IPAddict

Active Member

My cousin brews and has mentioned a few times that I should come down and brew with him. He bottles his beer and so I've mentioned that if he needs bottles I can help out. He prefers 22's, and well, after you drink them and rinse them, drying can be a pain. I don't putting it in the dishwasher and I don't like the idea of having some rinky dink dishwashing rack lying around just for drying bottles. I don't think they look appealing in any way, shape, or form, and I also don't like the bulky dimensions of them. Well, I don't have any wood working projects going on right now, and I thought this could itch my scratch. As the thread titles implies, I made a beer bottle drying rack.

I'm going into a lot of detail here, so I hope it helps those who aren't that confident with this type of stuff. If it's too long, or too detailed, or you don't like so many pictures, or whatever, then please don't read this thread. I'm hoping some people can find a use for this. This was scrap wood, and a project that didn't need to be super precise or even look anything near good, so don't be discouraged from it.

And off we go...

Dimensions:

3' wide

5.75" deep

5.5" tall

Dimensions give it a slim and low profile. I wanted it like that so you can use it or store it and just have it out of the way. It can hold 12 bottles, 22's or 12's. Made out of scrap wood I had lying around, as well as 8 screws.

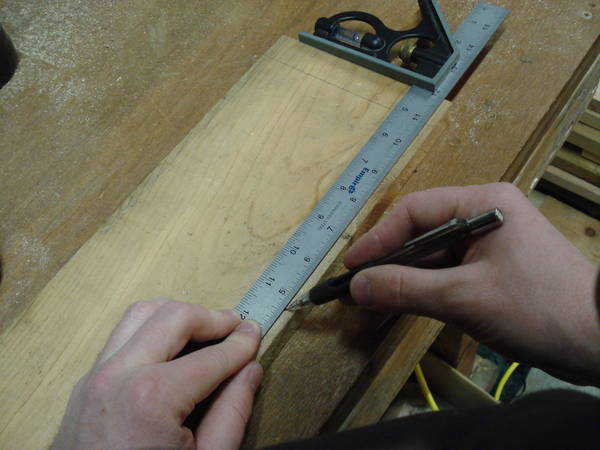

Started with a scrap plank of wood that was maybe 8' long, and is 5.75" deep and .75" thick. First I cut the plank 3' long.

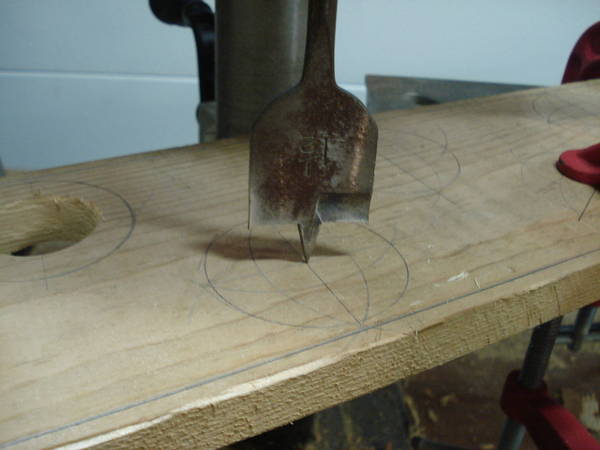

I placed the bottles on the plank to kind of give you an idea of how they will be arranged: 2 rows of 6, staggered.

I'm going into a lot of detail here, so I hope it helps those who aren't that confident with this type of stuff. If it's too long, or too detailed, or you don't like so many pictures, or whatever, then please don't read this thread. I'm hoping some people can find a use for this. This was scrap wood, and a project that didn't need to be super precise or even look anything near good, so don't be discouraged from it.

And off we go...

Dimensions:

3' wide

5.75" deep

5.5" tall

Dimensions give it a slim and low profile. I wanted it like that so you can use it or store it and just have it out of the way. It can hold 12 bottles, 22's or 12's. Made out of scrap wood I had lying around, as well as 8 screws.

Started with a scrap plank of wood that was maybe 8' long, and is 5.75" deep and .75" thick. First I cut the plank 3' long.

I placed the bottles on the plank to kind of give you an idea of how they will be arranged: 2 rows of 6, staggered.