PissyFingers

Well-Known Member

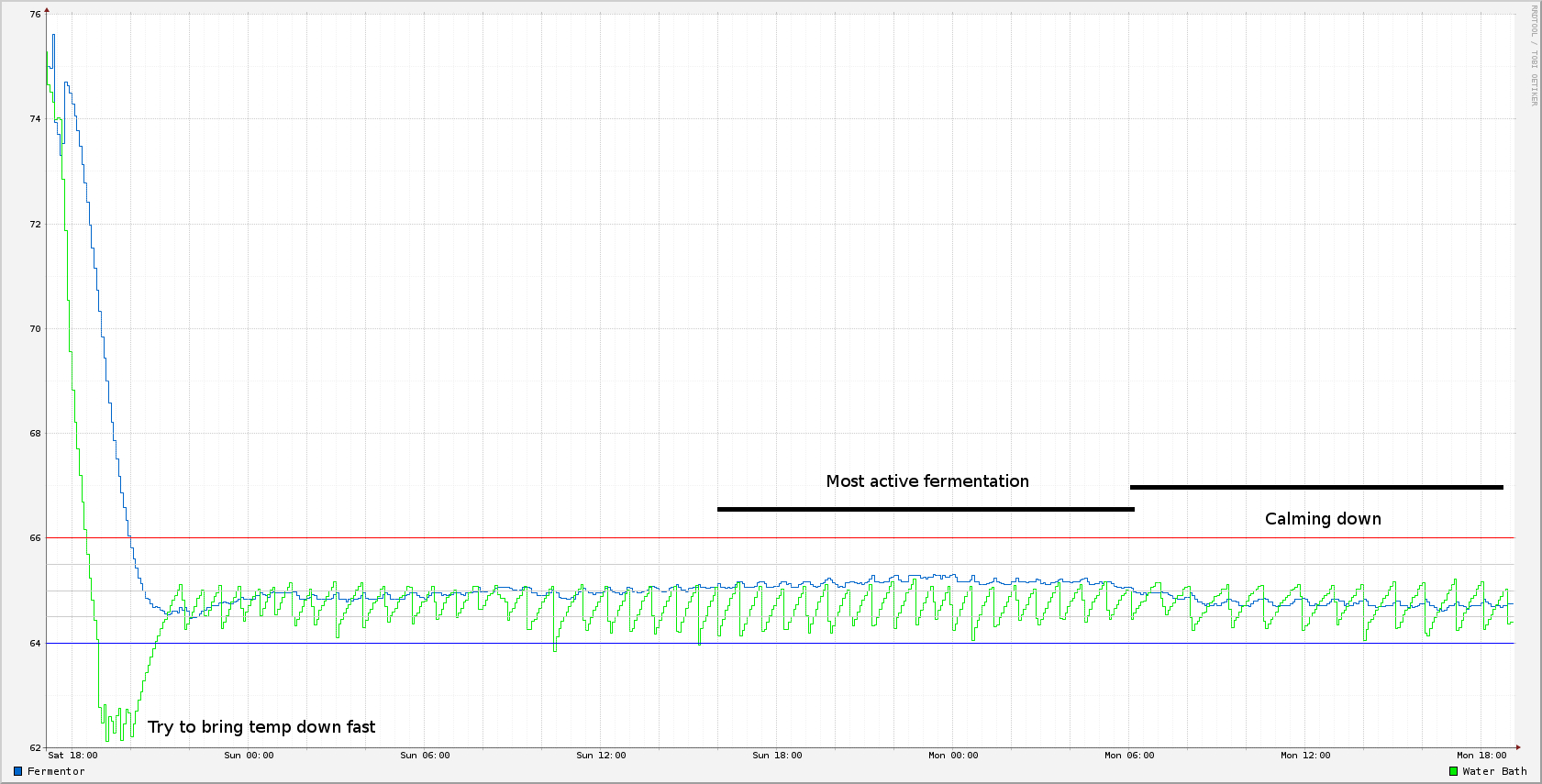

So i have a fridge i converted to a ferm chamber with temp controller. Question is what do i set my temp controller to, if i set it to 18C at the

start of fermentation when the yeast takes off (US 05) it creates so much energy the crystal temp strip on my primary reads 20-22C. But when the yeast calms down after 4 days or so it seems to settle back down to 18C.

Should i be setting the controller to 16C for the first few days to compensate the heat bought on by vigorous fermentation, then back to 18C when it slows down??

Did i make any sense?

start of fermentation when the yeast takes off (US 05) it creates so much energy the crystal temp strip on my primary reads 20-22C. But when the yeast calms down after 4 days or so it seems to settle back down to 18C.

Should i be setting the controller to 16C for the first few days to compensate the heat bought on by vigorous fermentation, then back to 18C when it slows down??

Did i make any sense?