kennywd

Well-Known Member

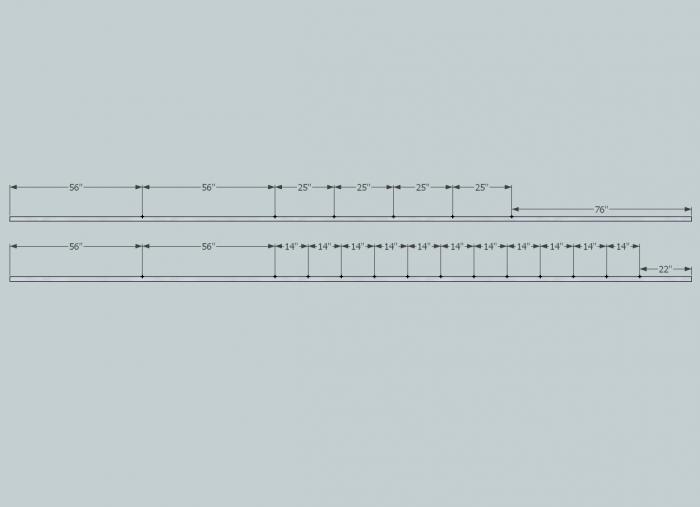

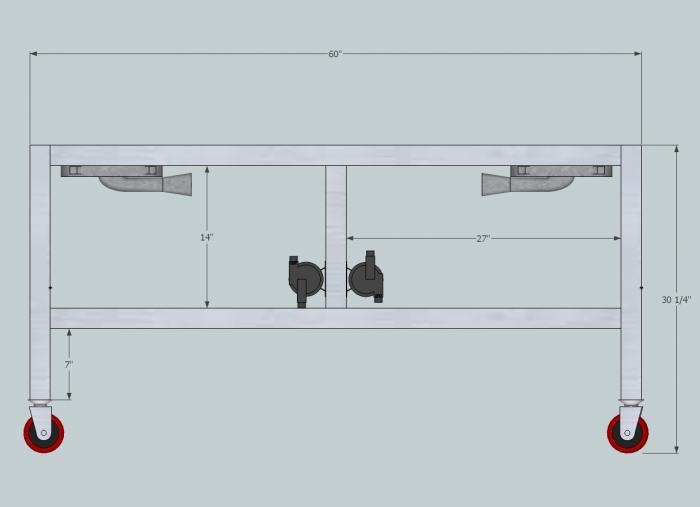

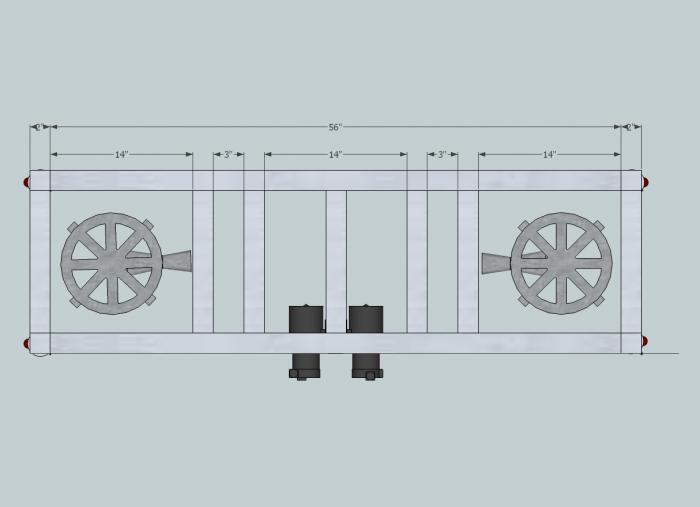

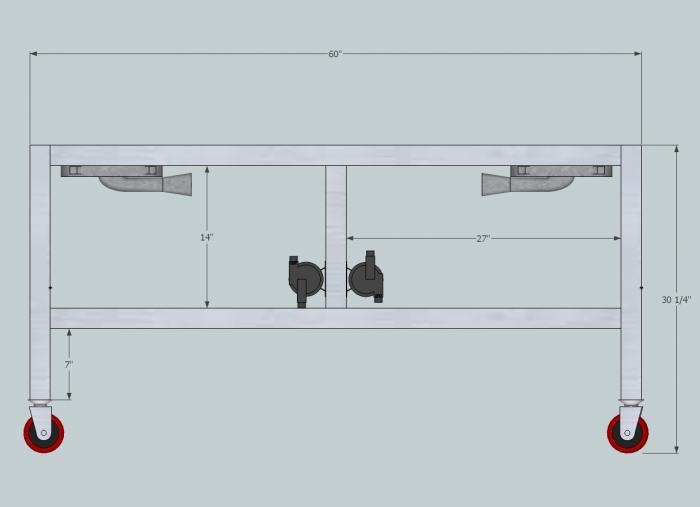

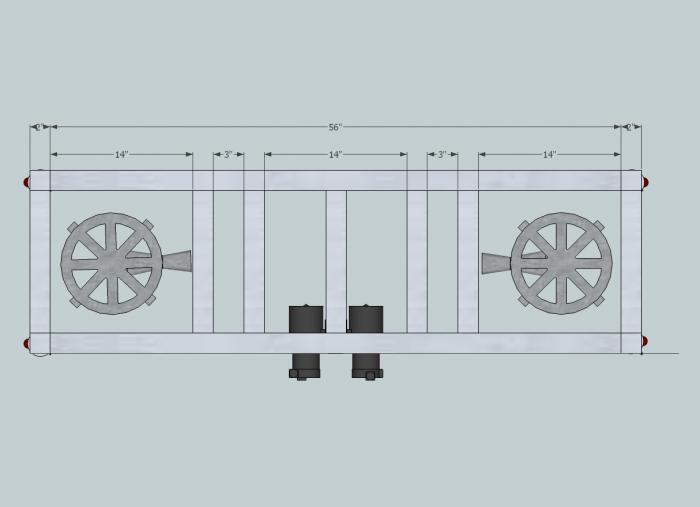

So I am starting my build of a Brutus 10 build with plans. I am still hashing out the details so this is a project in the making. I am very broke so this could take weeks up to months to finish. But I figured I would document it from the beginning.

These first few pictures I will be showing u are just rough drafts and I will be making some changes. The plans aren't 100% mine as I have taking ideas and 3d models from others. Which I will give credit too in due time.

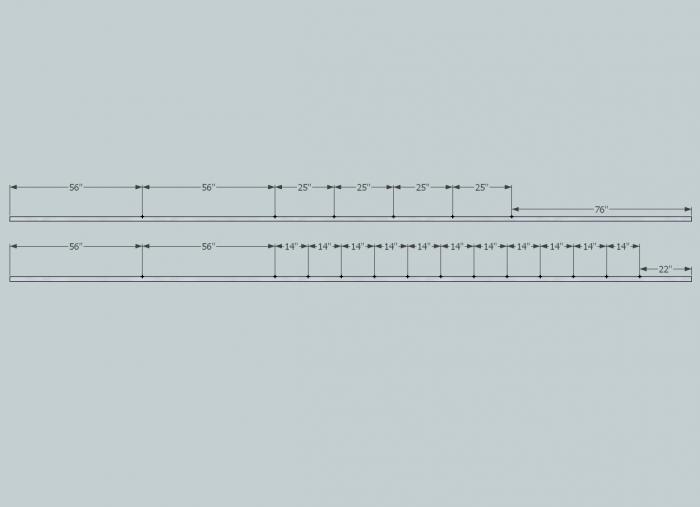

So I will show u the first rough drafts pictures I have. Also I love criticism an any ideas or revisions u have tell me. The pictures don't say on ther but I will be using 2 x 2 x (14 gauge) steel tubing for the frame. And instead of the banjo burners. I have already purchased plain ol propane burners and will have pictures of what I have so far. Eventually I will replace those with a better burner.

I debating on a herms system for mash and possible near full automation in the long run. And have a Arduino that I plan on using for this project.

Edit: Changed my Rough Draft to make things more efficient with the cuts and reduce the cost of the frame

These first few pictures I will be showing u are just rough drafts and I will be making some changes. The plans aren't 100% mine as I have taking ideas and 3d models from others. Which I will give credit too in due time.

So I will show u the first rough drafts pictures I have. Also I love criticism an any ideas or revisions u have tell me. The pictures don't say on ther but I will be using 2 x 2 x (14 gauge) steel tubing for the frame. And instead of the banjo burners. I have already purchased plain ol propane burners and will have pictures of what I have so far. Eventually I will replace those with a better burner.

I debating on a herms system for mash and possible near full automation in the long run. And have a Arduino that I plan on using for this project.

Edit: Changed my Rough Draft to make things more efficient with the cuts and reduce the cost of the frame