Finally getting some progress updated. This 1st batch of pics are a little out of order from the rest to follow....

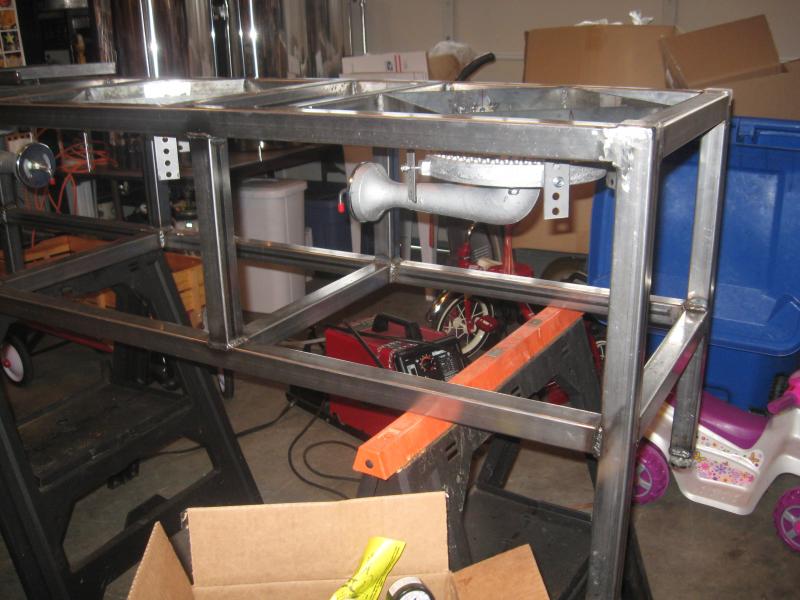

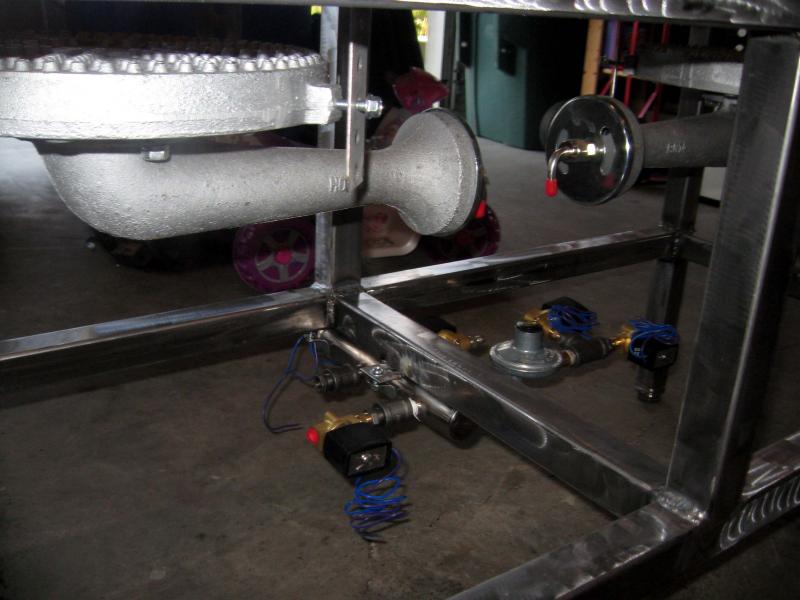

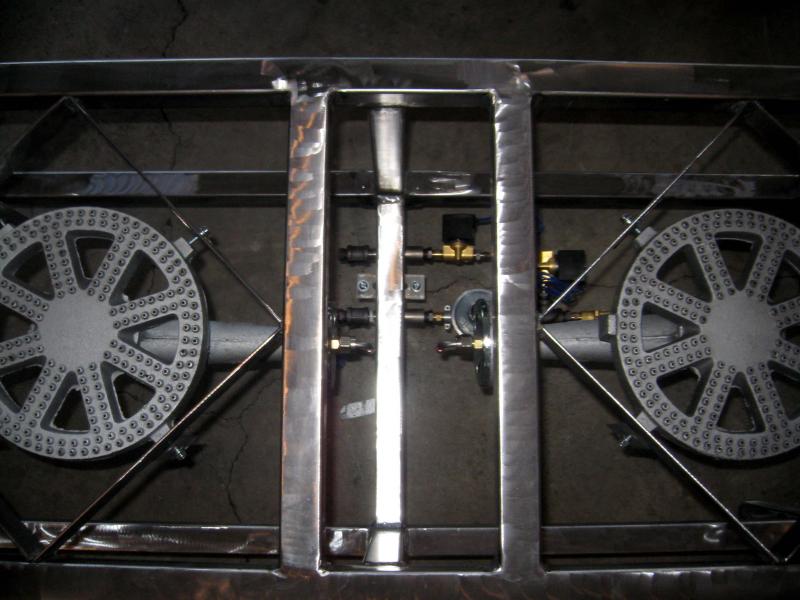

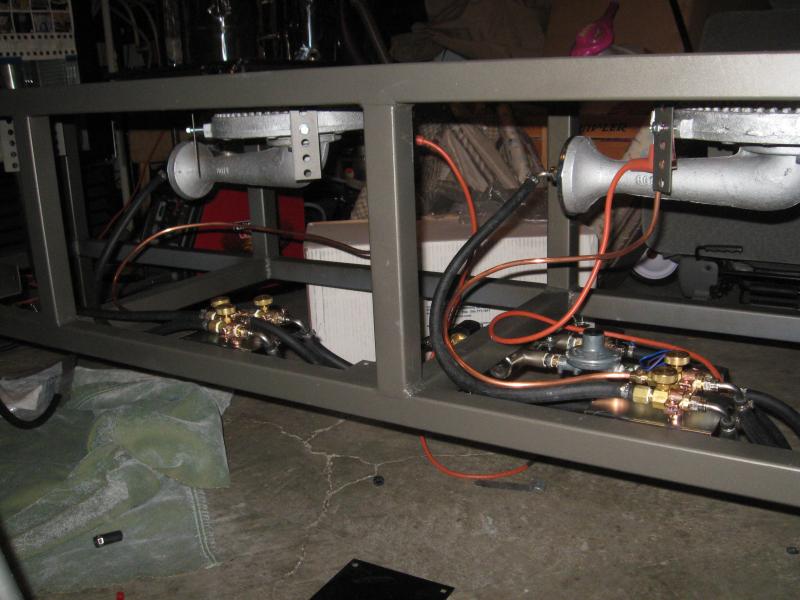

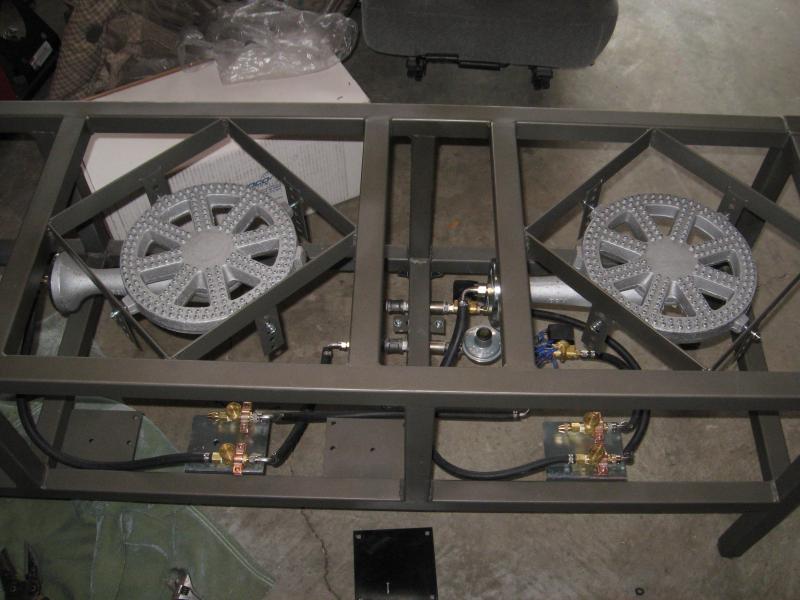

The burners are mounted....we only have 2 right now...the 3rd will be removed from our current system at the last minute....along with the 2nd pump.

