I have a problem. When I look at my brewery I think that if it is working, then it doesn't have enough features. Certain parts of the brewing process suggest specific liquid flow rates, but without instantaneous feedback, how can anyone ever really judge if they're doing it right? It seemed that commercial flow meters are complete garbage or are insanely expensive. Luckily, Adafruit had my back with an inexpensive flow sensor.

I slapped a couple quick disconnects on it, and replaced the screws that held it together with 3/4" #4 brass wood screws to allow it to be mounted to a nice enclosure.

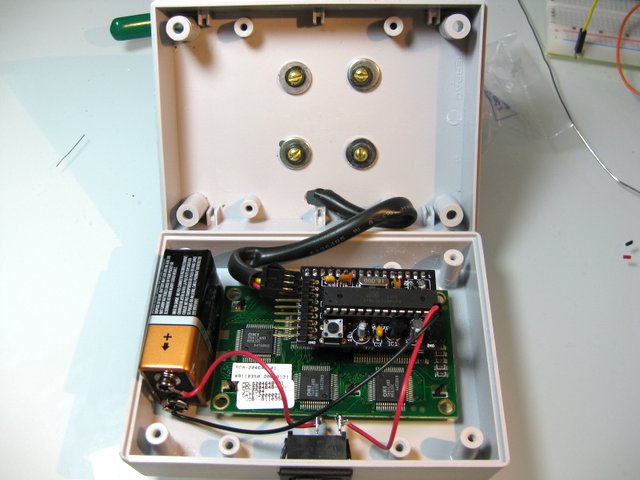

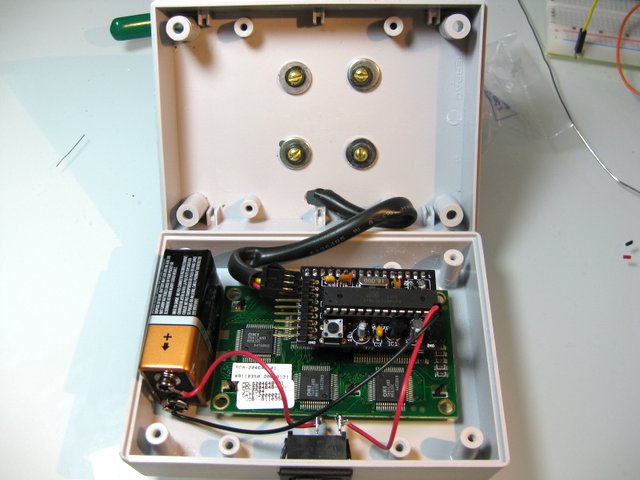

The rest of the parts were maybe $15-20, but I had them sitting around from my other projects. I need to get a 9V battery clip. Soldering wires onto a 9V battery because you're more excited about getting it working than driving to Radio Shack is surprisingly difficult.

The PCB is custom made from OSH Park and drives the LCD, PWM backlight and contrast, and of course counts the sensor pulses. I went a slightly different way than the example sketch does it, because I found that the resolution at low flow rates was too coarse. I use Timer1 set to 62.5Khz and use the input capture interrupt to store the elapsed ticks between pulses.

The sensor works great, but is quite a bit off spec (450 pulses per liter) at flow rates less than 4 lpm. I calibrated by running hundreds of liters of water through it and creating some calibration points that I can LERP between. Flow rate accuracy now pretty tight, off by a couple percent. Careful calibration can take this sensor down below its minimum spec'ed flow rate, down to about 0.7 lpm, but the pulses-per-liter count at that rate changes dramatically.

Here's some pictures of the device in action on the brewery, where it just snaps on to the existing pump infrastructure. Using sleep modes between pulses means the current draw is relatively low and the 9V battery should last roughly 30 hours in use.

I still need to come up with some way of covering the front panel to keep errant beer out.

I slapped a couple quick disconnects on it, and replaced the screws that held it together with 3/4" #4 brass wood screws to allow it to be mounted to a nice enclosure.

The rest of the parts were maybe $15-20, but I had them sitting around from my other projects. I need to get a 9V battery clip. Soldering wires onto a 9V battery because you're more excited about getting it working than driving to Radio Shack is surprisingly difficult.

The PCB is custom made from OSH Park and drives the LCD, PWM backlight and contrast, and of course counts the sensor pulses. I went a slightly different way than the example sketch does it, because I found that the resolution at low flow rates was too coarse. I use Timer1 set to 62.5Khz and use the input capture interrupt to store the elapsed ticks between pulses.

The sensor works great, but is quite a bit off spec (450 pulses per liter) at flow rates less than 4 lpm. I calibrated by running hundreds of liters of water through it and creating some calibration points that I can LERP between. Flow rate accuracy now pretty tight, off by a couple percent. Careful calibration can take this sensor down below its minimum spec'ed flow rate, down to about 0.7 lpm, but the pulses-per-liter count at that rate changes dramatically.

Here's some pictures of the device in action on the brewery, where it just snaps on to the existing pump infrastructure. Using sleep modes between pulses means the current draw is relatively low and the 9V battery should last roughly 30 hours in use.

I still need to come up with some way of covering the front panel to keep errant beer out.

Last edited by a moderator: