I've been planning my electric brewery for ~ 10 months, and I want to document the entire build project. I am planning on relying 90% on the plans from theelectricbrewery.com.

First about myself, I'm 23 years old and recently graduated college. I've brewed a couple times with friends, and I really enjoyed the process. I also really enjoy good beer so I decided the only rational decision would be to get into brewing. With a new job, and the necessary money, I thought I would skip extract brewing and partial mash, and skip straight to an all-grain operation. I've got 30 days before I start my job, so I'm hoping to get the majority of it done in the next month. I'm still waiting on a good amount of the parts to arrive, but as soon as they get here, this thread should take off.

The build will be very similar to the electricbrewery.com plans except for the following:

-I'm using kegs for the MLT, HLT, and Boil Kettle

-I intend to use silver solder for all of my fittings. I talked to a local welder, and he wanted to MIG everything for me. I decided to read the soldering stainless thread, and think I will enjoy the entire soldering process myself.

-I intend to use the BCS-462 controller opposed to the control panel from theelectricbrewery.com

Cameron

First about myself, I'm 23 years old and recently graduated college. I've brewed a couple times with friends, and I really enjoyed the process. I also really enjoy good beer so I decided the only rational decision would be to get into brewing. With a new job, and the necessary money, I thought I would skip extract brewing and partial mash, and skip straight to an all-grain operation. I've got 30 days before I start my job, so I'm hoping to get the majority of it done in the next month. I'm still waiting on a good amount of the parts to arrive, but as soon as they get here, this thread should take off.

The build will be very similar to the electricbrewery.com plans except for the following:

-I'm using kegs for the MLT, HLT, and Boil Kettle

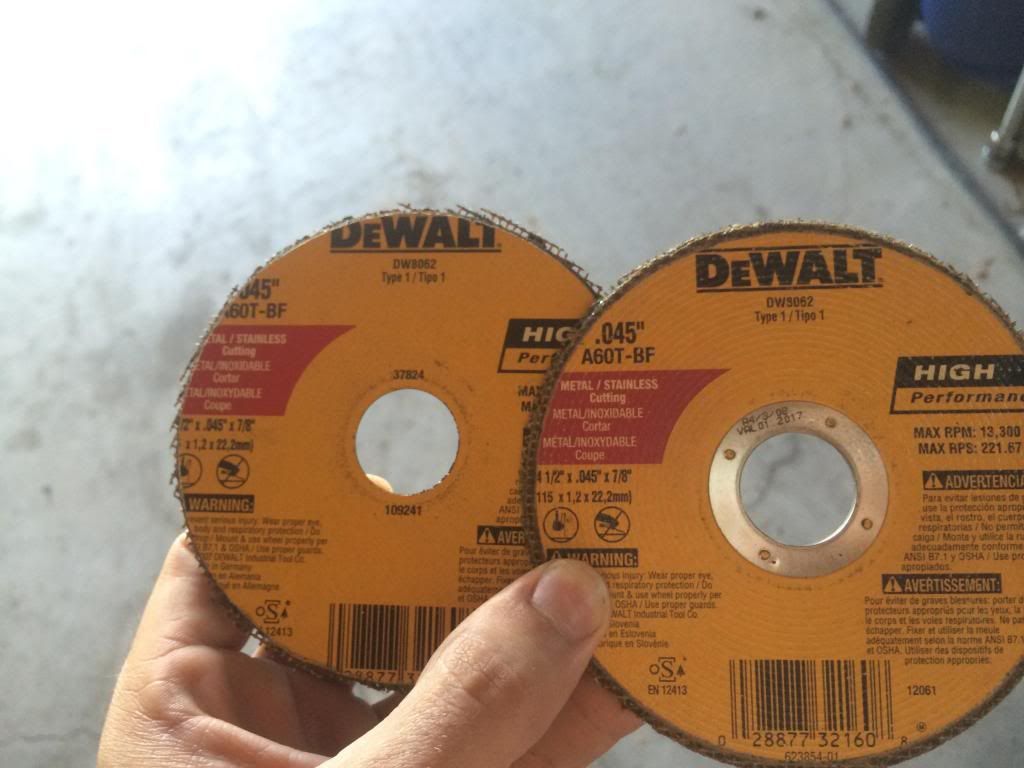

-I intend to use silver solder for all of my fittings. I talked to a local welder, and he wanted to MIG everything for me. I decided to read the soldering stainless thread, and think I will enjoy the entire soldering process myself.

-I intend to use the BCS-462 controller opposed to the control panel from theelectricbrewery.com

Cameron