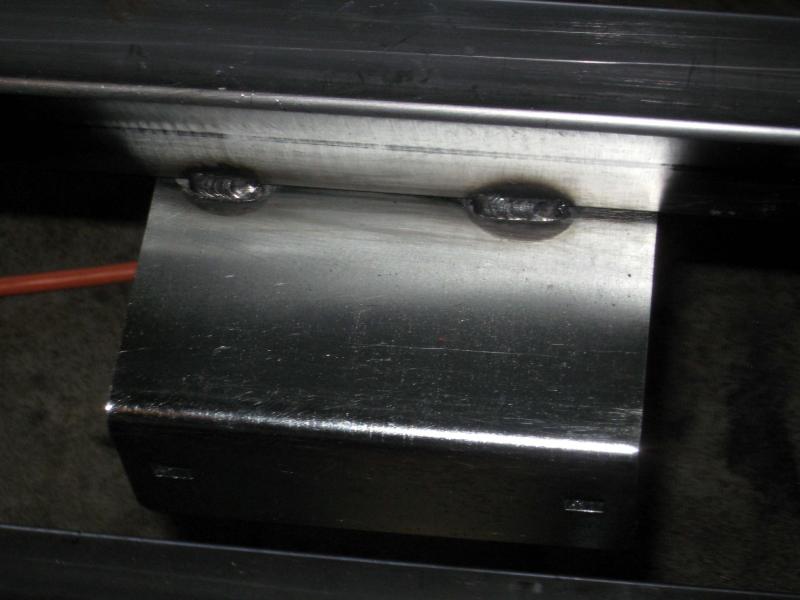

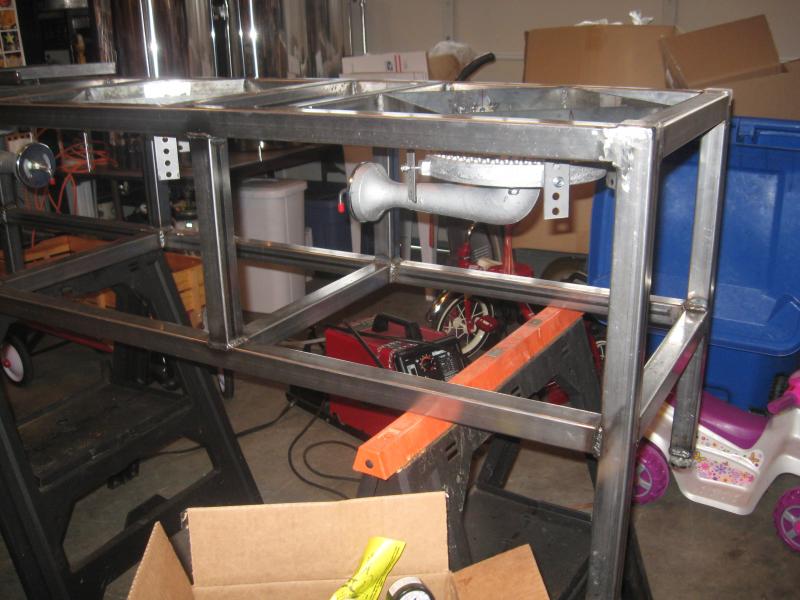

I polished up the stand with 120 grit on the angle grinder...so now I am mocking up the the gas system.....then I will disassemble and paint the stand.

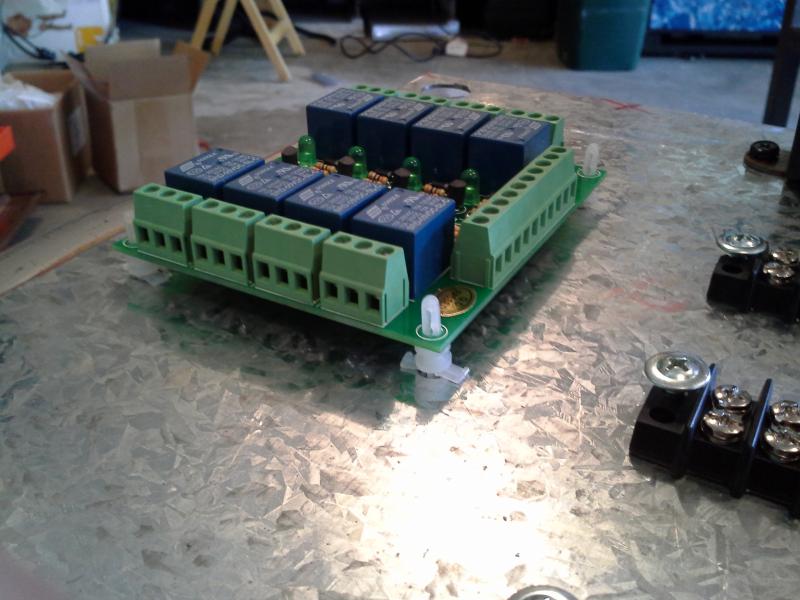

After that....it will be time to reassemble and get on to the electrical system.

