- Joined

- Nov 6, 2008

- Messages

- 660

- Reaction score

- 9

I just got a two keg kegerator from Keg Connection.

When trying to set it up, no matter what I do, I can't seem to get any CO2 to flow to the kegs.

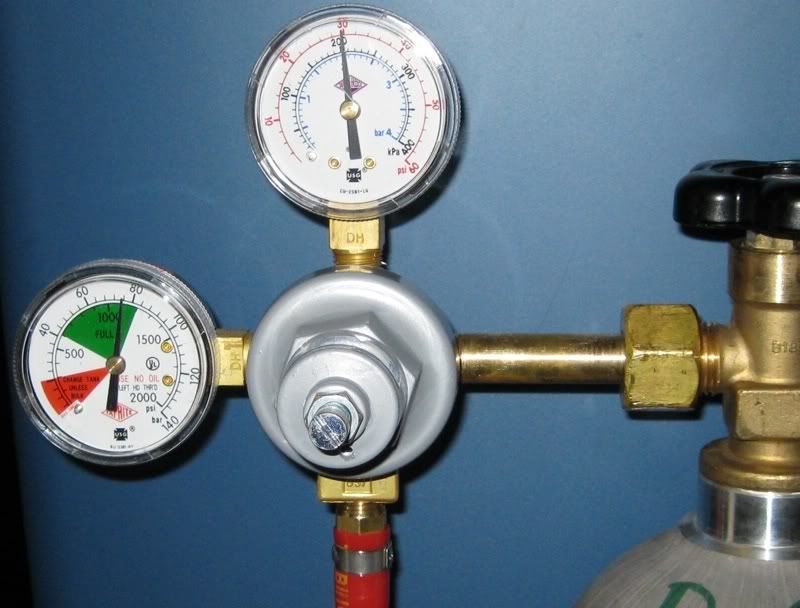

The CO2 tank is full, the regulator shows a full tank and is set to 30 PSI.

The gas disconnect is attached to the keg, but nothing flows.

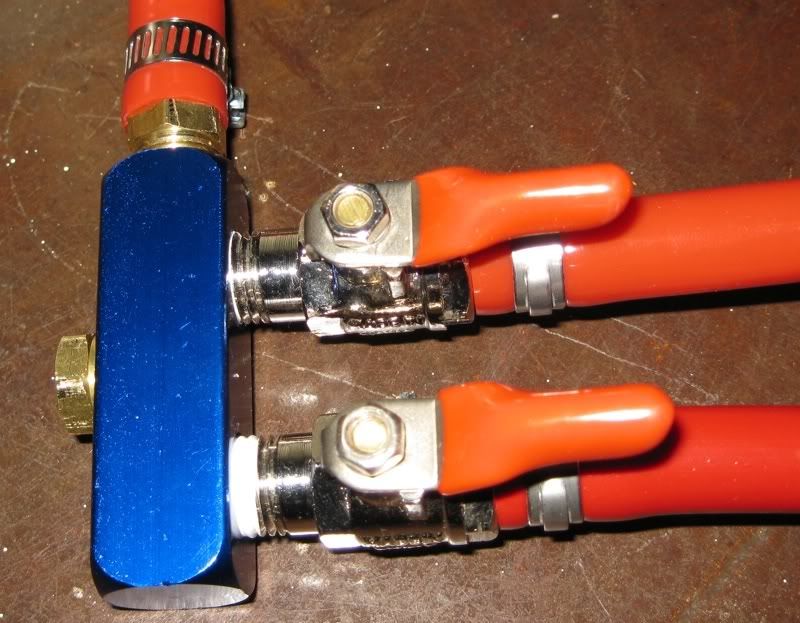

I have tried the stopcocks in all positions, but cannot get the keg to pressurize.

Any help is appreciated. I am getting very frustrated.

When trying to set it up, no matter what I do, I can't seem to get any CO2 to flow to the kegs.

The CO2 tank is full, the regulator shows a full tank and is set to 30 PSI.

The gas disconnect is attached to the keg, but nothing flows.

I have tried the stopcocks in all positions, but cannot get the keg to pressurize.

Any help is appreciated. I am getting very frustrated.