paledragon

Well-Known Member

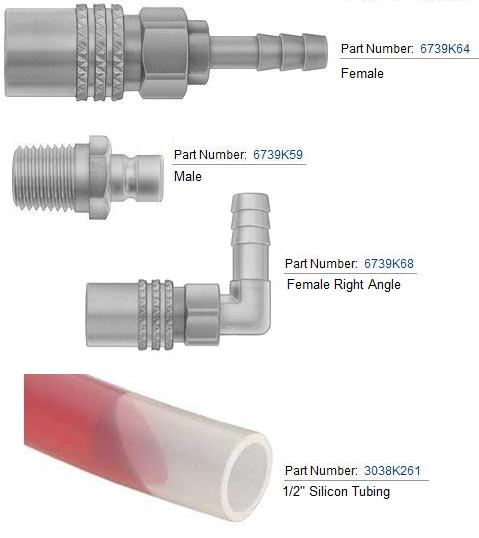

while contemplating version 2 of my herms system, i came across mcmaster's through-wall/bulkhead pages for the first time. i'm not sure i've ever seen these parts referenced on HBT before (apologies if they have). anyway, for anyone looking for plastic, stainless, threaded, unthreaded, weldless, or welded fittings, this looks to be the jackpot.

p.d.

p.d.