brewtime

Well-Known Member

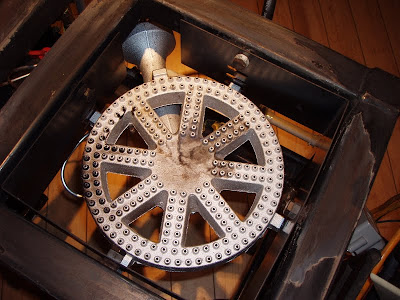

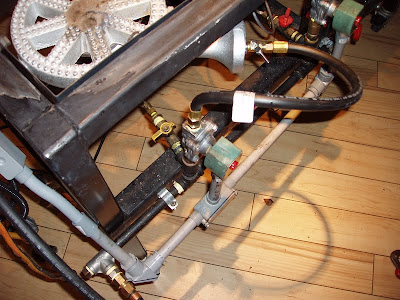

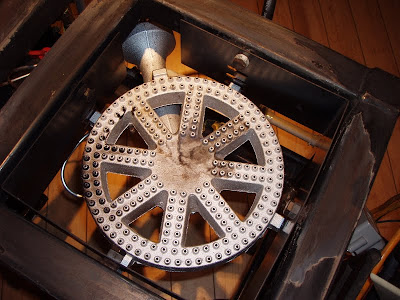

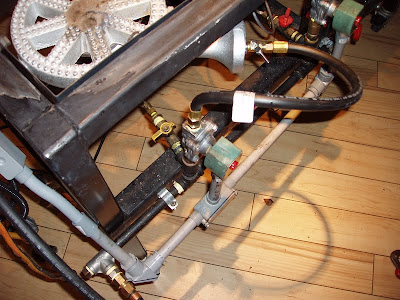

So i have a Brutus style stand and I recently switched out the burner under my HLT. The old burner was a 10 tipped jet burner and I replaced it with the banjo burner Brewershardware.com. I also installed a heat/windshield from Brewsteel.com. The problem I am having is I can dial in the flame where it is blue with no yellow. Once I put the kettle over the burner it the flame goes yellow and and shoots up the side of the kettle.

could it be that the burner is getting O2 starved once the kettle is placed over the burner.

could it be that the burner is getting O2 starved once the kettle is placed over the burner.