rerobb

Well-Known Member

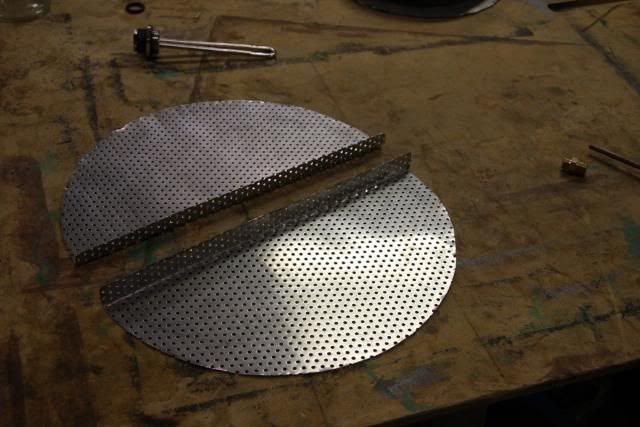

So, I can get 2 - 18 inch squares of titanium perf with 3/32 holes for free! My question is there any reason I can't use them to make false bottoms for my keggle projects instead of buying stainless?

Also, can you weld stainless hinges to titanium?

Also, can you weld stainless hinges to titanium?