pizzaman

Well-Known Member

[EDIT]

This thread is 30+ pages of my journey into kegging. I go through some very silly ideas and eventually wind up using cornelius kegs, a standard co2 regulator and a paintball sized co2 tank. I learned some interesting things along the way, and found and posted links to sites with all kinds of ingenuity related to kegging. If you are thinking about getting into kegging, do it. If you think you can come up with a better way than the methods already out there, please read this thread first.

My journey begins with the idea of using a bike pump and a water bottle......

[/EDIT]

I remember a few months back seeing a website selling kegs which required no CO2. They were basically a bottle with a plastic liner which you would put in some kind of pill which created expanding gasses. As more beer was siphoned out of the keg, the plastic bag would inflate more, taking the place of CO2.

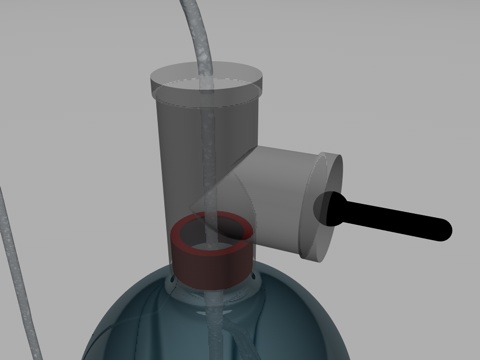

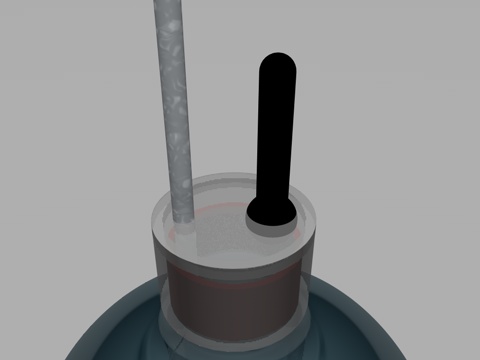

This got me thinking, what if I took a 5 gallon water bottle($5), put in a large, clean, plastic bag($1), connect a bike pump valve($2) to lead into this bag, attach the necessary kegging equipment($15?) to the vessels' lid, and voila! I have a reusable keg that I can pressurize with a few strokes of a bike pump(or the flip of a switch on a portable air pump).

Any relevant comments and thoughts are appreciated.

This thread is 30+ pages of my journey into kegging. I go through some very silly ideas and eventually wind up using cornelius kegs, a standard co2 regulator and a paintball sized co2 tank. I learned some interesting things along the way, and found and posted links to sites with all kinds of ingenuity related to kegging. If you are thinking about getting into kegging, do it. If you think you can come up with a better way than the methods already out there, please read this thread first.

My journey begins with the idea of using a bike pump and a water bottle......

[/EDIT]

I remember a few months back seeing a website selling kegs which required no CO2. They were basically a bottle with a plastic liner which you would put in some kind of pill which created expanding gasses. As more beer was siphoned out of the keg, the plastic bag would inflate more, taking the place of CO2.

This got me thinking, what if I took a 5 gallon water bottle($5), put in a large, clean, plastic bag($1), connect a bike pump valve($2) to lead into this bag, attach the necessary kegging equipment($15?) to the vessels' lid, and voila! I have a reusable keg that I can pressurize with a few strokes of a bike pump(or the flip of a switch on a portable air pump).

Any relevant comments and thoughts are appreciated.