chainsawbrewing

Well-Known Member

i've been reading a crap ton on electric brewing over the last week. lot's of information!

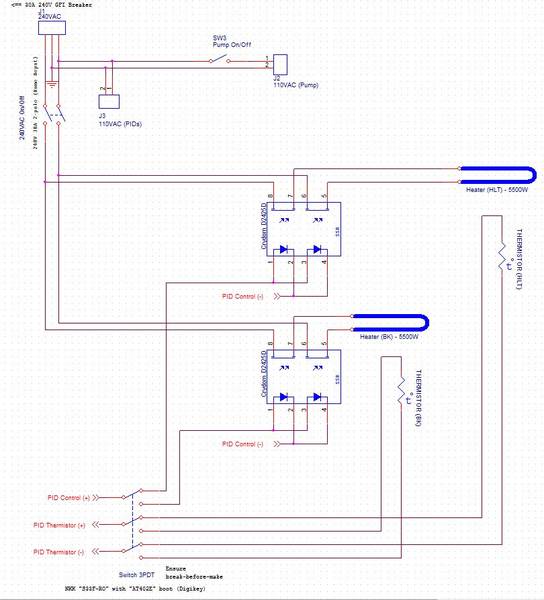

i've seen people build a box, control center if you will, that holds the pid, and the ssr, usually a couple switches to be able to completely cut the power to the elements if needed. also looks like a 120v lead goes from an outlet somewhere else, into this control center/box with two or four gfci plugs, to power up the pid and ssr, and/or a mixing paddle, etc.

also most of the set ups i've seen have a female 220v plug in in the wall somewhere, then from that they have a dryer plug plugged into it, and then the end of that plug also runs into this control center/build box, and they will have another female 220v dryer plug in the side of the box, for plugging in your element. i'm "assuming" that this is just done as a sort of extension, so that you don't have to have a really long wire from your elements to reach over to the wall, and also i would assume it's done so you can have a switch wired to kill the power to the element if needed?

what i can't figure out is, i haven't seen one of these controller boxes with two female 240v outlets on them, however i've seen them set up with a dual element set up, one for the BK and one for the HLT.

are people just plugging in the HLT element, and then when they're ready to boil, turn off the HLT element, unplug it, then plug in the BK element to the same female 240v plug in, turn it on, and boil?

does anyone have a set up with two seperate plug ins, where you can have your HLT element, and BK element both on at the same time, or at least not have to unplug one to plug in the other?

i would assume if someone does have a set up like this, you would have to have two seperate 240v 30a power sources, one for each element, right?

i've seen people build a box, control center if you will, that holds the pid, and the ssr, usually a couple switches to be able to completely cut the power to the elements if needed. also looks like a 120v lead goes from an outlet somewhere else, into this control center/box with two or four gfci plugs, to power up the pid and ssr, and/or a mixing paddle, etc.

also most of the set ups i've seen have a female 220v plug in in the wall somewhere, then from that they have a dryer plug plugged into it, and then the end of that plug also runs into this control center/build box, and they will have another female 220v dryer plug in the side of the box, for plugging in your element. i'm "assuming" that this is just done as a sort of extension, so that you don't have to have a really long wire from your elements to reach over to the wall, and also i would assume it's done so you can have a switch wired to kill the power to the element if needed?

what i can't figure out is, i haven't seen one of these controller boxes with two female 240v outlets on them, however i've seen them set up with a dual element set up, one for the BK and one for the HLT.

are people just plugging in the HLT element, and then when they're ready to boil, turn off the HLT element, unplug it, then plug in the BK element to the same female 240v plug in, turn it on, and boil?

does anyone have a set up with two seperate plug ins, where you can have your HLT element, and BK element both on at the same time, or at least not have to unplug one to plug in the other?

i would assume if someone does have a set up like this, you would have to have two seperate 240v 30a power sources, one for each element, right?