Hello,

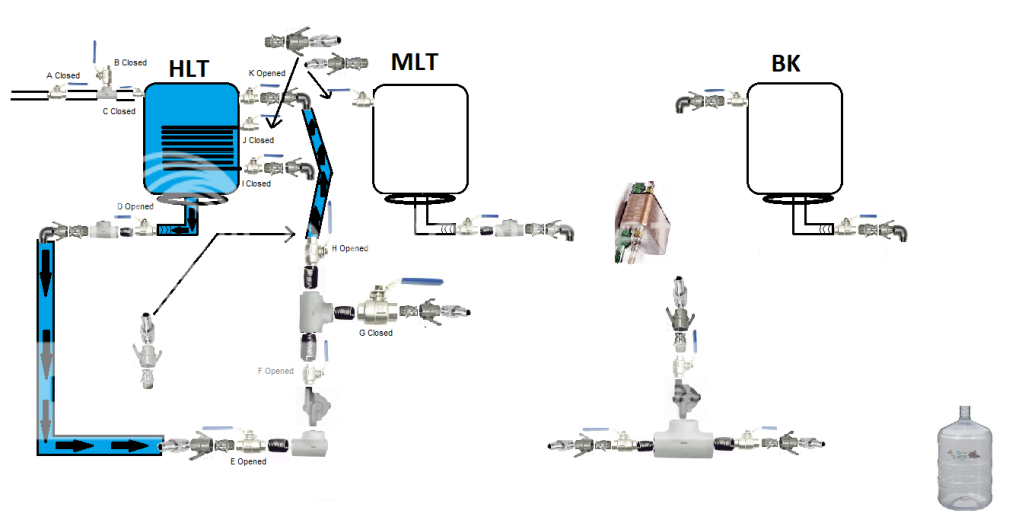

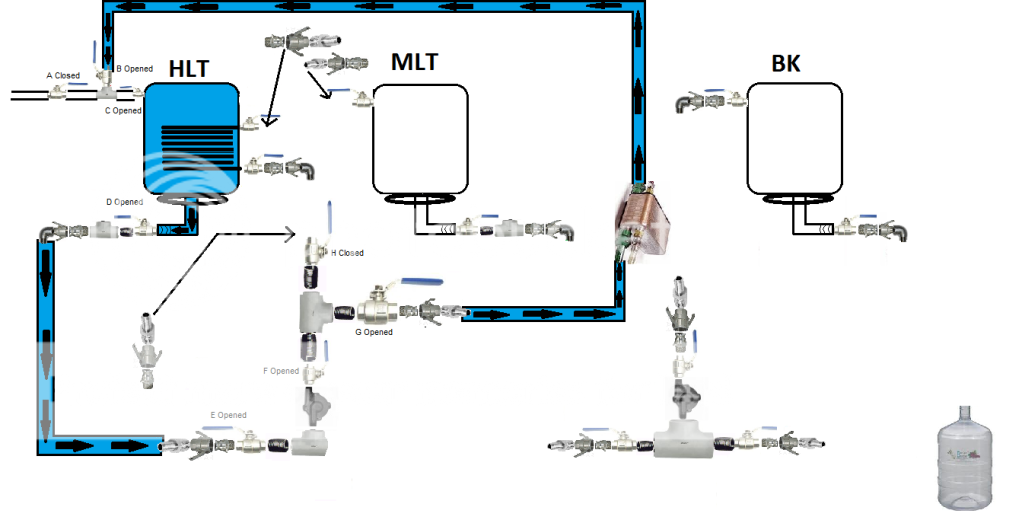

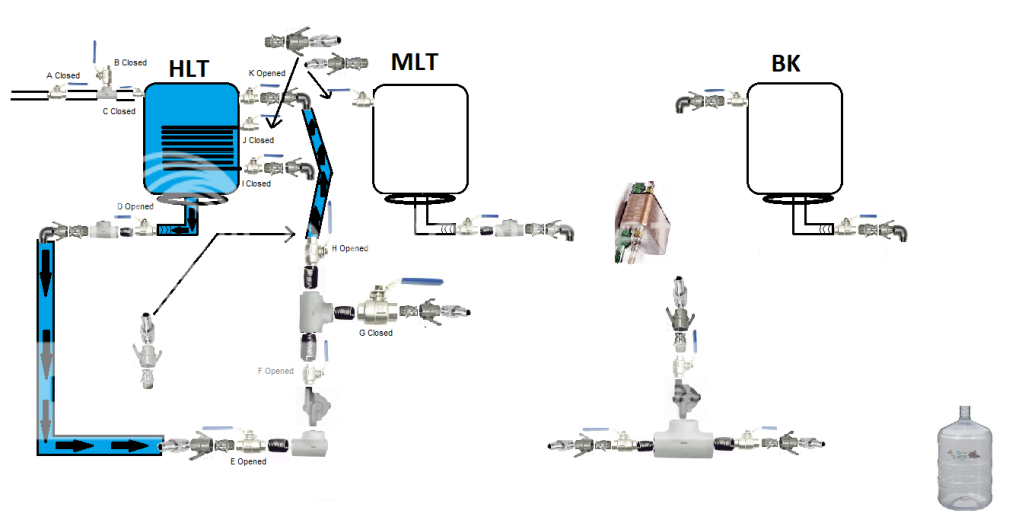

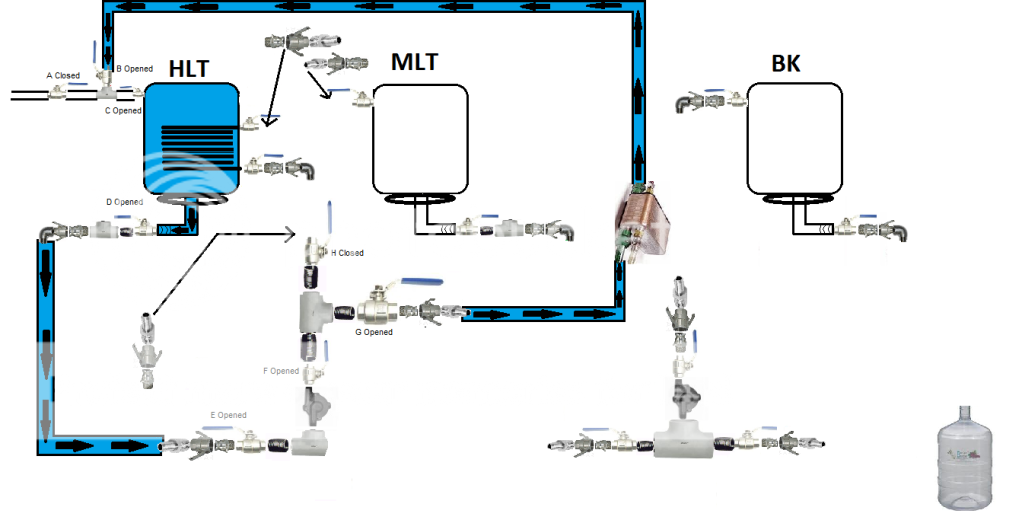

I need help with figuring out part of my plumbing for my rig. The part that I'm stuck on is how I'm going to do the recirculation of the water when it's in the HLT to warm up quicker. Below I have two pictures of what I came up with, but I'm not sure which one would be better.

I'm thinking the first setup is the best, but I do like the idea of the second picture, because I was already planning on recirculating ice cold water in the HLT when cooling the wort. The only concerns I had about the second picture is if there would be an issue of contamination with my brewing water, since it's going through the plate chiller.

One friend mentioned he would be concerned about mineral deposit build up in the plate chiller which could cause issues with my brew water. If this is true, I would think then I would have issues with my entire plumbing. Since I had plan on recirculating the ice cold water in the HLT during the cooling of the wort, which would be pushing contaminated water through all the silicone tubing, but I would think when I do my cleaning process, this would take care of it.

As you can see I have a lot on my mind and if you could give any advice, I would greatly appreciate it. Thanks.

I need help with figuring out part of my plumbing for my rig. The part that I'm stuck on is how I'm going to do the recirculation of the water when it's in the HLT to warm up quicker. Below I have two pictures of what I came up with, but I'm not sure which one would be better.

I'm thinking the first setup is the best, but I do like the idea of the second picture, because I was already planning on recirculating ice cold water in the HLT when cooling the wort. The only concerns I had about the second picture is if there would be an issue of contamination with my brewing water, since it's going through the plate chiller.

One friend mentioned he would be concerned about mineral deposit build up in the plate chiller which could cause issues with my brew water. If this is true, I would think then I would have issues with my entire plumbing. Since I had plan on recirculating the ice cold water in the HLT during the cooling of the wort, which would be pushing contaminated water through all the silicone tubing, but I would think when I do my cleaning process, this would take care of it.

As you can see I have a lot on my mind and if you could give any advice, I would greatly appreciate it. Thanks.