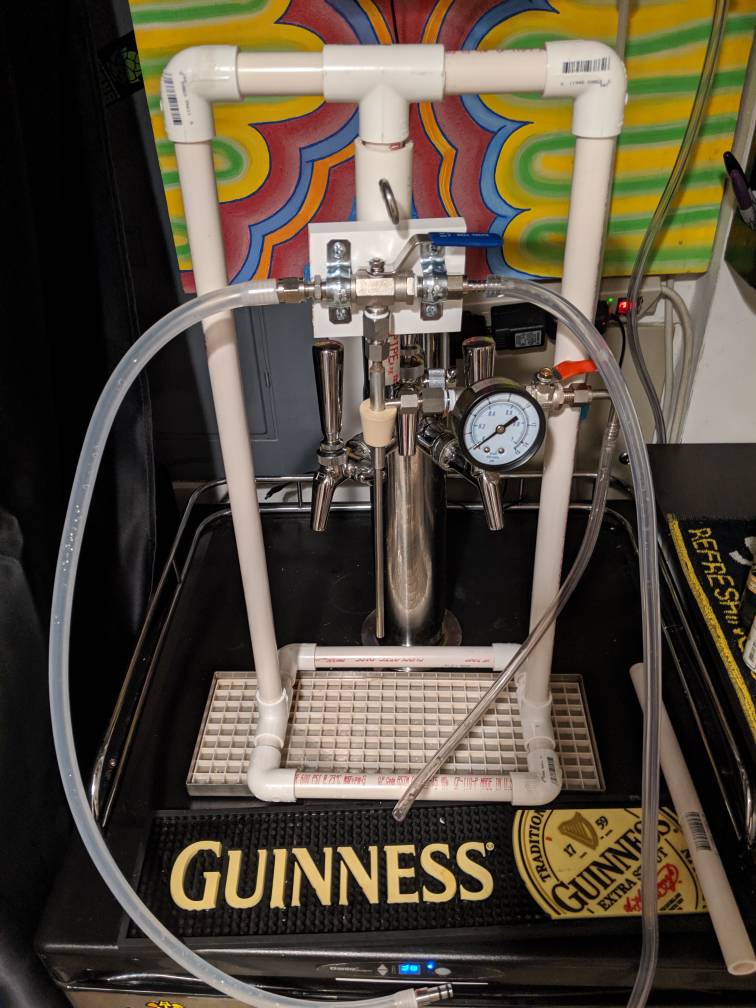

I was getting tired of holding my CP Bottle Filler while filling bottles slowly so not to get much foam. I hate just standing there and not being able to do anything like capping bottles or getting others ready to fill. So I designed this stand that holds the stopper of the filler with spring pressure in the bottle while I get other bottles ready or cap already filled bottles. I have used it and it works great. Now I can multitask with ease.