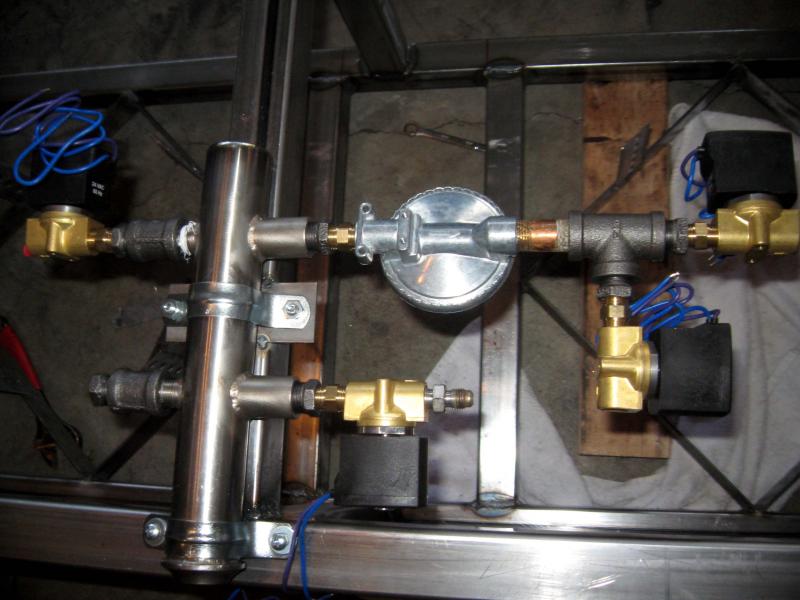

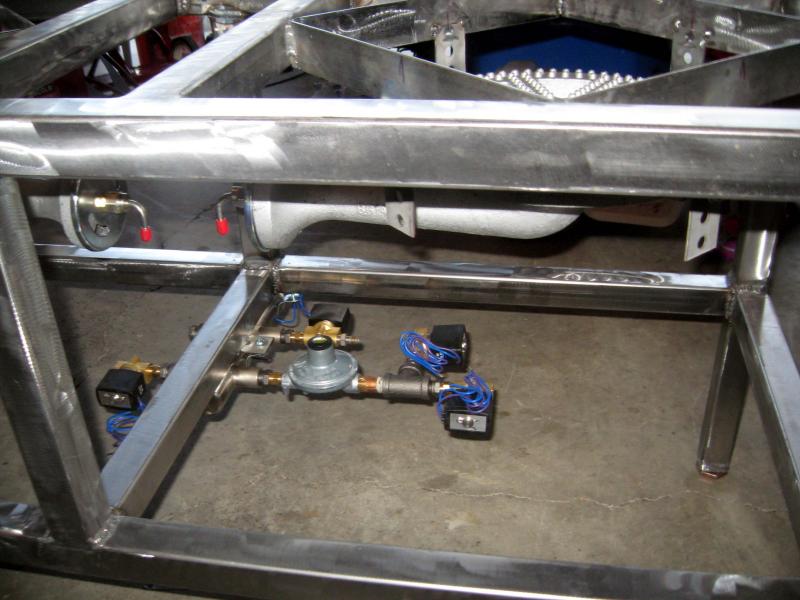

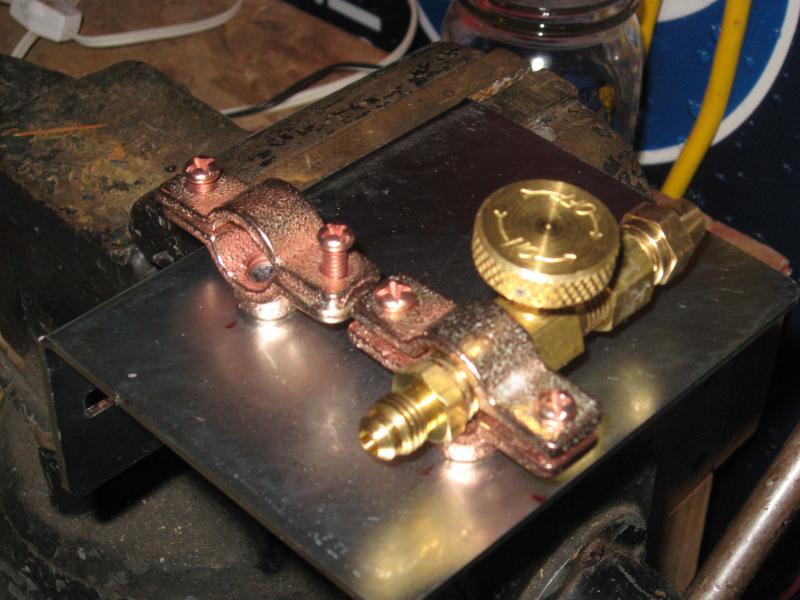

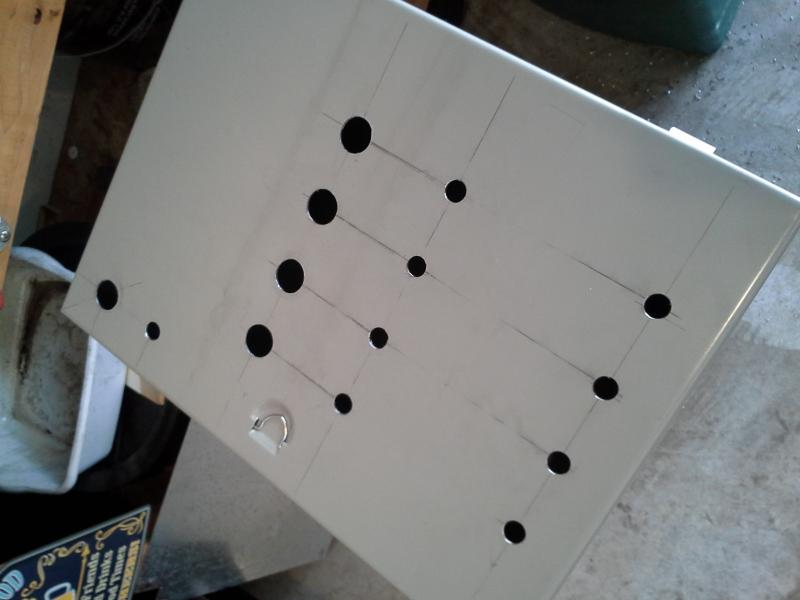

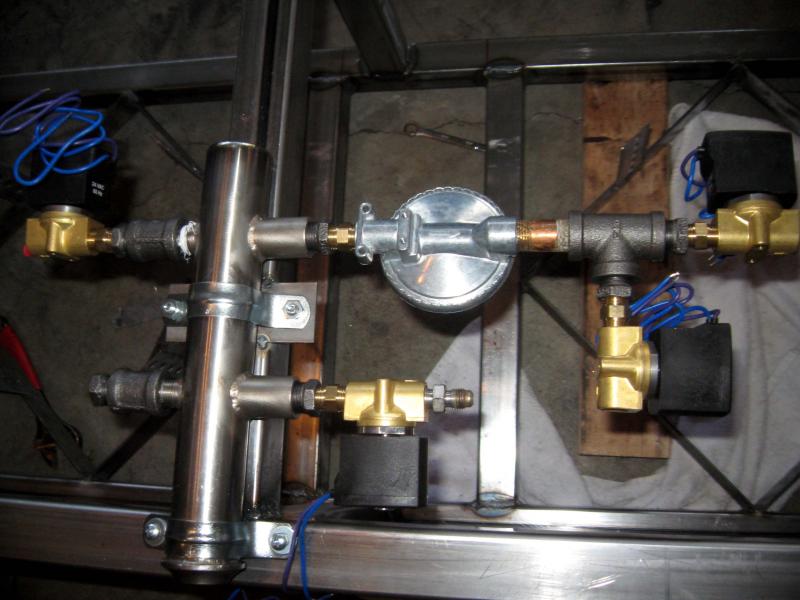

The last 2 pics are of the gas manifold....the stand is flipped upside down.

The burners are mounted....we only have 2 right now...the 3rd will be removed from our current system at the last minute....along with the 2nd pump.

I polished up the stand with 120 grit on the angle grinder...so now I am mocking up the the gas system.....then I will disassemble and paint the stand.

After that....it will be time to reassemble and get on to the electrical system.

The last 2 pics are of the gas manifold....the stand is flipped upside down.