PrestigeWorldwide

Member

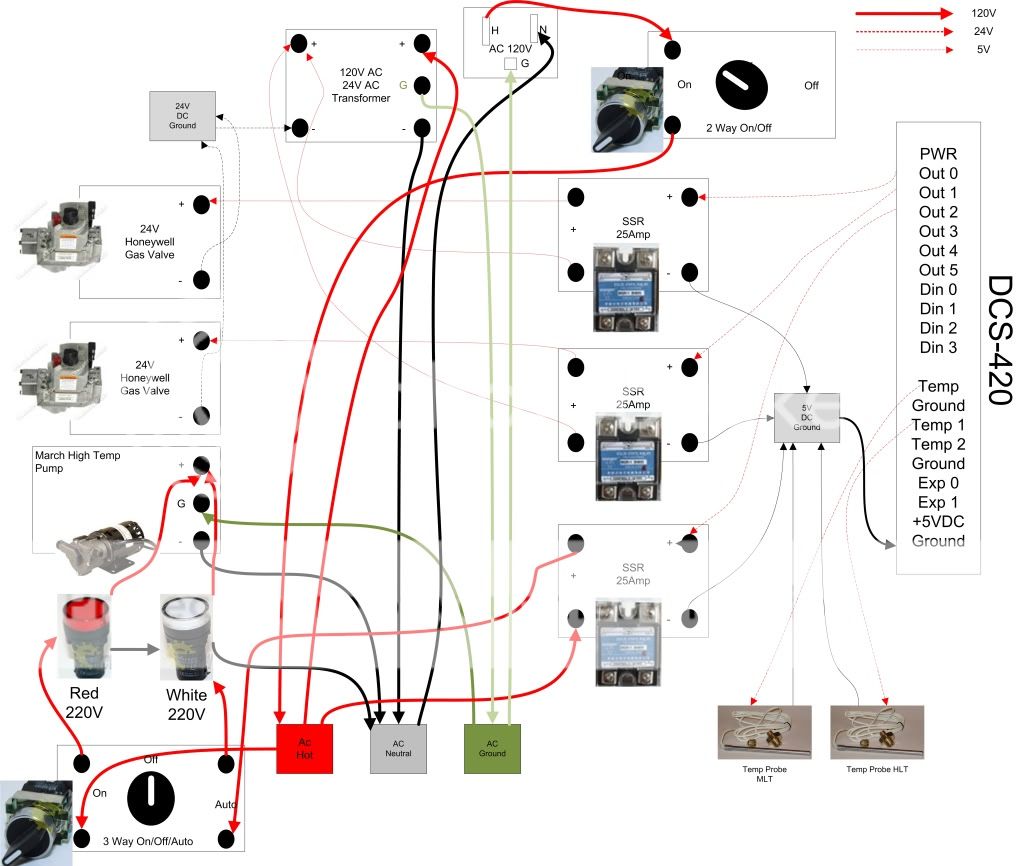

I need some direction. I dream of an automated HERMS system powered by BCS-460. I need a good dummy guide for building this. Simplicity is what i want, something like this and this. I'm still too confused to ask specific questions. Looking for some good threads to read.

Edit: I want gas powered. Leaning towards Natural Gas, so i dont need to refill propane.

Edit: I want gas powered. Leaning towards Natural Gas, so i dont need to refill propane.