jsguitar

Well-Known Member

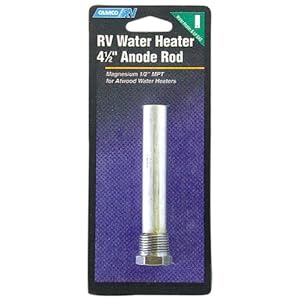

You'll be set. How are you planning on installing the anode?

Mine are working great.

Just brewed again with them today. I filled both my HLT and BK with strike and sparge water last night and not a speck of rust.

Thanks bbognerks for the idea!

Mine are working great.

Just brewed again with them today. I filled both my HLT and BK with strike and sparge water last night and not a speck of rust.

Thanks bbognerks for the idea!