twigboy2000

Well-Known Member

Just curious how everyone handles this.

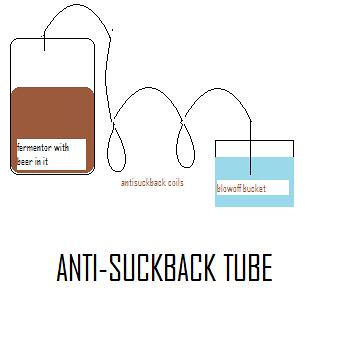

I've got two carboys of lambic going in the basement beer cave and I've noticed that this time of year when temp starts to swing my airlocks start to suck back in.

With the cold snap we had this past week it pulled a little of the Starsan into the carboy. I'm not terribly worried about it, but I am considering just putting one of those universal stoppers with an oak dowel driven through it for the long haul instead of the airlock.

I don't think the beer is going to off-gas much more at this point, as it doesn't seem to be generating positive pressure inside anymore.

Thoughts? I really want to be careful here since it is such a long term investment.

-chuck

I've got two carboys of lambic going in the basement beer cave and I've noticed that this time of year when temp starts to swing my airlocks start to suck back in.

With the cold snap we had this past week it pulled a little of the Starsan into the carboy. I'm not terribly worried about it, but I am considering just putting one of those universal stoppers with an oak dowel driven through it for the long haul instead of the airlock.

I don't think the beer is going to off-gas much more at this point, as it doesn't seem to be generating positive pressure inside anymore.

Thoughts? I really want to be careful here since it is such a long term investment.

-chuck