bellinmi88

Well-Known Member

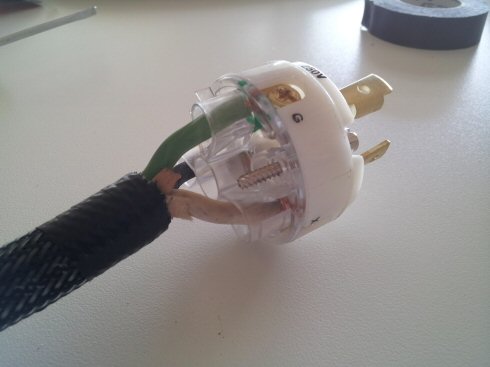

Started to convert my Keggle to electric following Kal's methods:

The Materials:

I started with cutting the hole in the keg using the Greenlee Radio Punch (which I would be willing to rent out to anyone on this forum for a weekend):

Once the hole was cut in the Keg I used the same Radio Punch which was 1.25" to cut the hole in the box cover. I used a step bit from Harbor Freight to drill the initial hole for the Radio Punch.

Here is the 5500 Watt ULD Element dry fitted into the new hole.

The Materials:

I started with cutting the hole in the keg using the Greenlee Radio Punch (which I would be willing to rent out to anyone on this forum for a weekend):

Once the hole was cut in the Keg I used the same Radio Punch which was 1.25" to cut the hole in the box cover. I used a step bit from Harbor Freight to drill the initial hole for the Radio Punch.

Here is the 5500 Watt ULD Element dry fitted into the new hole.