Recently I moved to A.G. though I also do some extract and BIAB. Over the weekend I figured out what I needed to make the process a little easier and safer.

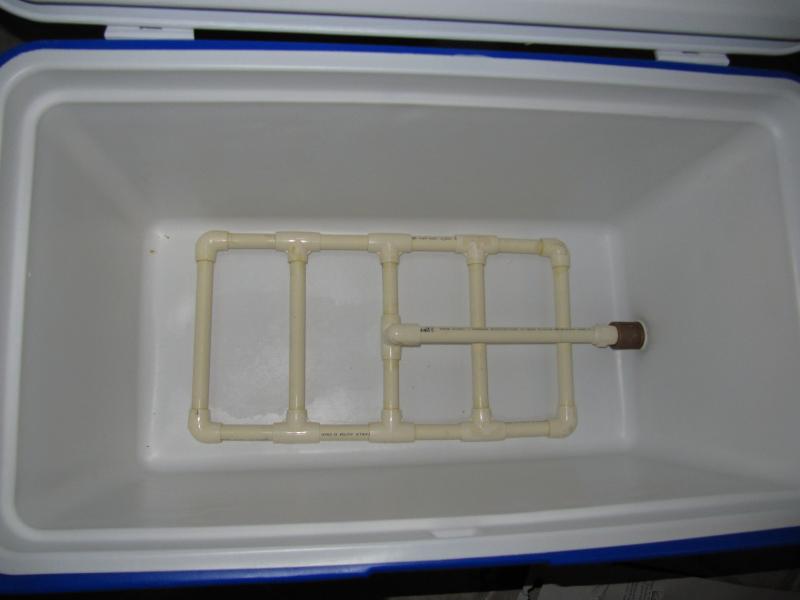

I ordered some SS weldless valve/bulkhead fittings for both my BK and my HLT as well as a thermometer and weldless fitting to mount it into the HLT. There will also be quick disconnects to add to the BK valve, the HLT valve, and the MLT valve. Another bulkhead is going to be mounted on the top of the cooler with a QD so I can sparge through a sprinkler of some sort. The final part of the order was two hoses with QD that I can swap around depending on which stage I'm working on.

In the meantime, I have added a bulkhead through the top of my cooler MLT for a turkey fryer thermometer in order to monitor the mash temp without opening the lid.

My question: My eventual goal is to have a more steady-state process where I can hold temps steady or move them as required. To achieve this, is my next step a March Pump?

My comment: If anyone is contemplating similar, let me know and I can add photos with descriptions. As anyone who knows me can attest, I am not particularly hands-on, but to this point it has been a lot of fun and all has gone well with the MLT.

B

I ordered some SS weldless valve/bulkhead fittings for both my BK and my HLT as well as a thermometer and weldless fitting to mount it into the HLT. There will also be quick disconnects to add to the BK valve, the HLT valve, and the MLT valve. Another bulkhead is going to be mounted on the top of the cooler with a QD so I can sparge through a sprinkler of some sort. The final part of the order was two hoses with QD that I can swap around depending on which stage I'm working on.

In the meantime, I have added a bulkhead through the top of my cooler MLT for a turkey fryer thermometer in order to monitor the mash temp without opening the lid.

My question: My eventual goal is to have a more steady-state process where I can hold temps steady or move them as required. To achieve this, is my next step a March Pump?

My comment: If anyone is contemplating similar, let me know and I can add photos with descriptions. As anyone who knows me can attest, I am not particularly hands-on, but to this point it has been a lot of fun and all has gone well with the MLT.

B

![IMG_5763[1].jpg IMG_5763[1].jpg](https://cdn.homebrewtalk.com/data/attach/32/32561-IMG-5763-1-.jpg)

![IMG_5764[1].jpg IMG_5764[1].jpg](https://cdn.homebrewtalk.com/data/attach/32/32562-IMG-5764-1-.jpg)

![IMG_5765[1].jpg IMG_5765[1].jpg](https://cdn.homebrewtalk.com/data/attach/32/32563-IMG-5765-1-.jpg)

![IMG_5766[1].jpg IMG_5766[1].jpg](https://cdn.homebrewtalk.com/data/attach/32/32624-IMG-5766-1-.jpg)

![IMG_5767[1].jpg IMG_5767[1].jpg](https://cdn.homebrewtalk.com/data/attach/32/32625-IMG-5767-1-.jpg)

![IMG_5768[1].jpg IMG_5768[1].jpg](https://cdn.homebrewtalk.com/data/attach/32/32626-IMG-5768-1-.jpg)

![IMG_5770[1].jpg IMG_5770[1].jpg](https://cdn.homebrewtalk.com/data/attach/32/32629-IMG-5770-1-.jpg)

![IMG_5771[1].jpg IMG_5771[1].jpg](https://cdn.homebrewtalk.com/data/attach/32/32630-IMG-5771-1-.jpg)

![IMG_5773[1].jpg IMG_5773[1].jpg](https://cdn.homebrewtalk.com/data/attach/32/32631-IMG-5773-1-.jpg)

![IMG_5774[1].jpg IMG_5774[1].jpg](https://cdn.homebrewtalk.com/data/attach/32/32632-IMG-5774-1-.jpg)