I took my first shot at AG brewing using BIAB method today. Below is the recipe I used: (Trying to make a Pale Ale)

9 Lbs Pale 2-row

1 Lbs Crystal 60L

12oz Carapils

Mashed at 152F for 85 minutes, did not do a mash out.

My Water Volume called for 7 gallons but due to high boil off I went with 8 gallons to start. I squeezed the hell out of the bag and felt like I got most of it out. The grain was not double crushed so I expected efficiency of around 60%, I stirred multiple times and my kettle held good temp (15 gallon SS kettle).

Boiled for 60m, starting boil volume was just under 7 gallons which is what I expected and was happy with.

Hop additions:

Summit 1oz (60m)

Cascade .5oz (15m)

Cascade .5oz (1m)

Added 1 tablet of whirlfloc at 15m

Using a wort chiller, chilled to 75F, took about 25 minutes total.

Transferred to sanitized glass 6.5 gallon carboy using tubing and ball valve directly from kettle, did not filter anything.

Hydrometer reading pre-boil showed 1.030 which I was not expecting, also checked on my refractometer and got the same so I am quite sure it's valid, however, thought possibly was lower due to the extra water I used.

I ended up with almost exactly 5 gallons after boil off and cooling so I felt like I hit what I wanted to but I was busy and forgot to get another sample to check OG. I am contemplating somehow getting a sample out of the carboy but I don't have a thief so thinking this one through, I don't need much because I can just use the hydrometer.

Am I right in that a 1.030 SG with 7 gallons is about 54% efficiency?

And....Is it worth it at this point to risk the batch on getting a sample to check OG of the boiled wort?

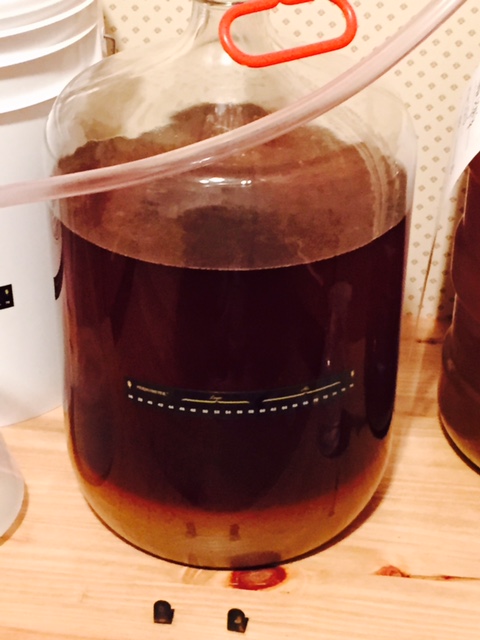

Posting a picture below because I was expecting a much lighter color on the wort, is this common for a pale ale?

9 Lbs Pale 2-row

1 Lbs Crystal 60L

12oz Carapils

Mashed at 152F for 85 minutes, did not do a mash out.

My Water Volume called for 7 gallons but due to high boil off I went with 8 gallons to start. I squeezed the hell out of the bag and felt like I got most of it out. The grain was not double crushed so I expected efficiency of around 60%, I stirred multiple times and my kettle held good temp (15 gallon SS kettle).

Boiled for 60m, starting boil volume was just under 7 gallons which is what I expected and was happy with.

Hop additions:

Summit 1oz (60m)

Cascade .5oz (15m)

Cascade .5oz (1m)

Added 1 tablet of whirlfloc at 15m

Using a wort chiller, chilled to 75F, took about 25 minutes total.

Transferred to sanitized glass 6.5 gallon carboy using tubing and ball valve directly from kettle, did not filter anything.

Hydrometer reading pre-boil showed 1.030 which I was not expecting, also checked on my refractometer and got the same so I am quite sure it's valid, however, thought possibly was lower due to the extra water I used.

I ended up with almost exactly 5 gallons after boil off and cooling so I felt like I hit what I wanted to but I was busy and forgot to get another sample to check OG. I am contemplating somehow getting a sample out of the carboy but I don't have a thief so thinking this one through, I don't need much because I can just use the hydrometer.

Am I right in that a 1.030 SG with 7 gallons is about 54% efficiency?

And....Is it worth it at this point to risk the batch on getting a sample to check OG of the boiled wort?

Posting a picture below because I was expecting a much lighter color on the wort, is this common for a pale ale?