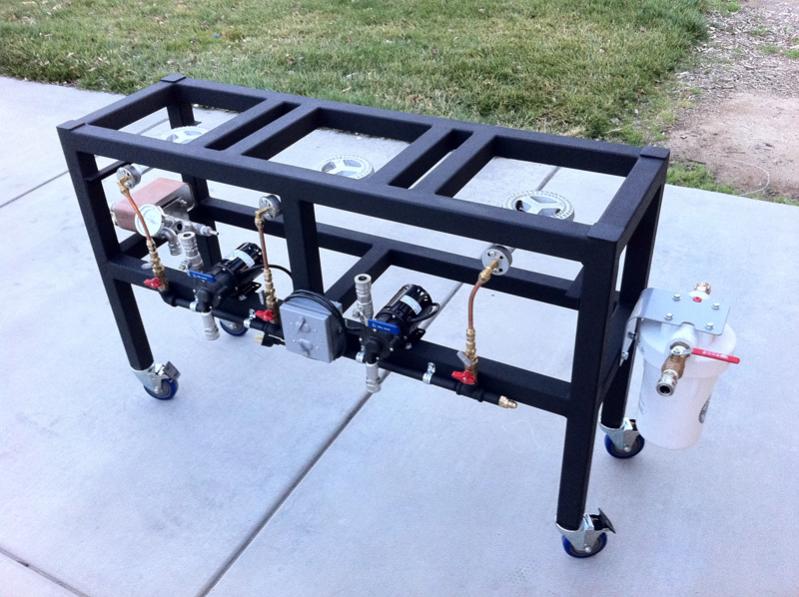

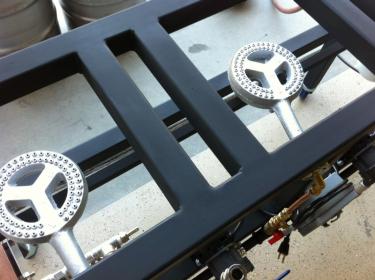

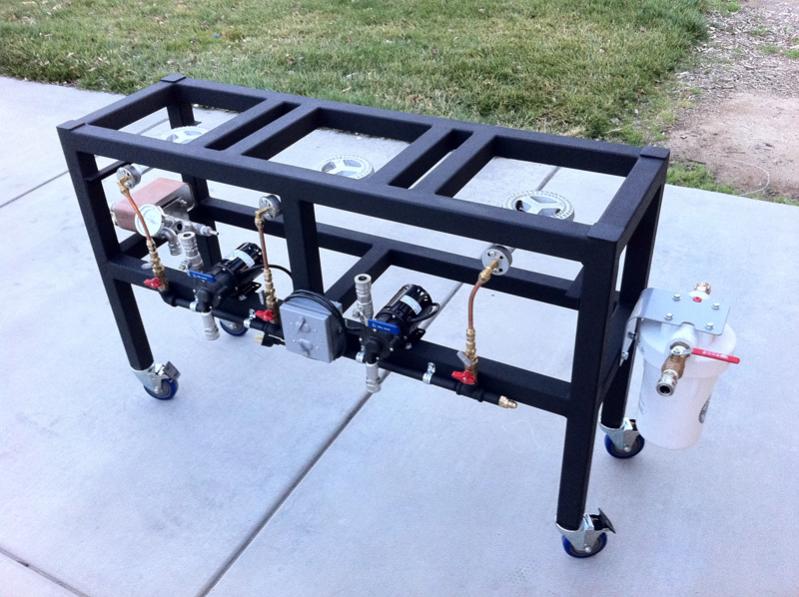

I recently completed my build of a Brutus 10 "clone", minus the fancy electronicsit's all manually controlled. I wanted to post a photo of said brewing stand and say THANK YOU to EVERYONE that posts/posted on this site for the endless knowledge and needed insight that you all unknowingly provided to me throughout this build. It took me a little over a month to build the stand. Because of the knowledge provided here, I really think I made a quality, safe, kick-ass brewing stand.

I plan on taking more photos this week, and I'll post them when they're complete.

Again, thank you very much to everyone here! To anyone that plans to build something similar, feel free to ask any questions that may ariseI am more than willing to answer and hopefully, help you out.

Cheers!

I recently completed my build of a Brutus 10 "clone", minus the fancy electronicsit's all manually controlled. I wanted to post a photo of said brewing stand and say THANK YOU to EVERYONE that posts/posted on this site for the endless knowledge and needed insight that you all unknowingly provided to me throughout this build. It took me a little over a month to build the stand. Because of the knowledge provided here, I really think I made a quality, safe, kick-ass brewing stand.

I plan on taking more photos this week, and I'll post them when they're complete.

Again, thank you very much to everyone here! To anyone that plans to build something similar, feel free to ask any questions that may ariseI am more than willing to answer and hopefully, help you out.

Cheers!