KPSquared

Well-Known Member

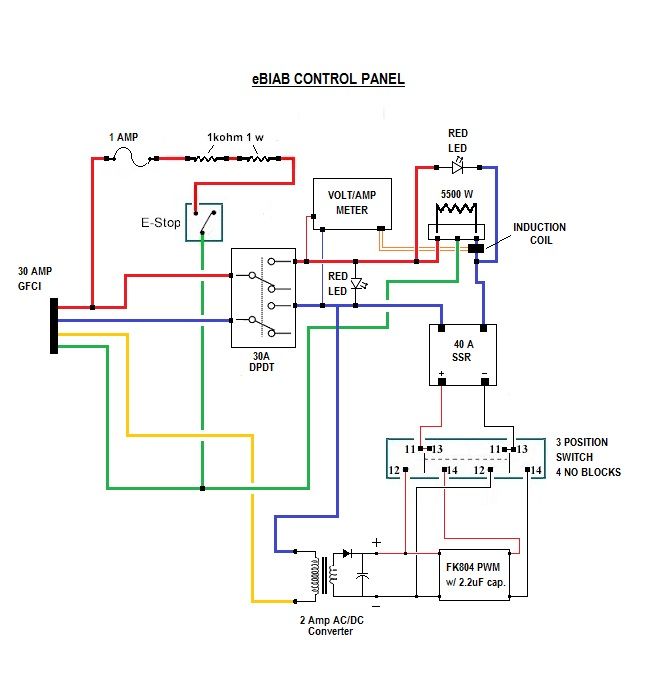

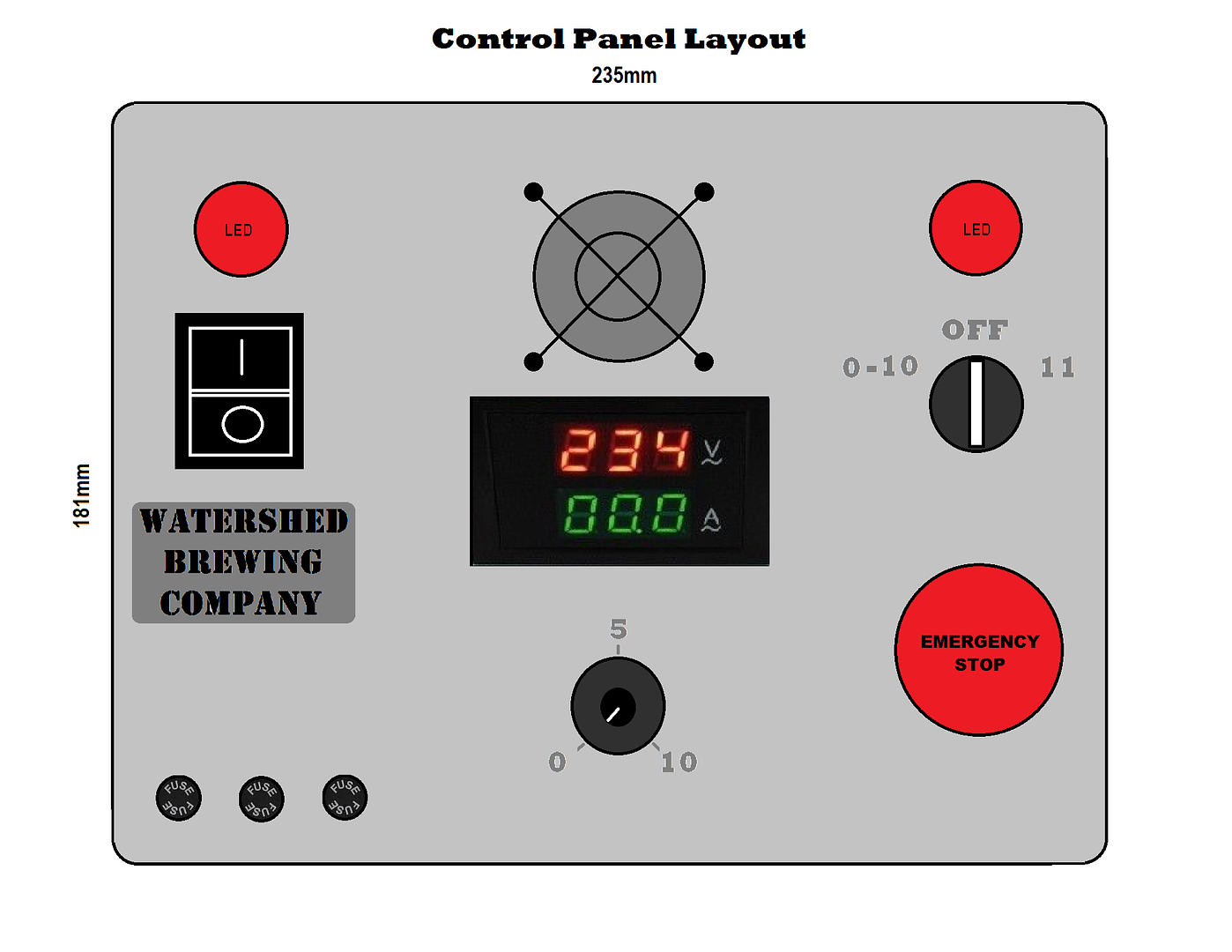

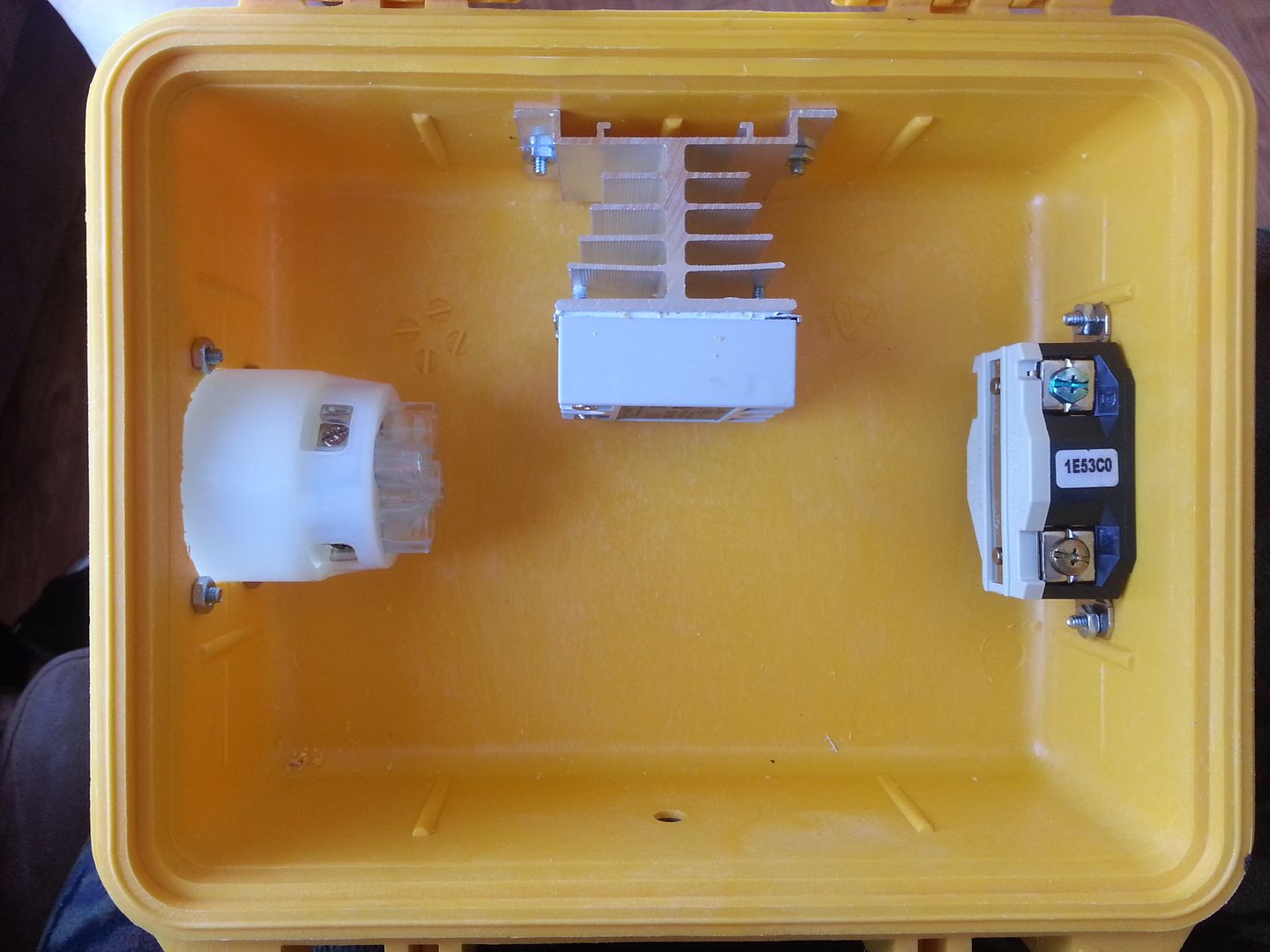

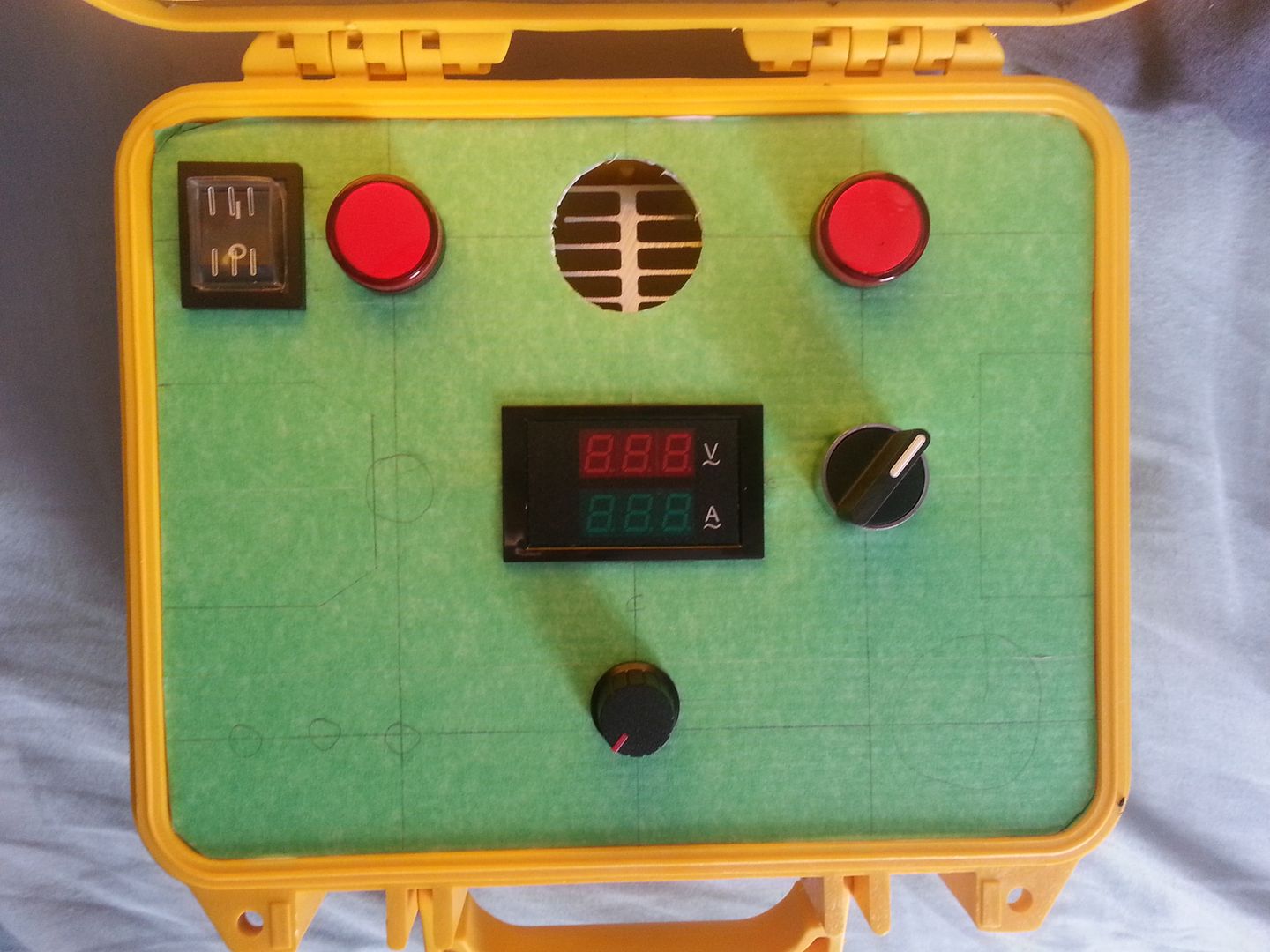

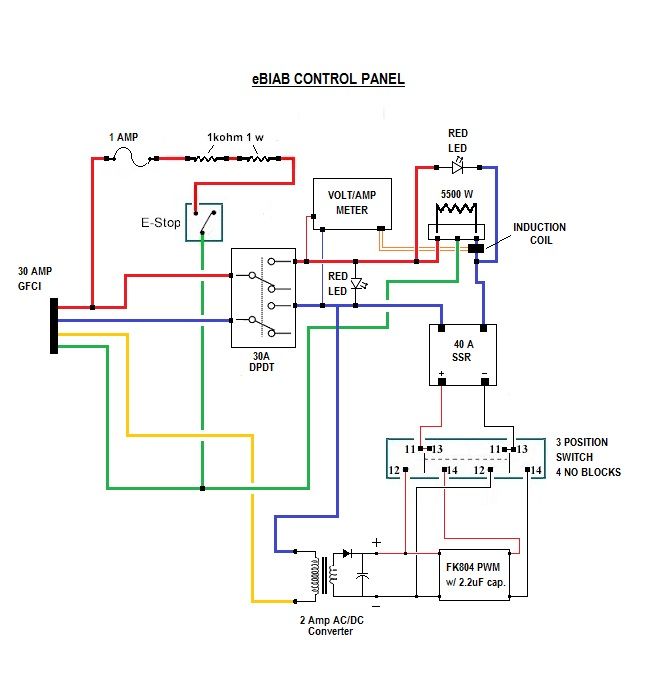

Looking for opinions on the wiring diagram I just finished. This is my plan for my "Phase 1" control panel for my eBIAB set-up. Plannig for PID, Pump, Timer etc. at a later date. . .

Any questions or suggestions feel free. The 3 way switch is to allow 100% power to the element which apparently the PWM won't do.

Thanks to PJ and Kal for all the information you guys have put on the interwebs. . . I've just scavenged and canabalised your stuff for this.

Any questions or suggestions feel free. The 3 way switch is to allow 100% power to the element which apparently the PWM won't do.

Thanks to PJ and Kal for all the information you guys have put on the interwebs. . . I've just scavenged and canabalised your stuff for this.